Chemistry

Pure clear polymers

A clean, green, metal-free approach to making high-performance polycarbonates.

KAUST researchers have developed a greener way to make the common polymer used in CDs and many other applications.

© 2016 Alamy BNKGCW

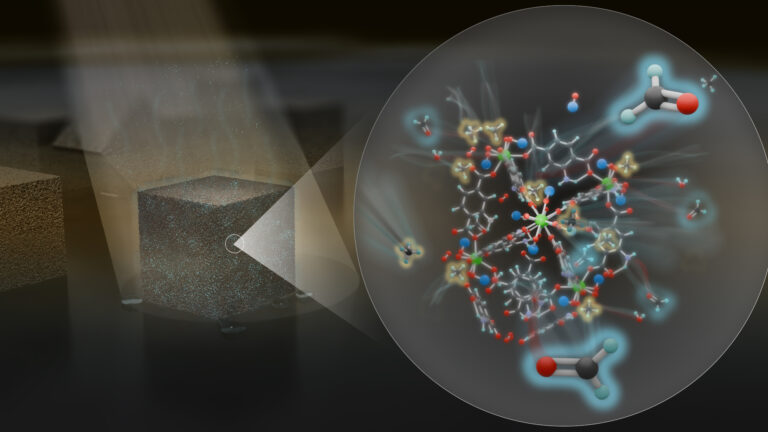

From the transparent cockpit canopy of fighter jets to everyday applications such as spectacle lenses and Blu-ray discs, polycarbonate plastics are valued for being light, strong and offering exceptional optical clarity. KAUST researchers have discovered a simple, clean, metal-free way to make polycarbonates from CO2.

One of the more environmentally friendly ways to make polycarbonates is to use carbon dioxide as one of the component monomers, making good use of what is otherwise an unwanted greenhouse gas. However, to make polycarbonates this way, manufacturers must currently use complex organometallic catalysts, which are difficult to make and which leave metal residues in the finished plastic. Not only can these metals be toxic, but they also discolor the polymer with a yellow taint that requires extra purification steps to remove.

Instead of an organometallic catalyst, Nikos Hadjichristidis and Yves Gnanou and colleagues from the University’s Physical Science and Engineering Division developed a purely organic catalyst system that is highly effective, simple to use and requires no additional purification steps.

To make polycarbonates from CO2, the gas is mixed with a partner monomer called an epoxide.

“Common wisdom told us that to produce linear polycarbonate chains from the copolymerization of CO2 with epoxides, there is no option but to resort to organometallic complexes,” said Gnanou.

The organometallic catalyst’s role is to capture epoxide molecules from the mixture and attach them to the growing polymer chain. Without the organometallic catalyst, the sluggish epoxide addition step meant the growing chains would often react with their own tails instead, forming cyclic structures rather than the desired long-chain polymer.

“In polymerizations that are crippled by side reactions such as cyclizations, one classical way to foster the formation of linear chains is to activate the monomer,” Gnanou explained, which is what the researchers did.

In place of the organometallic catalyst, the team used a pair of reaction initiators: an ammonium compound to capture and activate the CO2 and an electron-poor boron-based compound to activate the epoxide. This combination coupled the two monomers just as effectively as many organometallic catalysts.

“The polycarbonates samples we obtained are not at all colored, and the activator used can be easily removed by washing the sample with water,” Gnanou said.

The team believes that their approach could be used to make a wide range of polymers, Gnanou added. “The next step would be to apply the same concept to other epoxides and more generally to other related monomers,” he said.

References

-

Zhang, D., Boopathi, S.K., Hadjichristidis, N., Gnanou, Y. & Feng, X. Metal-free alternating copolymerization of CO2 with epoxides: Fulfilling “green” synthesis and activity. Journal of the American Chemical Society 138, 11117 (2016).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

Natural polymer boosts solar cells

Chemistry

Disruptive smart materials flex with real world potential

Chemistry

Catalysts provide the right pathway to green energy

Chemistry

Hollow molecules offer sustainable hydrocarbon separation

Chemistry

Maximizing methane

Chemistry

Beating the dark current for safer X-ray imaging

Chemical Engineering