Material Science and Engineering

A good idea bubbles to the surface

Imploding bubbles improve the growth of single-crystalline perovskite solar cell thin films.

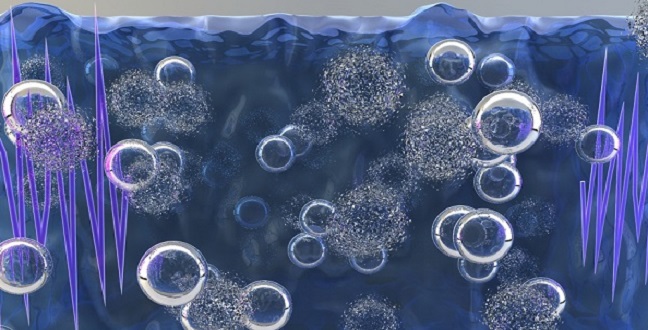

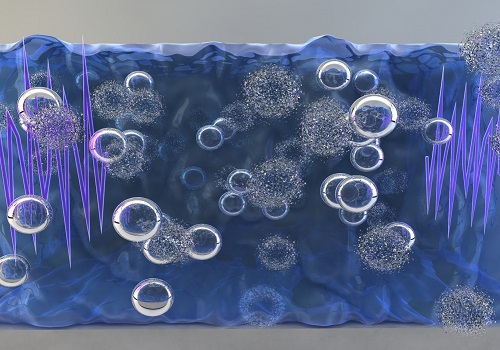

Illustration of the growth process using bubbles. (a) bubbles are created by brief ultrasonic pulses.

(b) The bubbles implode, sending jets of growth liquid towards the substrate.

(c) Monocrystalline thin films are grown.

Reproduced with permission from reference 1 © 2016 John Wiley & Sons.

Single thin-film crystals are required to utilize promising hybrid organic/inorganic perovskite materials to develop solar cells. KAUST researchers have now shown how imploding bubbles in a solution can grow single crystals of the preferred orientation for manufacturing thin films.

Hybrid organic/inorganic perovskite materials are some of the most promising solar cell materials, as they are easy to produce and show excellent solar light conversion efficiencies.

“Our monocrystalline films provide a platform to directly implement perovskite single crystals and to elucidate their promises and challenges for solar cells,” said Osman Bakr, KAUST associate professor of material science and engineering who also led the research study.

Hybrid perovskite materials can easily be fabricated on a large scale from a solvent solution. However, this process typically produces polycrystalline perovskite films that have a smaller solar-light conversion efficiency than monocrystalline materials because the boundary between crystalline grains leads to losses. In particular, growth of single-crystalline perovskite solar cell films has not yet been achieved on top of other materials, which is a requirement for practical devices.

The researchers have now achieved the fabrication of single-crystalline perovskite thin films by applying ultrasonic pulses to the growth solution. The pulses induce tiny bubbles that implode after a short time, releasing energy into the surrounding solution. If a bubble is close to the substrate surface, the energy from the implosion creates tiny jets within the growth solution that are projected towards the substrate. Those jets induce the nucleation of perovskite crystals on the surface.

The films grown by this process are remarkably uniform and monocrystalline. Also, because of the directional impact of the liquid jets on the surface, the growth process is independent of the substrate properties and therefore leads to a favorable uniform orientation of the crystals. This alignment means they can support the transport of electrical charges across the device.

The thin films show very good conversion efficiencies. In test devices, a conversion efficiency of 6.5 percent was achieved, which is considerably higher than the 5.6 percent previously achieved from comparable polycrystalline samples.

There are further hurdles, however, Bakr noted. “The biggest challenge of our method is the limited lateral dimensions that we can reach, which are only about two millimeters. The next step of our study is to improve the growth to reach centimeter-scale monocrystalline films or even larger sizes, which is essential for the large scale application of these monocrystalline films in industry,” he said.

References

-

Peng, W., Wang, L, Murali, B., Ho, K.-T., Bera, A. et al. Solution-grown monocrystalline hybrid perovskite films for hole-transporter-free solar cells. Advanced Materials 28, 3383–3390 (2016).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics