Chemistry | Computer Science | Material Science and Engineering

Scintillating new X-ray imaging

Less hazardous and more sensitive and eco-friendly scintillating compounds could greatly improve X-ray imaging technologies.

A multidisciplinary KAUST team is developing novel scintillation materials for X-ray imaging applications. These materials light up, or “scintillate,” in response to X-rays that have passed through them. The patterns of light from the scintillation screens create the images that reveal the desired details of the sample being examined.

Researchers worldwide are continually seeking new scintillators that will provide greater sensitivity at lower cost and with simpler fabrication methods. Some of the most promising alternatives have been compounds containing lead that are not only toxic, but have stability problems that limit their commercial potential. Postdoc Hong Wang, Ph.D. candidate Tengyue He and colleagues in Omar Mohammed’s research group are now exploring the potential of chemically stable lead-free materials that are nontoxic and readily processed.

“We were surprised to find that compounds called organocopper halides have excellent X-ray responses, including high light yield and low detection limit,” says Wang. “We didn’t believe this result until we checked it many times.”

Wang adds that it was a significant technical challenge to incorporate the new materials into uniform scintillator screens. The team went through a lengthy process of exploring methods to optimize the preparation techniques. They finally managed to combine their halides with an organic polymer to achieve an X-ray imaging screen with an exceptional scintillation level[1]. “It has one of the highest values so far reported for scintillation materials based on organic metal halides,” Wang says.

In related work, also led by Mohammed, He and colleagues have developed other copper-based halide scintillating compounds[2]. They fabricated two types of their scintillators into nanorods and nanoparticles. These materials also exhibited ultrahigh yields and very impressive spatial imaging resolution.

The imaging resolution of the screens based on these innovations is 150 percent higher than that of currently available commercial systems, as well as having much improved homogeneity relative to screens made with other polymer/powder mixtures.

The team is also achieving detection of X-rays at ultralow levels, between 55 and 92 times lower than the current levels needed for standard medical X-ray examinations. This could significantly reduce exposure to X-rays and the risks to patients if the new scintillators could become incorporated into standard commercial technology.

The low toxicity of the lead-free compounds would also reduce the hazards faced by the workers producing the screens and the operators working with them.

“I was truly exhilarated to witness that the imaging resolution and homogeneity of the screens could reach such a high level,” says He.

The key physical improvement behind the increasing performance achieved by the compounds developed by the researchers appears to be at least partly based on moving the size of the scintillating particles down from the micrometer to the nanometer scale.

Moreover, all of the scintillators display very low levels of scattering of incident X-rays and self-absorption of energy: two problems that have hindered earlier attempts to develop useful new scintillators.

The researchers are now moving towards exploring the commercial potential of their discoveries. He, for example, hopes to help demonstrate the potential for nondestructive testing applications in which the transmission of X-rays through a material can assess the integrity of its fabrication and check for any flaws.

Wang hopes to tackle the challenge of making larger area screens of sizes more suitable for real-world applications.

“These ground-breaking innovations with outstanding image resolution and brightness have the potential to revolutionize medical, industrial and security applications, while overcoming limitations and challenges faced by earlier attempts,” says Mohammed. “Based on these findings, we believe that the future of X-ray technology appears brighter and more promising.”

Reference

- Wang, H., Wang, J-X., Song, X., He, T., Zhou, Y., Shekhah, O., Gutierrez-Arzaluz, L., Bayindir, M., Eddaoudi, M., Bakr, O. M. & Mohammed, O. F. Copper organometallic iodide arrays for efficient X-ray imaging. ACS Central Science 9, 668-674 (2023).| article

- He, T., Zhou, Y., Yuan, P., Yin, J., Gutierrez-Arzaluz, L., Chen, S., Wang, J-X., Thomas, S., Alshareef, H. N., Bakr, O. M. & Mohammed, O.F. Copper iodide inks for high-resolution X-ray imaging screens. ACS Energy Letters 8, 1362-1370 (2023).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

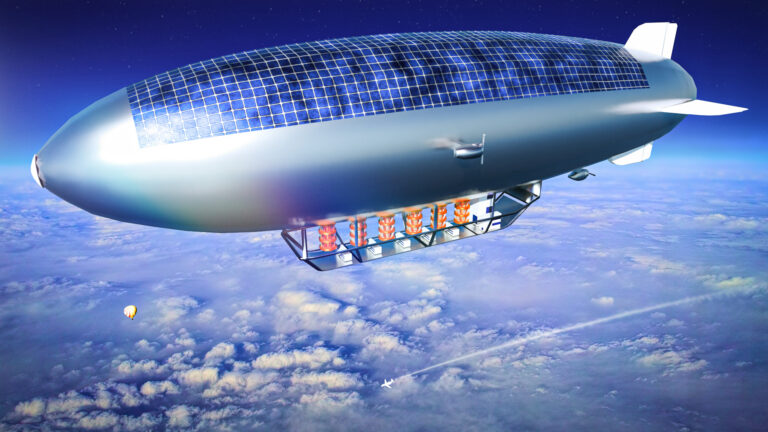

Green quantum computing takes to the skies

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Computer Science

Probing the internet’s hidden middleboxes

Applied Physics