Chemistry

Shaping the future of purification

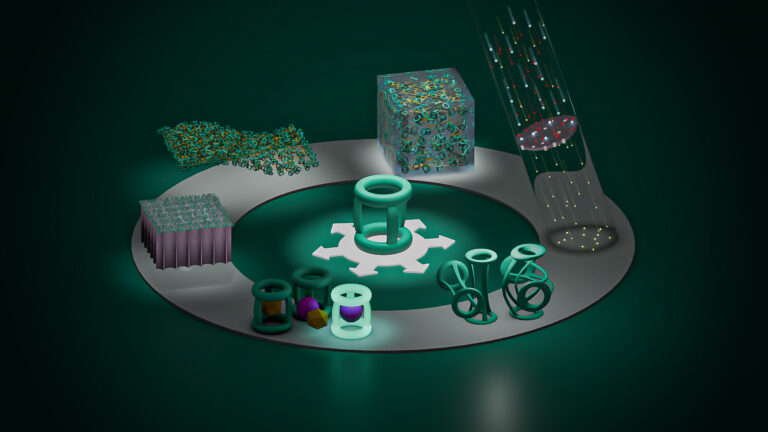

Porous MOFs enable simple molecular separations based on mismatches in physical profiles.

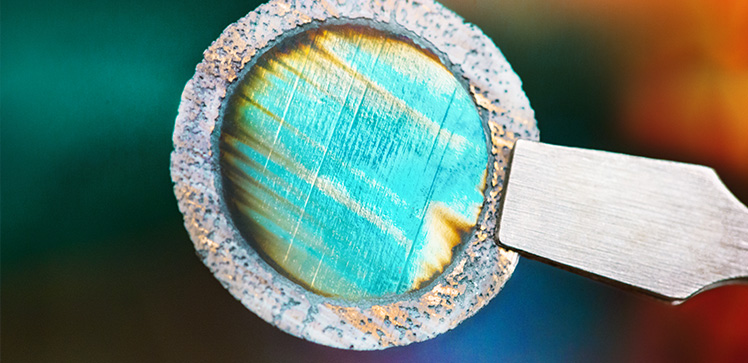

KAUST researchers have developed a MOF membrane that can purify natural gas. © 2022 KAUST. /en/article/1250/shaping-the-future-of-purification/en/article/1250/shaping-the-future-of-purification

KAUST researchers have developed a MOF membrane that can purify natural gas. © 2022 KAUST. /en/article/1250/shaping-the-future-of-purification/en/article/1250/shaping-the-future-of-purification

Impure chemical mixtures can now be separated based on differences in molecular silhouette. Membranes have been developed with nanoscale pores that match the shape of impurities in the mix so that only the impurity can pass through. KAUST researchers have suggested that the first application of these metal-organic framework (MOF) based shape-selective membranes could be energy-efficient, low-cost purification of natural gas.

MOFs are organic-inorganic hybrid crystalline porous materials that can feature different types of pores through their structure. By constructing MOFs from different organic and inorganic building blocks, researchers can finely tune the pore structure and aperture. MOF membranes have previously shown great potential for separating mixtures of molecules based on differences in their size or polarizability.

The cost of purifying methane using the team’s membrane was reduced by approximately 73 percent.

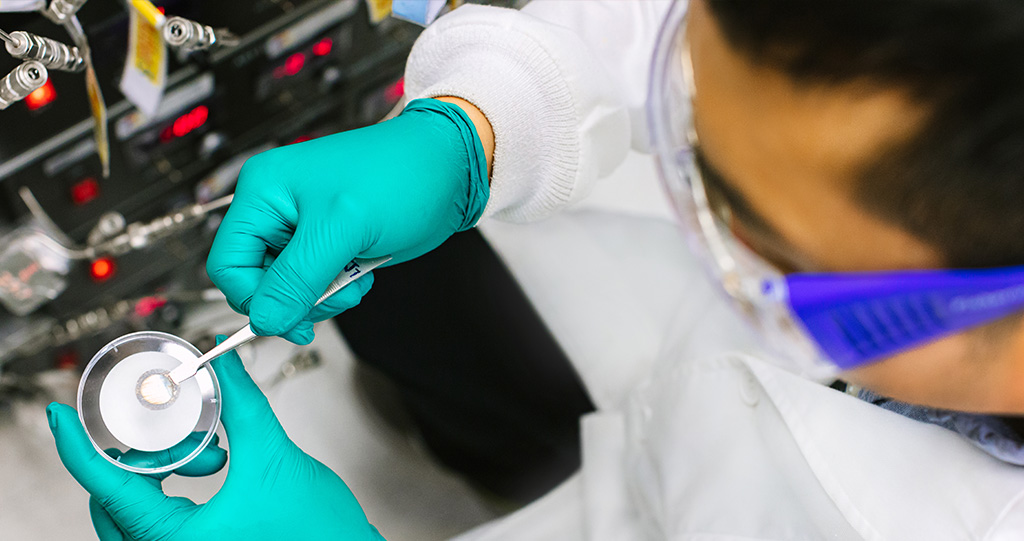

© 2022 KAUST; Anastasia Serin.

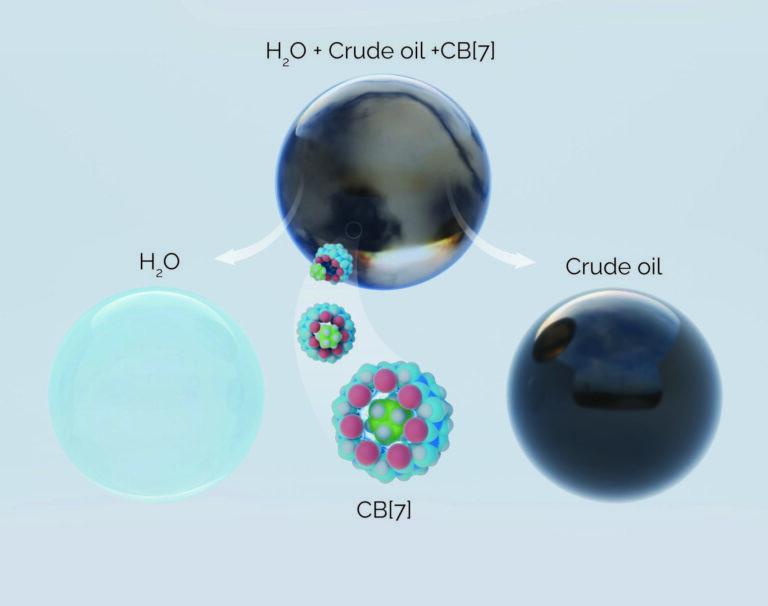

Natural gas, also known as methane, is predicted to play an increasingly important role in the global energy supply during the transition to renewables. Almost all natural gas reservoirs are contaminated with nitrogen. “The nitrogen dilutes the heating value of natural gas, so it has to be removed,” says Sheng Zhou, a Ph.D. student in Mohamed Eddaoudi’s lab, who led the research.

Nitrogen is chemically inert and similar in both kinetic shape and polarizability to methane, so cannot be removed by existing membranes. “For industrial natural gas purification, there needs to be nitrogen rejection units based on cryogenic distillation,” Zhou says. This ultra-low temperature separation technique is expensive and energy intensive.

The team, including Osama Shekhah (left) and Jiangtao Jia (right), designed their porous membrane to separate nitrogen from methane by exploiting the difference between the molecular shape of the gases.

© 2022 KAUST; Anastasia Serin.

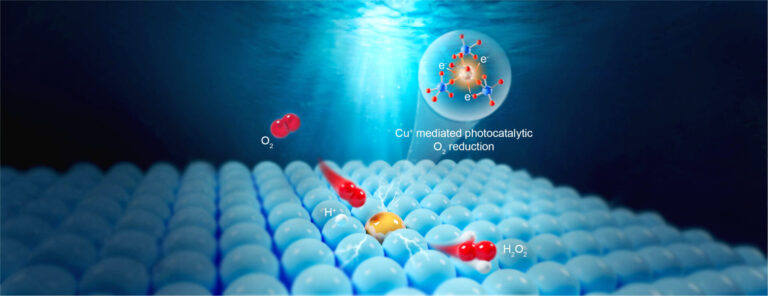

Eddauodi, Zhou and their colleagues have developed a highly efficient MOF-based method to purify methane. “We designed a porous membrane that separates nitrogen from methane by exploiting one significant difference between the molecules: their shape,” Zhou says.

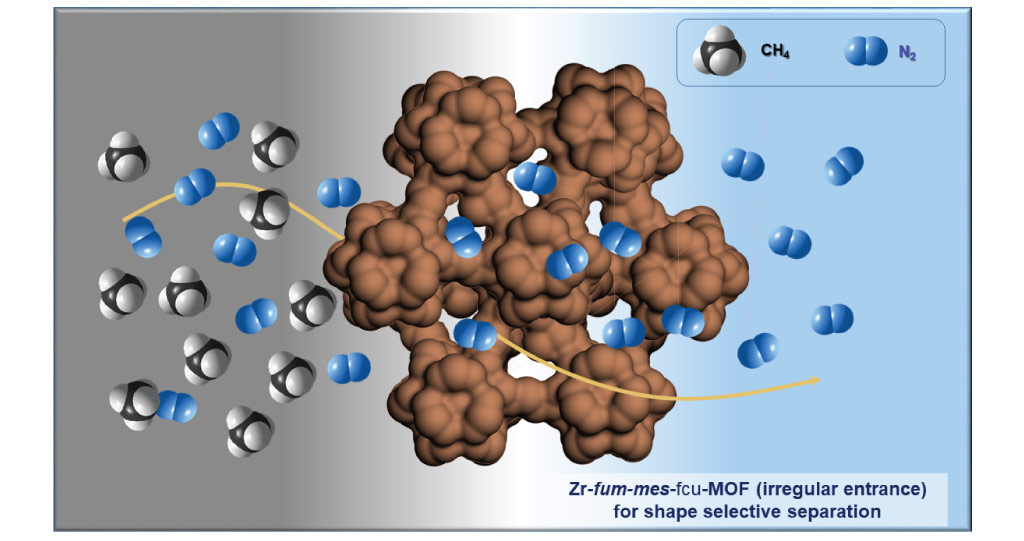

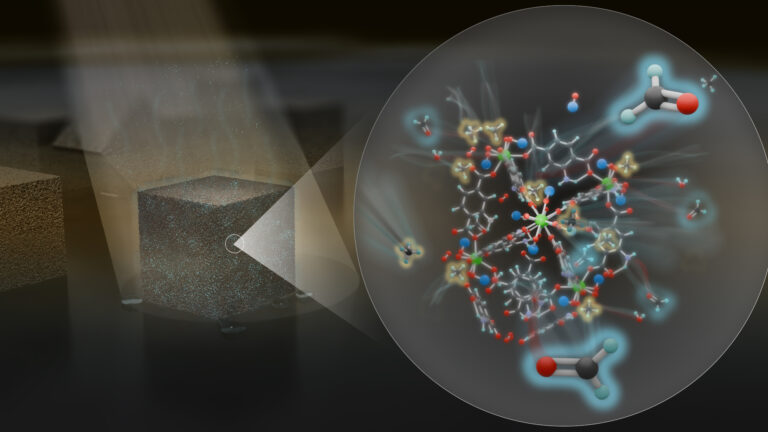

While nitrogen has a rod-like linear structure, methane has a triangular trefoil-type profile. The team created a new membrane material, named Zr-fum67-mes33–fcu-MOF, with asymmetric pores precisely shaped to block methane but allow nitrogen to pass through.

The team has now shown that, compared to cryogenic separation, the shape-selective MOF reduced purification costs by 66 percent for a methane stream containing 15 percent nitrogen.

Illustration of the new membrane material Zr-fum67-mes33–fcu-MOF.

© 2022 KAUST

Other potential impurities could also be removed. For methane contaminated with 35 percent carbon dioxide and 15 percent nitrogen, the purification cost was reduced by approximately 73 percent. “We saw a massive reduction in total purification cost when the membrane was used,” says Osama Shekhah, a senior research scientist in Eddaoudi’s lab.

Until now, shape difference in molecular mixtures has been largely ignored, Eddaoudi says. “Shape-mismatch induced separation is a totally new separation mechanism,” he says. “Once people focus on shape-mismatch separation, they may find many chemical mixtures, such as linear and branched hydrocarbons or aromatic chemicals, that could be efficiently separated using this concept.”

References

- Zhou, S., Shekhah, O., Ramírez, A., Lyu, P., Abou-Hamad, E., Jia, J., Li, J., Bhatt, P.M., Huang, Z., Jiang, H., Jin, T., Maurin, G., Gascon, J. & Eddaoudi, M. Asymmetric pore windows in MOF membranes for natural gas valorization. Nature 606, 706–712 (2022).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

Natural polymer boosts solar cells

Chemistry

Disruptive smart materials flex with real world potential

Chemistry

Catalysts provide the right pathway to green energy

Chemistry

Hollow molecules offer sustainable hydrocarbon separation

Chemistry

Maximizing methane

Chemistry

Beating the dark current for safer X-ray imaging

Chemical Engineering