Mechanical Engineering

Igniting future fuel research

Simple two-component mixtures are good surrogates for studying the ignition properties of next-generation gasolines.

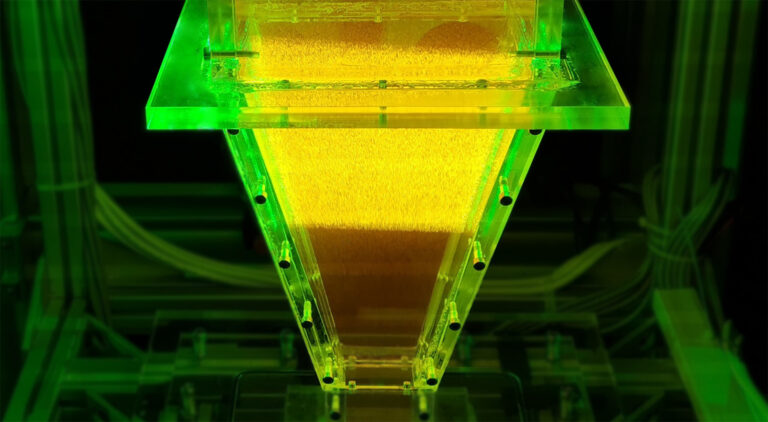

Students test fuel ignition chemistry using two shock tubes at the KAUST Clean Combustion Research Center.

© 2016 KAUST

A collaboration between KAUST and Saudi Aramco scientists to test future fuels could bring a new era of highly efficient gasoline engines.

Gasoline compression ignition (GCI) is an experimental engine technology that could consume 25% less energy than a conventional automobile engine, suggests well-to-wheel lifecycle analysis. GCI uses a gasoline-type fuel, but rather than ignited with a spark, it is compression-ignited like diesel. GCI could therefore be a best-of-both-worlds engine technology: combining the fuel efficiency of diesel engines with the low NOx and soot-particle emissions of gasoline.

To optimally design a GCI engine, engineers need detailed knowledge of the low-octane gasoline fuel they would run on. Aamir Farooq at KAUST’s Clean Combustion Research Center, and his collaborators, have analyzed the combustion chemistry of two low-octane gasolines ignited under engine-relevant conditions. “Our focus was to probe the chemical kinetics of auto-ignition of two low-octane gasolines with widely different compositions but similar octane ratings,” says Tamour Javed, who worked on the project as part of his PhD research.

“To optimize the performance of GCI engines, we used high-fidelity predictive computer simulations,” explains Farooq. “A big part of such simulations is the description of fuel chemistry.” But a real gasoline fuel is much too complex a chemical mixture to simulate. “Instead, we try to formulate a simpler representation of the real fuel, known as a surrogate.”

The team compared each low-octane gasoline with a potential two-component surrogate, measuring how closely its ignition behavior mimicked the real fuel. In most conditions, the two-component surrogate proved to be a good representative of real low-octane fuel, its behavior only diverging at low ignition temperatures. “For higher accuracy at low temperatures, we proposed a multi-component surrogate,” Farooq says.

Although it will take a significant update in refinery infrastructure to bring low-octane fuels to market, in the short-term, low-octane fuels could be made by combining conventional fuels, Farooq adds. “Studies to test the feasibility of mixing diesel and gasoline fuels to match the characteristics of a low-octane gasoline are underway in our laboratory at KAUST.”

For Javed, meanwhile, there was also a personal benefit to the project; he recently took up a job with project partner Saudi Aramco after completing his studies “The project not only paved the way for my employment, but also it was a nice learning experience for a young researcher to interact with industry,” he says.

References

- Javed, T., Ahmed, A., Lovisotto, L., Issayev, G., Badra, J. Sarathy, M.S., & Farooq, A. Ignition studies of two low-octane gasolines. Combustion and Flame 185, 152–159 (2017).| article

You might also like

Mechanical Engineering

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering

Turbulent flow shows surprise patterns that could help boost efficiency

Mechanical Engineering