Material Science and Engineering

All-in-one transparent transistors

Small tweaks in component ratios generate electronically different layers from the same material to create transparent transistors.

Worldwide demand is growing for transparent conducting oxides for use in solar cells, flat panel displays, smart windows and semiconductor-based consumer electronics. KAUST researchers have engineered a zinc-oxide-based transparent material that displays tunable electronic properties depending on the tweaking of a new type of dopant.

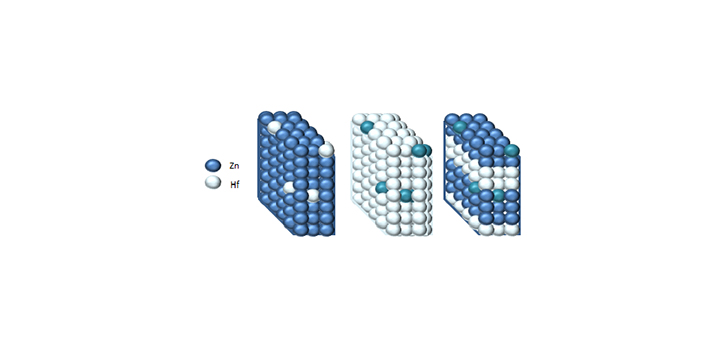

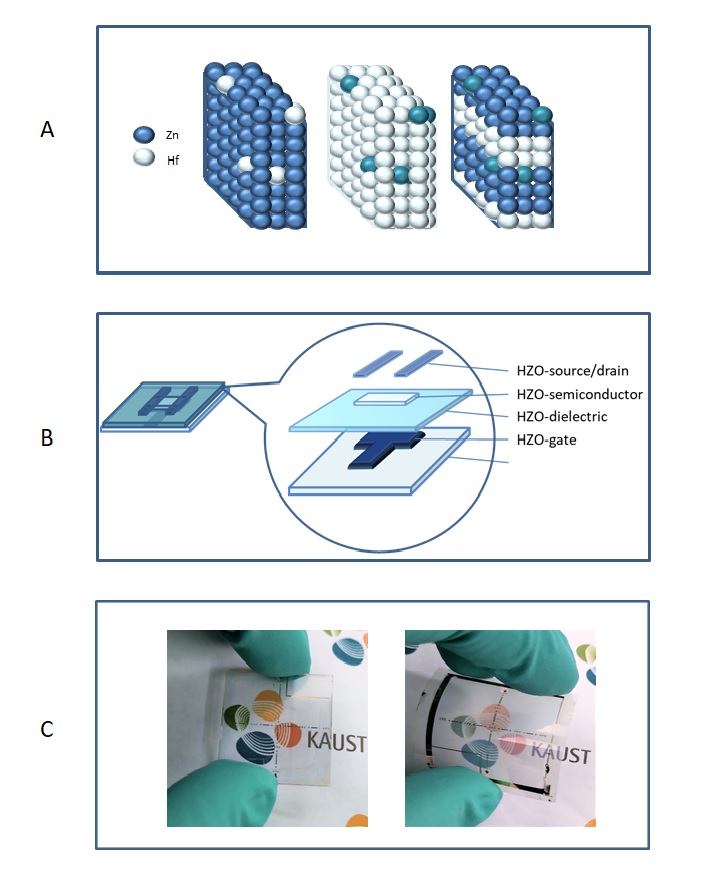

Panel A: Varying hafnium and zinc precursor ratios produce conducting (left), insulating (center) and semiconducting HZO materials (right). Panel B: Hafnium–zinc-oxide layers containing different metal ratios generate transparent thin-film transistors. Conducting layers provide source, drain and gate electrodes while insulating and semiconducting materials lead to gate dielectric and semiconducting channels, respectively. Panel C: The all-HZO transistors provide fully transparent devices with outstanding electrical properties on glass (left) and plastic supports (right).

Panels A and C reproduced with permission from reference 1. Panel B modified by Felaniaina Rakotondradany,© 2018 Wiley VCH.

Transparent electronics rely on indium tin oxide, a transparent and electrically conductive material that has an exorbitant cost due to the scarcity of indium. Zinc-oxide-based materials, such as hafnium-doped zinc-oxide materials, are expected to offer affordable, green and abundant alternatives to indium tin oxide. However, hafnium-doped zinc-oxide materials typically require high deposition temperatures and display inadequate performance for real-life device applications.

A team led by Husam Alshareef has developed an approach that generates transparent thin-film transistors from a single hafnium–zinc oxide (HZO) composite by simply varying metal oxide ratios in the different transistor layers.

Thin-film transistors generally comprise electrode, dielectric and channel layers that are deposited on a substrate from various conducting, insulating and semiconducting materials. They also require different reactors and thin-film deposition equipment. “The electronic properties of HZO can be tuned from conducting to semiconducting to insulating in a highly controlled fashion by simply changing the zinc-oxide/hafnium-dioxide precursor ratio,” says Ph.D. student Fwzah Alshammari, who performed most of the experiments. So the entire transistor is made from one binary oxide in a single reaction chamber. “This ultimately reduces the fabrication cost and time, which are crucial for mass production,” she adds.

The all-HZO transistors exhibit excellent electrical properties on glass and plastics, demonstrating their potential for high-resolution transparent and flexible displays. They also show outstanding performance when incorporated in circuits, such as inverters and ring oscillators, suggesting their viability and scalability.

The team is planning to fabricate more complex circuits over larger areas to demonstrate the full potential of their approach for consumer electronics.

References

-

Alshammari, F.H., Hota, M.K. & Alshareef, H.N. Transparent electronics using one binary oxide for all transistor layers. Small 14,1803969 (2018).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics