Chemistry

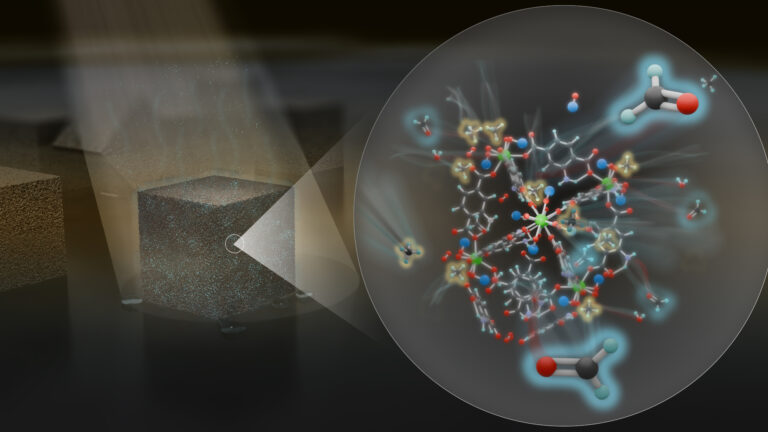

Lining MOF pockets to detect noxious gases

Custom-made gas-sensing material could lead to inexpensive devices for real-time air-quality analysis.

A porous material with tailor-made pockets stitched into its structure is a promising material for sensing noxious gases. A thin film of the material, coated onto an electrode, formed an electronic sensor that could detect traces of sulfur dioxide gas1. The sensor is a significant step toward real-world devices that can sniff out dangerous gases in real air.

Although several lab-based analytical instruments can detect traces of a specific gas in the air, these instruments are typically large, expensive, power-hungry machines. There is still a need for small, inexpensive, energy-efficient sensors that, for example, could be widely deployed around industrial sites to continually monitor air quality.

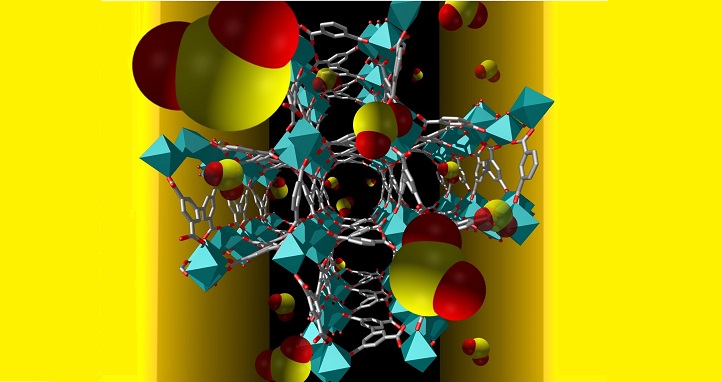

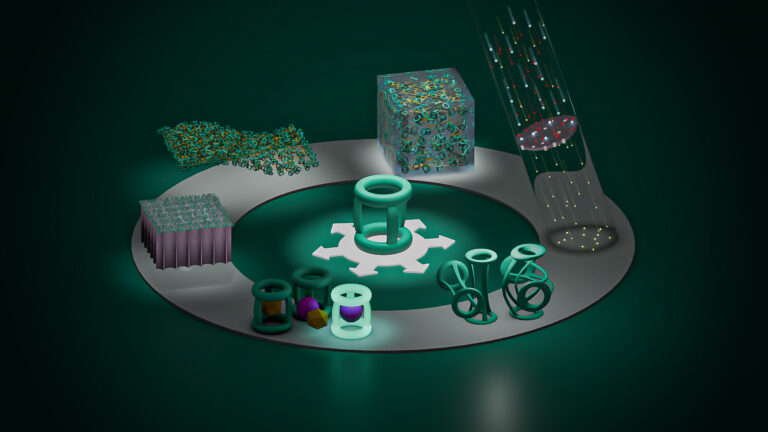

One promising way to make such sensors involves porous materials called metal-organic frameworks (MOFs). By making the MOF from different metal atoms and organic linkers, researchers can create materials that selectively absorb specific gases into tailor-made pockets within the structure. Two KAUST research groups, led by materials scientist Mohamed Eddaoudi and electrical engineer Khaled Salama, recently teamed up to develop MOF-based gas sensors.

The first step was completed in 2015 when the team made a proof-of-concept sensor by coating a MOF layer onto an electrode2. The device senses gases in a similar way that a touchscreen senses a finger. The gas changes the MOF sensor’s capacitance, an electronic property that can be directly measured using the electrode.

Now, the team is working toward specific applications. “Our current work aims to identify the ideal MOF, in terms of sensitivity and selectivity, for detection of sulfur dioxide,” says Valeriya Chernikova, a Ph.D. student from Eddaoudi’s lab.

The researchers selected an indium-based version of a MOF called MFM-300 as their sensor material. A thin film of the material could be grown onto the electrode under mild conditions that do not damage the sensor circuit. The resulting material forms pockets lined with two -OH groups and four C-H groups that selectively bind sulfur-dioxide molecules. In lab tests using simple mixtures of gases, the sensor could detect sulfur dioxide at concentrations of just a few parts per billion.

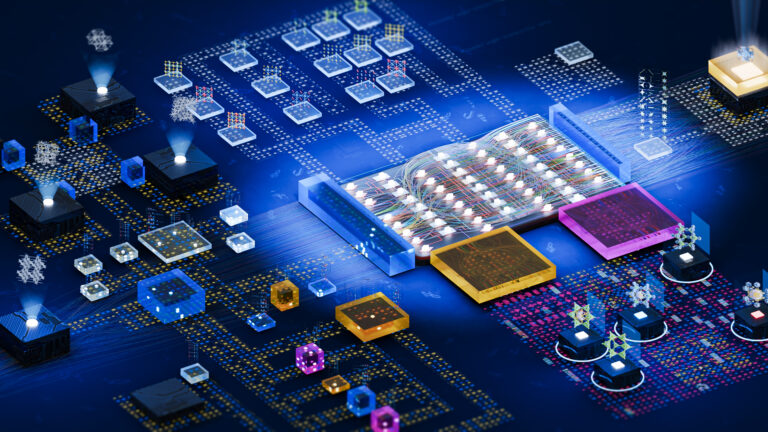

To use the technology for real air—which comprises a much more complex mixture of gases—the next step is to develop sensor arrays that pool the responses of multiple MOF materials, Chernikova says. “The data will be processed using various statistical and machine learning algorithms to improve the accuracy of the sensor’s response,” she continues. “This is commonly referred to as an ‘artificial nose’.”

References

-

1. Chernikova, V., Yassine, O., Shekhah, O., Eddaoudi, M. & Salama, K. N. Highly sensitive and selective SO2 MOF sensor: the integration of MFM-300 MOF as a sensitive layer on a capacitive interdigitated electrode. Journal of Materials Chemistry 6, 5550–5554 (2018).| article

- Sapsanis, C., Omran, H., Chernikova, V., Shekhah, O., Belmabkhout, Y., Buttner, U,. Eddaoudi, M. & Salama, K.N. Insights on Capacitive Interdigitated Electrodes Coated with MOF Thin Films: Humidity and VOCs Sensing as a Case Study. Sensors 15, 18153-18166 (2015).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

Natural polymer boosts solar cells

Chemistry

Disruptive smart materials flex with real world potential

Chemistry

Catalysts provide the right pathway to green energy

Chemistry

Hollow molecules offer sustainable hydrocarbon separation

Chemistry

Maximizing methane

Chemistry

Beating the dark current for safer X-ray imaging

Chemical Engineering