Chemistry

A cool chemical separation technology

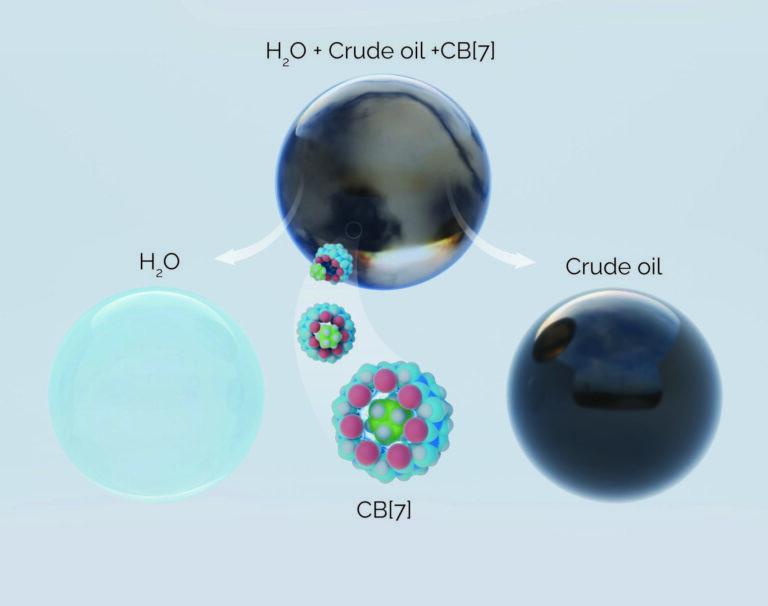

A diverse category of porous materials can separate and purify key industrial chemicals at low temperatures.

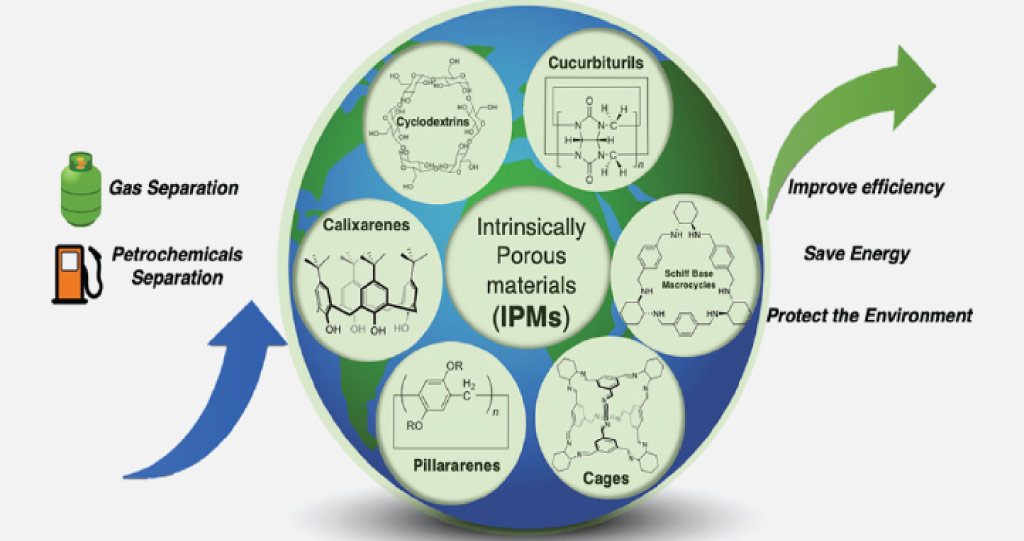

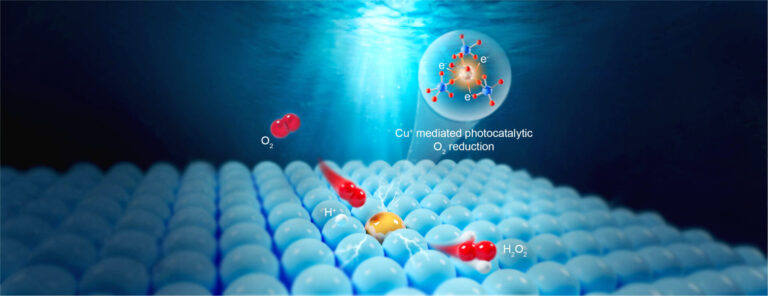

Gas and liquid separation processes in the chemical industry could be made more efficient and environmentally friendly by using substances known as intrinsically porous materials (IPMs). KAUST researchers review the prospects for IPMs in the journal Accounts of Chemical Research.

Niveen Khashab and her team are currently heavily involved in IPM research. “We focus on making materials that will have an impact on the chemical and petrochemical industries in Saudi Arabia and the world,” says Niveen Khashab, the corresponding author of the review.

IPM materials can separate gases and liquids without using traditional high-temperature methods like heat-driven distillation.

IPMs can be used to separate liquids and gases in a more efficient and environmentally friendly way by avoiding energy-intensive methods such as heat-driven distillation.

Reprinted with permission from Zhang et al. 2021. Copyright 2021 American Chemical Society.

“Through the review, we identified some IPMs with impressive performance,” says Gengwu Zhang, a postdoc in Niveen Khashab’s team. He explains that these IPMs, like other porous materials being developed, could save 70 to 90 percent of the energy costs of existing technologies, with consequent environmental advantages.

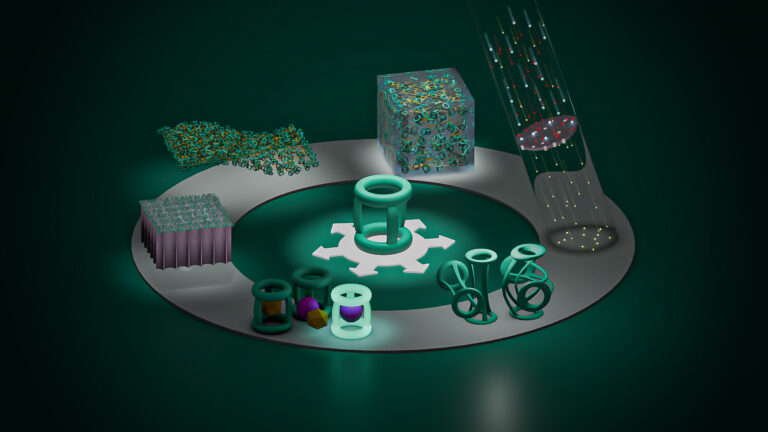

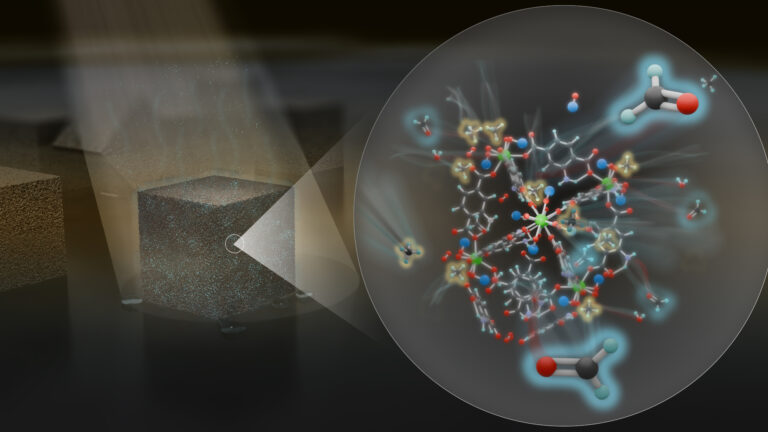

A key advantage of IPMs over many other porous materials is their stability and ability to maintain their porous properties in the solid, liquid, gas or solution states. They can also be readily processed and modified when in solution, unlike many alternatives.

“They can be easily prepared on a large scale by using cheap starting materials,” says Zhang, “Some of them are even commercially available products.”

IPMs have diverse chemical structures, but they share the property of being permeated with pores that have sizes and chemical natures that make them suitable for separating and purifying different molecules. The structure of the pores determines which chemicals they can selectively adsorb, block or allow to pass through.

The KAUST authors reviewed the state of research into several IPMs, ranging from large individual molecules with internal pores to giant assemblies of molecules held together by weak multimolecular interactions.

The most promising IPMs identified in the review include the chemicals cyclodextrin, cucurbiturils, pillararenes, trianglamines and porous organic cages (POCs). These are all carbon-based or “organic” compounds. Cyclodextrins are ring-like carbohydrate structures produced from natural starch. The other compounds are specialized products of synthetic organic chemistry. The potential of these materials has been demonstrated by their performance in separating common industrial gases and liquid derivatives of the central industrial chemical benzene.

Khashab explains that the KAUST team are now addressing the challenge of scaling up their own work on IPMs, saying: “We have started discussions with Aramco for a pilot plan for liquid separations that should begin this year.”

References

- Zhang, G., Hua, B., Dey, A., Ghosh, M., Moosa, B.A. & Khashab, N.M. Intrinsically porous molecular materials (IPMs) for natural gas and benzene derivatives separations. Accounts of Chemical Research 54, 155–168 (2021).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

Natural polymer boosts solar cells

Chemistry

Disruptive smart materials flex with real world potential

Chemistry

Catalysts provide the right pathway to green energy

Chemistry

Hollow molecules offer sustainable hydrocarbon separation

Chemistry

Maximizing methane

Chemistry

Beating the dark current for safer X-ray imaging

Chemical Engineering