Mechanical Engineering

Turbocharging the switch to efficient engines

Predicting capricious pre-ignition combustion events could enable automakers to build powerful yet more efficient engines.

A combustion problem that has troubled engine manufacturers since the industry began still plagues the designers of fuel-efficient engines. A team at KAUST’s Clean Combustion Research Center, led by Robert Dibble, focuses on understanding pre-ignition.

A single occurrence of pre-ignition—when fuel ignites prematurely in the engine cylinder to release a mistimed kick of energy—can cause major damage. Pre-ignition is sporadic and unpredictable. It is more prevalent in the downsized, turbocharged engines that car makers are now producing for improved fuel efficiency while maintaining power output.

“Pre-ignition remains a bottleneck to further downsizing and improving engine efficiency,” explains Eshan Singh, a Ph.D. student in Dibble’s team.

The team systematically changed engine parameters, including air intake temperature and exhaust back-pressure, thereby establishing the conditions most likely for pre-ignition. For example, the team observed more pre-ignition events with a higher exhaust back pressure: this occurs when the emptying of burnt fuel by the engine cylinder between combustion cycles is ineffective.

The researchers combined all their observations to build a picture of the pre-ignition phenomenon. “Our work unravels that the pre-ignition event is divided into several steps,” Singh says.

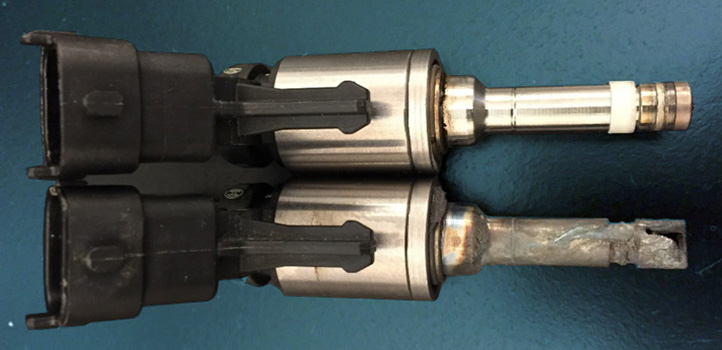

A pre-ignition event originates during the previous fuel combustion cycle, when fuel injected into the cylinder interacts with oil on the cylinder liner forming an oil-fuel droplet. At the end of each combustion cycle, the oil-fuel droplet is usually expelled from the cylinder; however, from time to time, the oil-fuel droplet remains and may trigger pre-ignition in the following cycle, the team showed. “Car makers need to break this chain of events to suppress pre-ignition,” Singh says.

Ph.D. student Eshan Singh working on the KAUST pre-ignition engine.

© 2019 Raheena Abdurehim

Stopping the fuel and oil from interacting, or completely exhausting all the burnt mixture from the engine, are two points where the event chain can be broken. Preventing the injected fuel from hitting the oil-coated cylinder liner is one approach. “We are looking at practical methods to reduce pre-ignition by changing the injection strategy,” Singh says. “We have filed a patent that uses injection strategies to provide pre-ignition-free operation without compromising engine power.”

Other routes to break the chain of events demand deeper understanding of pre-ignition, Singh adds. “Our exciting discoveries are gratifying. Going forward, we are motivated to uncover additional controlling variables that allow for more accurate pre-ignition predictions.”

Due to graduate from KAUST in the fall of 2019, Eshan is currently interning at the Combustion Research Facility in Sandia National Laboratories, California. There he is exploring mixed-mode combustion for future internal combustion engines. “This experience has already exposed me to a plethora of tools that are frequently used in engine combustion diagnostics. Several new avenues have now opened for my research career, which is vested in tackling solutions to combat climate change.”

References

-

Singh, E. & Dibble, R., Mechanism triggering pre-ignition in turbo-charged engines. SAE Technical Paper No. 2019-01-0255 (2019).| article

You might also like

Mechanical Engineering

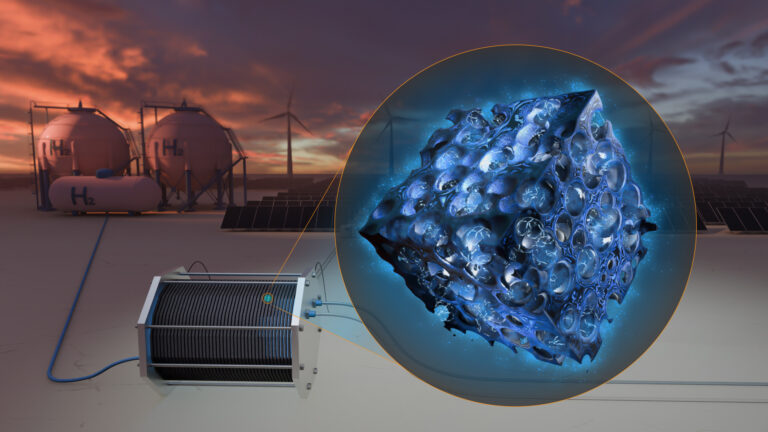

Green hydrogen from fluctuating power sources

Mechanical Engineering

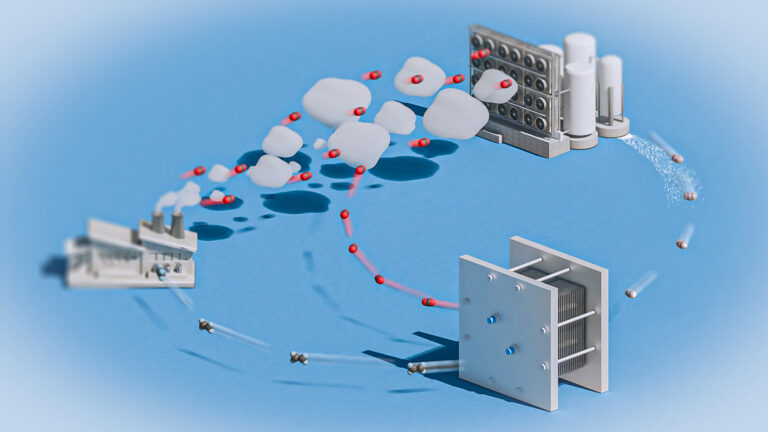

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

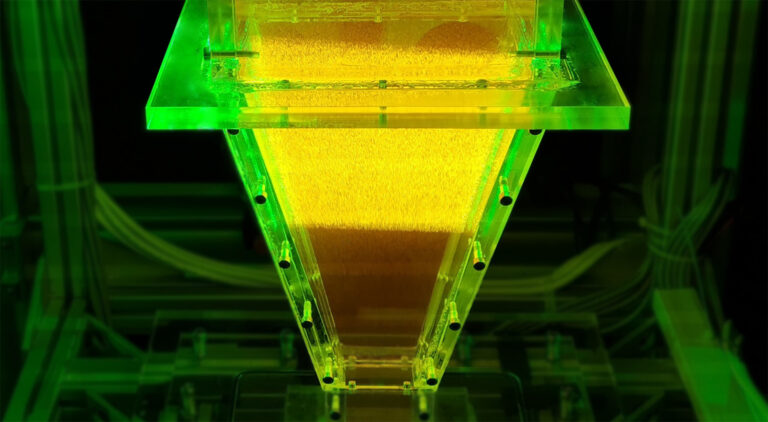

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering