Material Science and Engineering

Fewer steps to a shining success

Streamlining the process to fabricate quantum dot devices could improve their potential as low-cost, flexible solar cells.

Harnessing the sun’s energy to generate electricity could be the answer to the world’s growing demand, but only if the process is commercially viable. Researchers from KAUST

are trying to streamline the manufacture of more efficient and versatile alternatives to conventional silicon solar cells.

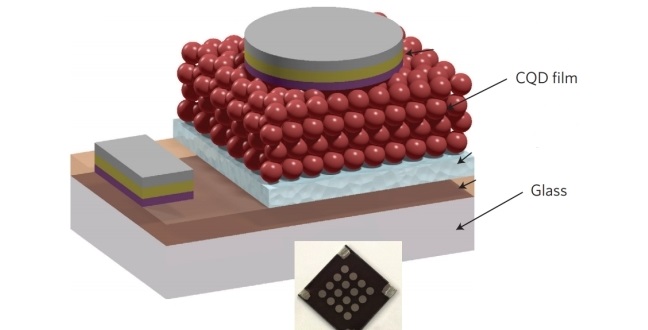

Colloidal quantum dots – tiny semiconductor crystals that can capture and convert light into electrical energy – are attracting a lot of research interest because their

size allows them to be fabricated like an ink on to a flexible surface cheaplyand easily. Yet efficiency and production issues still limit their potential.

“The ability to use quantum dots to harvest the near-infrared of the solar spectrum opens new opportunities to generate electricity while also managing heat, both of which are particularly welcome in Saudi Arabia,” explains Aram Amassian from KAUST’s Solar and Photovoltaic Engineering Research Center.

These quantum dots – due to quantum effects related to their small size – are much better at absorbing light than regular layers of semiconductors. However at less than 10 percent, their power conversion efficiency is fairly poor, and the dozens of manual steps required to fabricate the light-absorbing layer makes them very expensive to manufacture.

So Amassian’s team, along with collaborators from the University of Toronto in Canada, have tried to find a streamlined method to fabricate quantum dot solar cells to make them

more commercially viable.

One recent breakthrough was to introduce organic ligand molecules which drew the quantum dots very closely together to allow electrical charges to be transported across the solar cell. This process used a solvent, methanol, to deliver the ligand molecules into the solar cell. However if the quantum dots were exposed to the solvent for too long, they were chemically damaged and required labor-intensive, repetitive and wasteful procedures to

fix.

To look for efficiency gains Amassian’s team focused on the solvent. They showed by switching to a more neutral, organic solvent, acetonitrile, the performance of the solar cells improved considerably. Use of the milder solvent also meant that thicker layers of quantum dots could be treated with ligands without compromising efficiency.

Development of quantum dot solar cells still has a long way to go, but such advances in performance and fabrication suggest that new technologies are possible beyond the conventional solar cells now found on rooftops, says Amassian. “These lessons will be crucial in the development of solution-processed, semi-transparent quantum dot

solar cells, which can be integrated into windows, buildings and transportation infrastructure in sunny and warm climates.”

References

-

Kirmani, A. R., Carey, G., Abdelsame, M., Yan, B., Cha, D., Rollny, L.R., Cui, X., Sargent, E.H. & Amassian, A. Effect of solvent environment on

colloidal-quantum-dot solar-cell manufacturability and performance. Advanced Materials 26, 4717–4723 (2014).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics