Material Science and Engineering

Thin films for more efficient solar cells

Tantalum nitride as thin layers improves the extraction of electrons from silicon solar cells.

The efficiency of solar cells can be increased by thin-film contacts developed by researchers at KAUST.

Improving the performance of solar cells requires scrutinizing every aspect of their design. First, this means improving the crystalline quality of the absorbing material to maximize the conversion of photons to negatively charged electrons and positively charged holes. Next, the device’s architecture must be optimized to ensure that these charge carriers can move efficiently through the material. Finally, the electrical contacts that extract the carriers from the device and into an external circuit need to be perfected.

Xinbo Yang and his colleagues from the KAUST Solar Center and the KAUST Core Labs, together with coworkers from the Australian National University, focus on this third step by developing electron-selective tantalum-nitride thin-film contacts for silicon solar cells.

The interface between a silicon and a metal contact can create a high-resistance barrier that disrupts current flow. Additionally, the metal-induced electronic states at the surface of silicon enable the charge carrier to recombine, which reduces the conversion efficiency. Traditionally, high-cost processes, such as diffusion and chemical-vapor deposition of additional layers were adopted to reduce the contact resistance and carrier recombination.

Yang and the team combat these problems by placing tantalum nitride on silicon using a method known as atomic-layer deposition: they do this by exposing the surface to a gas, causing a high-quality thin film to build up one atom at a time.

“Electron-selective tantalum-nitride contacts can simultaneously reduce the charge carrier recombination and contact resistance,” explains Yang. “This can simplify the complexity of fabricating the device and lower the production cost.”

By experimentally investigating the electrical properties of the tantalum nitride–silicon interface, the researchers showed that the tantalum nitride interlayer was able to reduce the contact resistance to the flow of electrons from silicon and metal contacts made of silver or aluminum. But, it simultaneously blocked the flow of holes, reducing the carrier recombination

A silicon solar cell that uses an electron-selective tantalum-nitride-metal contact for improved efficiency.

© 2018 KAUST

The team created a silicon solar cell that used an electron-selective tantalum-nitride-metal contact. They showed that this improved the power conversion efficiency—the ratio between electrical power out to optical power in—by more than 20 percent over a control device built without the tantalum nitride. They also found that it simplified the device fabrication sequence and reduced costs by eliminating doping and contact opening processes.

“We are also investigating the potential application of tantalum nitride electron transport layers for organic and perovskite solar cells,” explain KAUST scientist and principal investigator, Stefaan De Wolf.

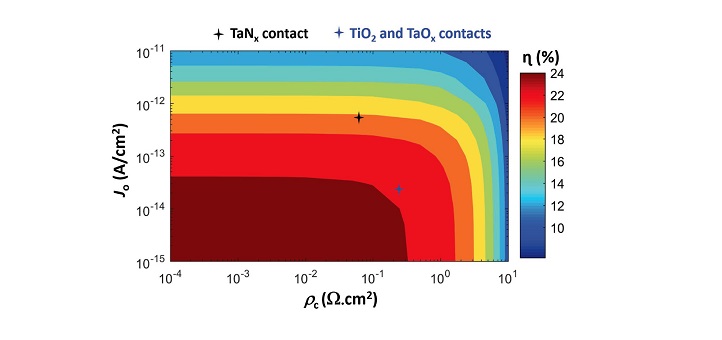

The dependence of cell efficiency on the recombination current density (Jo) and the contact resistivity (ρc) of the full-area rear contact.

Reproduced with permission from reference 1 © 2018, John Wiley and Sons.

References

- Yang, X., Aydin, E., Xu, H., Kang, J., Hedhili, M., Liu, W., Wan, Y., Peng, J., Samundsett, C., Cuevas, A. & De Wolf, S. Tantalum nitride electron-selective contact for crystalline silicon solar cells. Advanced Energy Materials 8, 1800608 (2018).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics