Mechanical Engineering

Putting the squeeze on soot

Understanding the effect pressure has on soot production during fuel combustion could help reduce polluting emissions.

Running diesel engines and gas turbines at high pressure to boost power output and efficiency is harmful for the environment. Burning fuel at high pressure can significantly change the soot particles that are produced, William Roberts from the KAUST Clean Combustion Research Center and his team has shown. Studying the factors affecting soot formation should lead to new ways to curb soot emissions, says Hafiz Amin, first author of the paper.

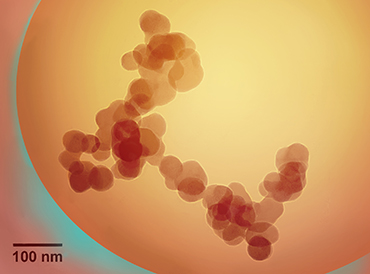

Soot is a major global pollutant, harmful to human health and the second biggest contributor to global warming after carbon dioxide. The complex substance comprises individual nanoparticles that are linked together in chain-like structures called fractal aggregates. Because the effect of soot particles on human health is highly dependent on the soot structure, the team was motivated to understand the formation processes. “The formation of the soot is the key to controlling its emissions,” Amin says. But the effect that elevated pressure has on soot production is not well understood. Roberts and his team developed an efficient method for soot sampling that provides new insights into soot formation.

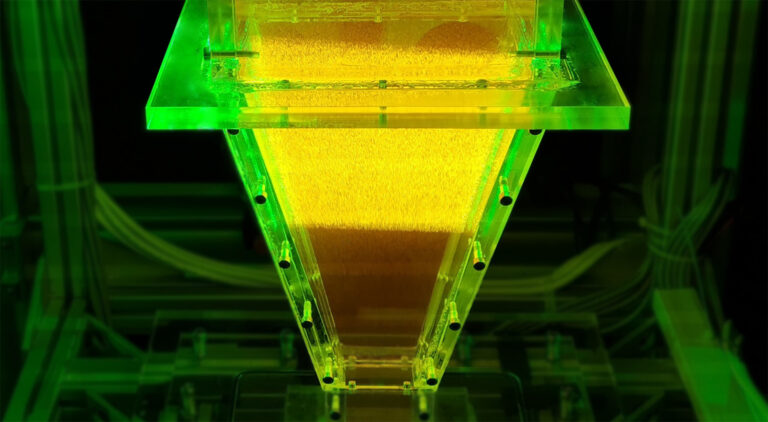

The team developed a way to sample, at pressures up to 10 atmospheres, the soot particles produced in a laminar flame called a counterflow diffusion flame. The counterflow burner produces a horizontal, circular shaped flame that is stable and uniform. “The counterflow flame allows us to control the fluid dynamics of the flame and requires less computational power for modeling,” explains Anthony Bennett, co-author of the paper and current Ph.D. student in Roberts’ team. The researchers collected soot from the flame using a fine carbon-coated copper mesh held by a pneumatically powered robot arm that rapidly shoots out to collect a soot sample with minimal disturbance to the flame.

Anthony Bennet (left) and Bill Roberts with the pressure vessel the group used to perform the experiments.

© 2018 KAUST

The team analyzed their soot samples using transmission electron microscopy and observed that elevated pressure significantly increased soot particle size. The mean particle diameter of 17.5 nanometers at 3 atmospheres of pressure rose to 47 nanometers at 10 atmospheres.

“This shows the importance of the influence of pressure on soot emissions,” Bennet says.

Now that they have developed an effective high-pressure experimental setup and soot-sampling procedure, the team has many more experiments planned, Amin says. “We would like to extend the investigations to a pressure of 40 atmospheres, which is relevant to the operating pressure of gas turbines,” he says.

The team would also like to investigate how different fuel chemistry and residence times influence soot production at elevated pressure. “Our current experimental facilities provide the control to perform such investigations,” Amin says.

References

- Amin, H.M.F., Bennett, A. & Roberts, W.L. Determining fractal properties of soot aggregates and primary particle size distribution in counterflow flames up to 10 atm. Proceedings of the Combustion Institute 37, 1161-1168 (2019).| article

You might also like

Mechanical Engineering

Green hydrogen from fluctuating power sources

Mechanical Engineering

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering