Material Science and Engineering

A simple additive to improve film quality

Simple chemicals called glycol ethers help make better perovskite thin films for solar cells.

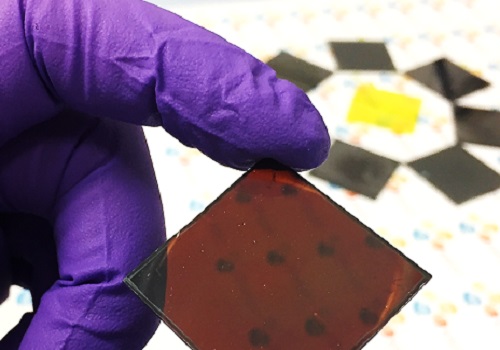

Photovoltaic wafers developed for use in solar cells. The new perovskite thin films have improved structure and efficiency

© 2017 Frédéric Laquai

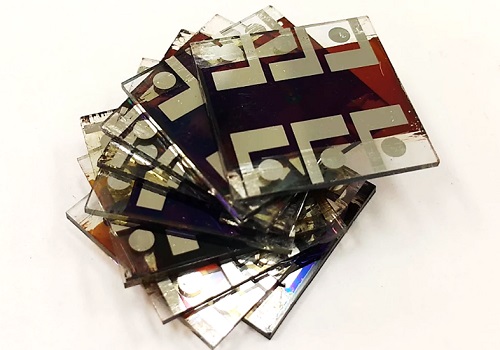

Photovoltaic devices produced with the assistance of simple additives.

© 2017 Frédéric Laquai

Thin films for use in solar cells are more effective when simple chemicals called glycol ethers are added to the film-forming mix, a KAUST team has found.

“This is an unexpected discovery,” says Esma Ugur, a PhD student in the KAUST Solar Center team that observed the effect. “It yields more uniform thin films with improved structure and efficiency.”

Perovskites are materials with the same crystal structure as the naturally occurring perovskite calcium titanium oxide. Various metal halide perovskites are proving useful for harvesting light energy that can then be used to create electric current—the basic operating principle of a solar cell. The perovskites can be added as a thin layer on top of conventional solar cells because they can harvest the blue wavelengths of light to complement the energy of red wavelengths captured by traditional materials.

“Our aim was to improve the quality of perovskite thin films,” says Ugur. The team decided to add glycol ethers to the manufacturing process because they knew these chemicals had previously been used to help create layers of metal oxides.

By trying different glycol ether mixtures and conditions, the researchers eventually gained better control over the formation of their perovskite thin films because they were able to significantly improve the structure and alignment of the perovskite grains. This increased the reproducibility and efficiency of the perovskites such that they performed more efficiently in solar-cell applications.

The procedure also operates at lower temperatures than alternatives, which is an important factor in improving cost effectiveness.

To date, the team has only made small lab-scale devices (see image). The next key challenge, explains Frédéric Laquai, who leads the KAUST Solar Center team, is to scale this up for commercial applications. To achieve this, they will need to find ways to overcome the instability of their perovskites.

“We have several groups in the KAUST Solar Center working on that issue and on other needs for future commercial development” says Laquai. He emphasizes that perovskites are a high-priority research area for the Center with potential for applications beyond just solar cells. “Perovskites have many interesting optical and electronic properties, which may make them useful for applications that we have not even thought about,” he explains. Laquai also highlights the collaborative character of the projects at the KAUST Solar Center. He cites the ability to draw on the expertise of specialists from several different fields as key factors contributing to their success.

References

- Ugur, E., Sheikh, A.D., Munir, R., Khan, J. I., Barrit, D, Amassian, A. & Laquai, F. Improved morphology and efficiency of n-i-p planar perovskite solar cells by processing with glycol ether additives. ACS Energy Letters 2, 1960–1968 (2017).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics