Chemistry

Sensing the pressure

Thin flakes of silver make robust and flexible electrodes for pressure sensors.

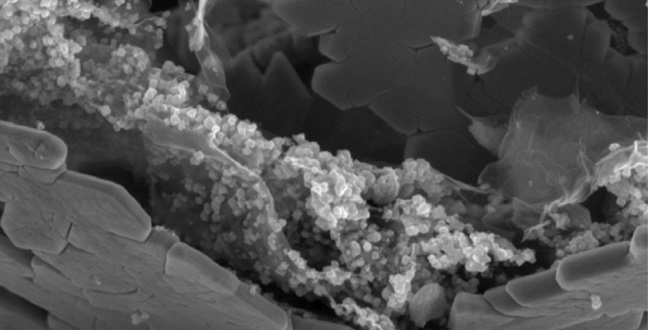

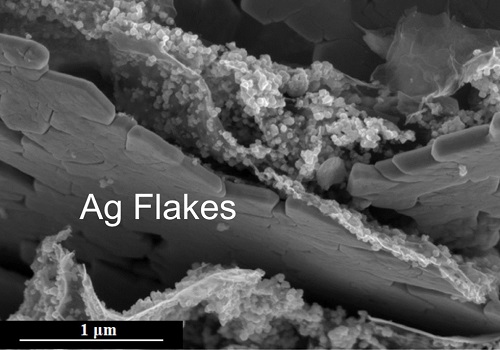

Silver microflakes suitable for flexible electrodes are grown using a simple chemical method.

Reproduced with permission from reference 1 © 2016 WILEY-VCH Verlag.

A simple chemical method for synthesizing silver microflakes for electronic applications such as pressure sensors has been developed by researchers at KAUST.

In a two-dimensional material, electrons have restricted movement, giving the material a wide range of enhanced properties relative to its three-dimensional counterpart. When producing flexible sensors, two essential properties are a broad electrical conductance and great strength.

The most well-studied two-dimensional material is a single layer of layer of carbon atoms known as graphene. This material can be created simply by peeling the top layer of atoms from a three-dimensional form of carbon known as graphite. This mechanical exfoliation technique can also be applied to materials with a graphite-like atomic structure, but other two-dimensional materials require a more complicated technique.

Niveen Khashab and her colleagues from the KAUST Advanced Membranes & Porous Materials Center have developed a chemical method for fabricating two-dimensional single-crystal silver microflakes on graphene oxide1.

They heated graphene oxide in a liquid organic compound called N-methyl-2-pyrrilidone at 180 degrees Celsius to form two-dimensional layers. They then added silver nitrate to the cooled solution and heated it again to 110 degrees Celsius. Silver atoms slowly attached themselves to the graphene oxide.

“The silver first formed nanoparticles,” Khashab said. “These provided the nucleation sites to further assemble silver atoms in order to finally form microflakes.”

The team confirmed that the flakes were single crystals using X-ray diffraction.

A crucial consideration for such methods is the ability to create large samples. Khashab and her colleagues were able to synthesize silver microflakes with a thickness of 100 nanometers as large as 10 micrometers. The samples had a low electrical resistance and they were flexible enough to be folded.

The team demonstrated the utility of their material for electronic applications by incorporating it in to a pressure sensor. They placed two graphene oxide/silver microflakes 20 micrometers apart within a compressible material called styrene-isoprene-styrene. When it was pressed, the two microflakes drew closer together and this changed the electrical charge stored between them. This change could be detected using an external circuit.

“By attaching our device to a person’s knee, we could distinguish between knee bending, squatting and walking,” Khashab explained. The structure was also sensitive enough to detect the light touch of a fingertip.

Also important is that the device was robust and reliable with little change in electrical characteristics after 10,000 compression cycles, noted Khashab.

References

- Chen, Y. Tao, J., Hammami, M. A., Hoang, P. & Khashab N. M. Self-assembly of single-crystal silver microflakes on reduced graphene oxide and their use in ultrasensitive sensors. Advanced Materials Interfaces 3, 1500658 (2016).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

Natural polymer boosts solar cells

Chemistry

Disruptive smart materials flex with real world potential

Chemistry

Catalysts provide the right pathway to green energy

Chemistry

Hollow molecules offer sustainable hydrocarbon separation

Chemistry

Maximizing methane

Chemistry

Beating the dark current for safer X-ray imaging

Chemical Engineering