Mechanical Engineering

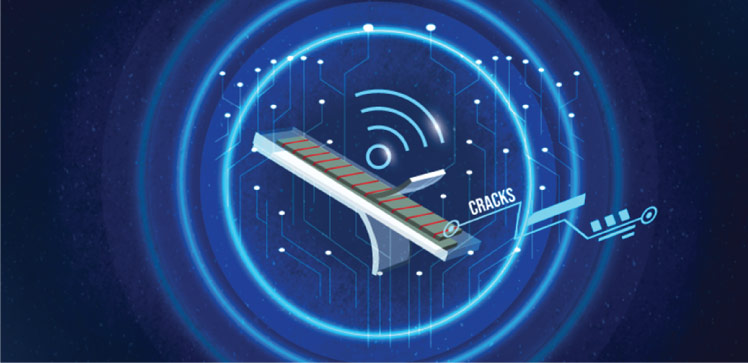

Wireless strain sensors cracked up to be better

Incorporating regular cracks in electrodes for wireless strain sensors brings surprisingly better sensitivity.

Controlling the structure of fragmented electrodes composed of carbon nanotubes could offer improved wireless monitoring of the strain on materials in a wide range of applications.

“This opens endless possibilities for every situation where accurate wireless monitoring of structures is important,” says Gilles Lubineau, Professor of Mechanical Engineering at KAUST.

Lubineau developed the technology with postdoc Hussein Nesser, who adds: “Our sensor can directly be used to assess, in-situ and with great accuracy, the strain exerted on materials.”

Monitoring the strains imposed on materials is crucial for checking the safety of everything from buildings and bridges to ships and aircraft. Strain sensors are also important subdevices for monitoring aspects of health, sports performance and robotics. Natural, manufactured and living structures are all exposed to stresses and strains that can compromise their integrity.

Most strain sensors are composed of a material that can convert physical deformation into changes in electrical resistance or capacitance. The resulting electrical signals have traditionally been carried to the detecting devices along wires, but more recently, wireless technology is bringing the obvious advantages of remote sensing. This is especially useful for detecting the strains on materials in difficult-to-reach locations, such as inbuilt structures, vehicles or inside the body.

“Our ultimate objective is to make a new generation of wire-free, battery-free and ultralow-cost sensors,”

Existing wireless systems, however, are beset by problems of low sensitivity. KAUST researchers have tackled these problems by introducing a special pattern of cracks into fragmented electrodes in a way that greatly increases the sensitivity of the electrical responses. While the team was working on such a concept in the past for resistive sensors, this is the first time it has been applied to capacitive sensors that are more suitable for passive wireless applications.

Their sensor is essentially an electrical capacitor with carefully fragmented electrodes made of carbon nanotube-containing paper. The electrical changes caused by different levels of strain generate signals that can be captured wirelessly by electromagnetic coupling.

“Our innovation brings high gauge factor to the world of wireless strain detection,” says Lubineau. Gauge factor describes the ratio of the generated electrical signal to the level of strain.

Having demonstrated their concept in principle, the researchers now plan to embed it into readily deployable systems suitable for commercialization. They will also investigate using it to detect other physical properties of materials in addition to strain.

“Our ultimate objective is to make a new generation of wire-free, battery-free and ultralow-cost sensors,” says Nesser.

References

-

Nesser, H. & Lubineau, G. Achieving super sensitivity in capacitive strain sensing by electrode fragmentation. ACS Applied Materials & Interfaces 13, 30, 36062–36070 (2021).| article

You might also like

Mechanical Engineering

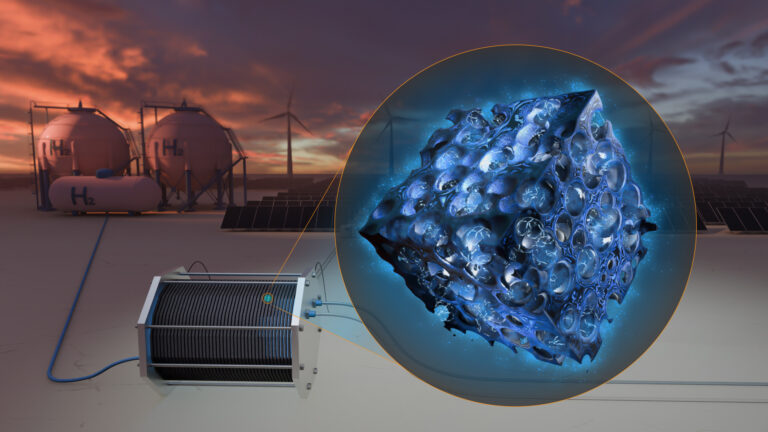

Green hydrogen from fluctuating power sources

Mechanical Engineering

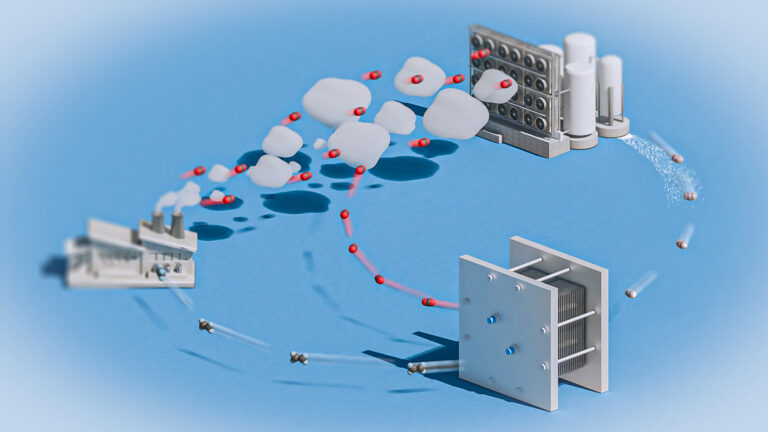

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

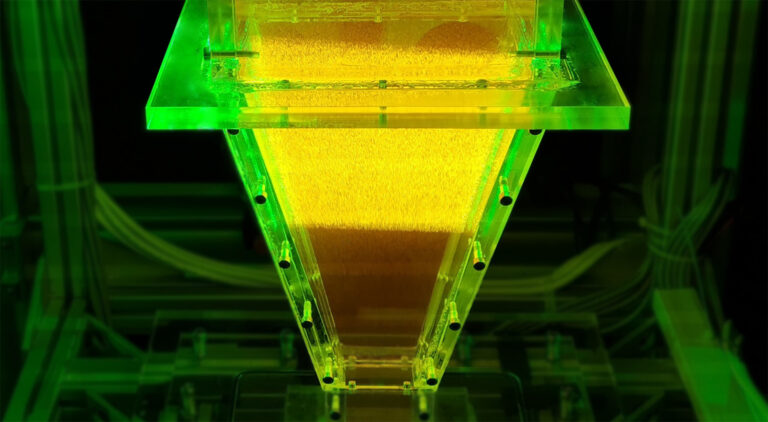

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering