Mechanical Engineering

Mixing up helps stop engine super-knock

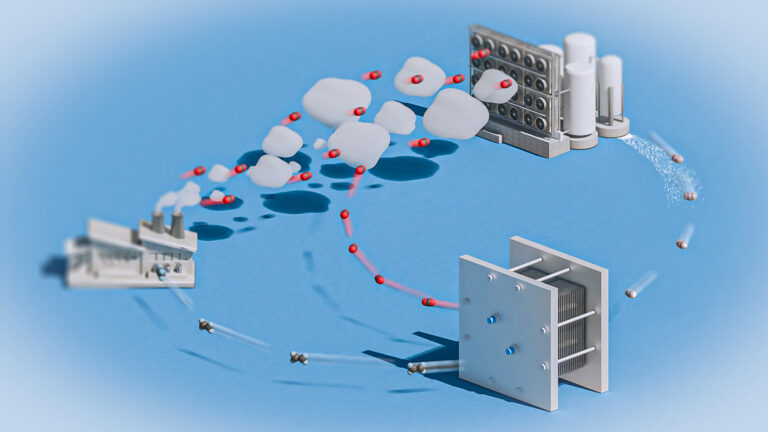

Predictions reveal how pressure and temperature fluctuations in engine cylinders can suppress damaging fuel combustion events.

KAUST researchers are using predictions to reveal how pressure and temperature fluctuations in engine cylinders can suppress damaging fuel combustion events. © 2020 KAUST

A method to predict and avoid undesirable combustion events in advanced engines, such as knocking and super-knock, implicates the initial mix of fuel and air.

Next-generation engines could exploit advanced combustion modes to squeeze significantly more mileage from each drop of fuel, while simultaneously lowering harmful emissions. But the high-pressure, low-temperature conditions these advanced engines operate under leave them more vulnerable to engine-damaging abnormal fuel combustion events.

“Downsized, boosted engines with higher thermal efficiency and cleaner combustion processes that reduce CO2 emissions as well as NOx and soot is a major development trend for advanced engines,” says Minh Bau Luong, a postdoc in the research group of Hong Im at the Clean Combustion Research Center, who led the research. Finding ways to overcome the higher propensity of these engines for abnormal combustion events, including super-knock, a detonation event generating extreme, damaging pressure oscillations, was the aim of the team’s latest research.

“The key hypothesis of this study was that the occurrence of engine knock is determined by the way the composition and temperature of the fuel/air mixture is distributed at the onset of ignition,” Im explains.

In previous work, Im had developed a theoretical formula to predict fuel ignition behavior based on a metric called the Sankaran (Sa) number, which relates flame speed and propagation to the temperature gradient. “The significance of the Sa-based metric is that the prediction of combustion modes is based purely on the initial conditions,” Luong says.

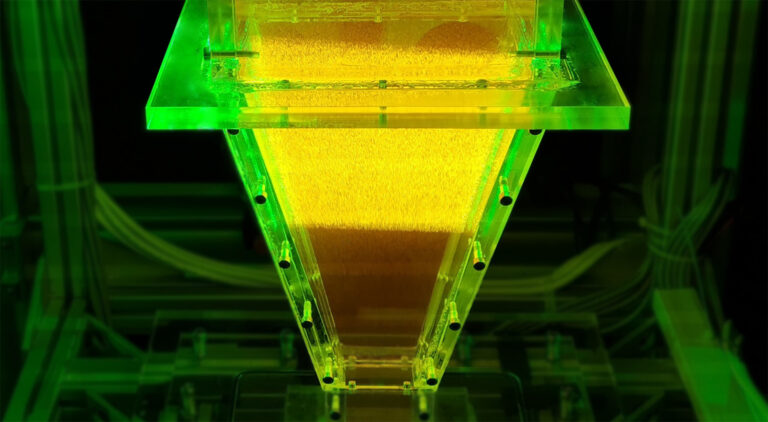

Quantitative visualization of pressure contours to depict different knock intensities (l-r): normal autoignition process, mild-knock and super-knock.

© 2020 KAUST

In their latest work, the team has extended the theoretical formula to consider temperature and concentration fluctuations of the fuel/air mixture. “Using this formula, we first predicted knock occurrence and its strength based on the mixture distribution at the onset, and then we ran direct numerical simulations to check if the prediction was right. The simulations confirmed the team’s initial hypothesis, proving that the conditions at the onset of ignition determine the occurrence and strength of engine knock events.

The study suggests that knock events would be suppressed if there were temperature and concentration fluctuations of the fuel/air mixture within the engine cylinder. “Thermal and compositional stratifications of the in-cylinder fuel/air mixture can provide a smooth, sequential combustion process under high-load conditions,” Luong says.

“To translate the knowledge gained from the study into practice, the next step is to modify the ignition criteria to determine knock probability based on the information available in larger, ‘device scale’ simulations, or experimental measurements from engines,” says Im.

References

- Luong, M.B., Hernández Pérez, F.E. & Im, H.G. Prediction of ignition modes of NTC-fuel/air mixtures with temperature and concentration fluctuations. Combustion and Flame 213, 382 (2020).| article

You might also like

Mechanical Engineering

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering

Turbulent flow shows surprise patterns that could help boost efficiency

Mechanical Engineering