Chemistry

Membrane offers an efficient way to purify gas mixtures

Porous nanosheets combined with polymers can remove contaminants from methane.

A team of KAUST scientists has devised an energy efficient way of removing unwanted contaminants from natural gas. © 2022 KAUST. /en/article/1251/membrane-offers-an-efficient-way-to-purify-gas-mixtures

A team of KAUST scientists has devised an energy efficient way of removing unwanted contaminants from natural gas. © 2022 KAUST. /en/article/1251/membrane-offers-an-efficient-way-to-purify-gas-mixtures

Natural gas is the world’s main source of methane, widely used as a fuel and a chemical feedstock, but it often contains unwanted gases such as hydrogen sulfide and carbon dioxide. KAUST researchers have now developed a membrane that can remove these contaminants in a much more energy-efficient way than conventional processes that rely on chemical washes.

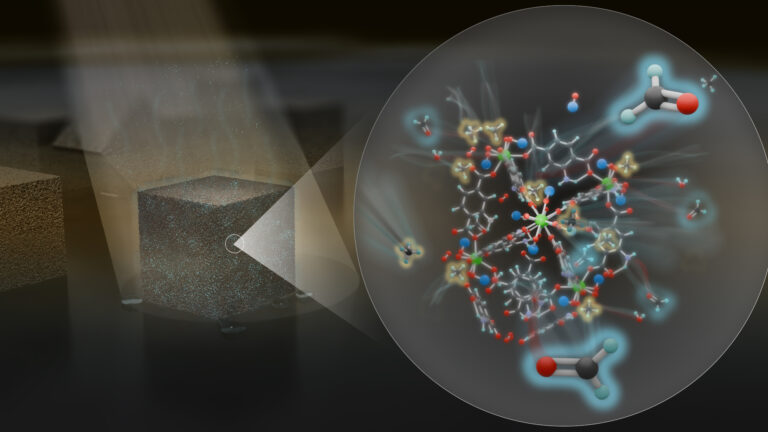

The membrane is based on a crystalline metal-organic framework (MOF) material. MOFs contain pores that can be tailored to allow certain gas molecules to pass through while blocking others. In principle, MOFs could be used with flexible, robust polymers to produce practical separation membranes, but until now it has been difficult to unite the materials without curtailing their desirable properties.

To solve this problem, the KAUST team developed a new three-part strategy to bring a MOF and a polymer together into a mixed-matrix metal-organic framework (MMMOF) membrane. First, the researchers identified a MOF, called KAUST-8, whose pores form tiny channels that are large enough to fit molecules of hydrogen sulfide and carbon dioxide but not methane.

The MOF’s pores form tiny channels that are aligned in one direction through the crystal. The researchers carefully grew their MOFs into flat nanosheets, so that the channels ran from one face of the sheet to the other.

Finally, the researchers sandwiched thousands of these nanosheets between layers of a robust polyimide polymer. The nanosheets were oriented so that their channels all lay in the same direction. This ensured that contaminant gases could easily pass through multiple nanosheets and travel from one side of the 50-70 micrometer-wide membrane to the other.

The researchers tested the membrane with different gas mixtures that simulated raw natural gas compositions in Saudi Arabia and other countries. “In all compositions, our membrane demonstrated far better separation than other reported membranes,” says first author Shuvo J. Datta, a member of the team.

For example, the team ran a 30-day test to purify methane contaminated with 1 percent hydrogen sulfide and 9 percent carbon dioxide. Under mild temperature and pressure conditions, the gas collected on the other side of the membrane contained 6 percent hydrogen sulfide and 85 percent carbon dioxide, indicating a very high selectivity for the contaminants. The membrane could also separate other mixtures of industrial gases, such as hydrogen and nitrogen.

“This method is remarkably energy efficient,” says Mohamed Eddaoudi, who led the team. “We want to scale up the procedure to demonstrate its commercial potential.”

References

- Datta, S.J., Mayoral, A., Bettahalli, N.M.S., Bhatt, P.M., Karunakaran, M., Carja, I.D., Fan, D., Mileo, P.G.M., Semino, R., Maurin, G., Terasaki, O. & Eddaoudi, M. Rational design of mixed-matrix metal-organic framework membranes for molecular separations. Science 376, 1080-1087 (2022).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

Natural polymer boosts solar cells

Chemistry

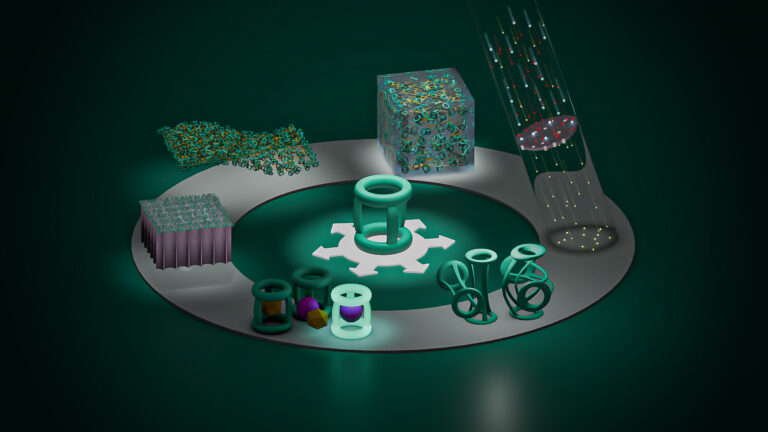

Disruptive smart materials flex with real world potential

Chemistry

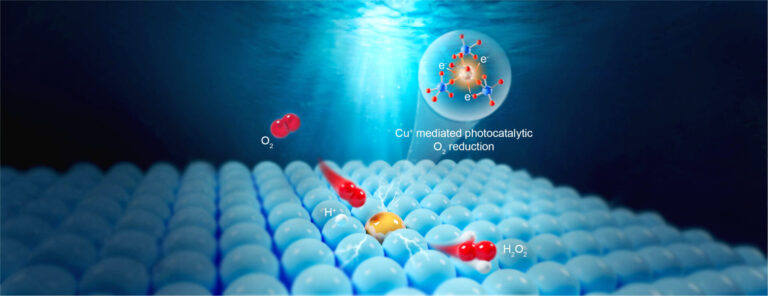

Catalysts provide the right pathway to green energy

Chemistry

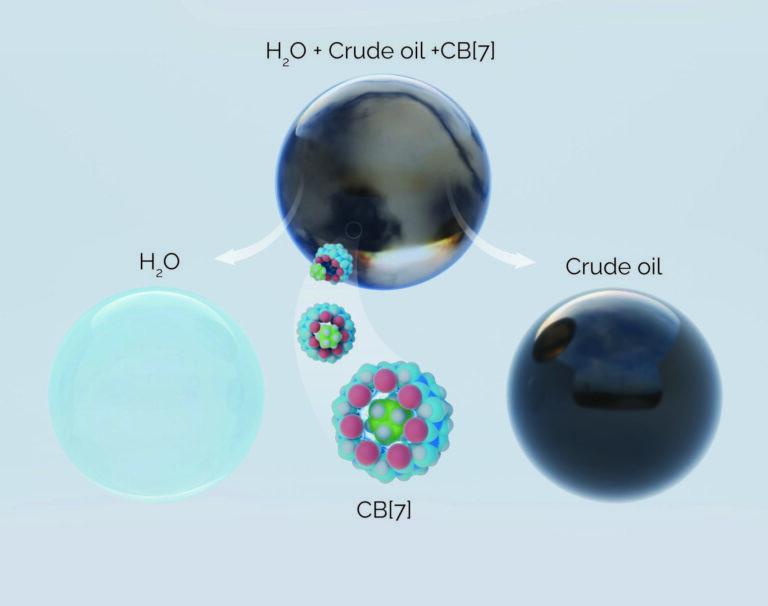

Hollow molecules offer sustainable hydrocarbon separation

Chemistry

Maximizing methane

Chemistry

Beating the dark current for safer X-ray imaging

Chemical Engineering