Material Science and Engineering

Flexible transistor shows memory potential

Multitasking ferroelectric polymer could store or process data faster than its rivals.

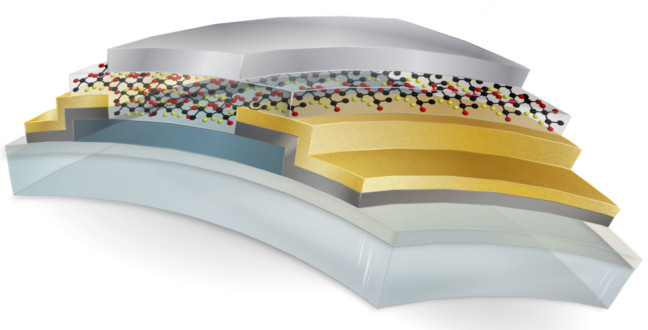

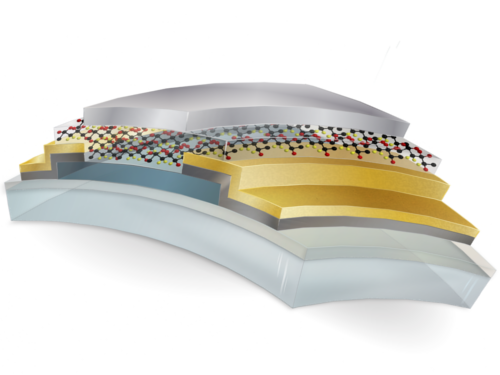

The flexible transistor rests on a polyimide substrate, and includes layers of tin oxide (dark blue) and the ferroelectric polymer P(VDF-TrFE) (red, black and yellow molecular structure).

© KAUST

A record-breaking transistor developed by KAUST researchers shows potential as a component in flexible electronic devices.

Bendable gadgets that can be rolled up or wrapped over uneven surfaces — with diverse and far reaching applications from cell phones to satellites — need high-performance memory and logic components that are equally malleable.

These parts could be made from transparent ferroelectric polymers, which have an intrinsic polarization that can be switched either way by voltage. Used in ferroelectric field-effect transistors (FeFETs), each polarization state can represent some data — a ‘1’ or ‘0’ — allowing it to store and process information.

Power-efficient circuits typically require two types of transistors: those that transport electrons, and those that transport positively-charged ‘holes’ in their structure. But these holes have a poor mobility in FeFETs, which impairs the transistor’s performance.

Husam Alshareef and colleagues from KAUST’s Physical Science and Engineering Division have now developed a hybrid FeFET that teams a ferroelectric polymer with ‘p-type’ tin oxide, in which the positively-charged holes in its crystal structure outnumber its electrons. This gives the transistor 10 times greater charge mobility than comparable devices, which increases its operating speed1.

“With this development, both types of ferroelectric transistors can now be combined to make power-efficient and more complex circuits,” says Alshareef. The FeFETs can also play a dual role in these circuits, he adds, acting as both transistors and memory components.

The team initially built an FeFET on a thin sheet of glass, using a 30 nanometer-thick layer of tin oxide and a 300 nanometer-thick coating of a ferroelectric polymer called P(VDF-TrFE) (see image). X-ray diffraction studies showed that the tin oxide layer contained traces of metallic tin, while atomic force microscopy (AFM) revealed that the tin oxide surface was very smooth. Both are essential in achieving high charge mobility.

AFM also indicated that the polymer formed relatively large grains of about 160 nanometers, which maximizes its ferroelectric polarization and improves its performance as a switchable memory component.

The manufacturing process required relatively low temperatures of around 200 degrees Celsius, which allowed the team to build a similar device using a flexible substrate material known as a polyimide. This produced a rougher tin oxide layer, which reduced electron mobility but the researchers found that the device was still flexible — it could be bent 100 times without reduced performance.

Alshareef explained that the next steps for them is to improve the transistor’s performance and then he says they will tackle making more complex circuits.

References

- Caraveo-Frescas, J. A., Khan, M. A. & Alshareef, H. N. Polymer ferroelectric field-effect memory device with SnO channel layer exhibits record hole mobility. Scientific Reports 4, 5243 (2014).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics