Mechanical Engineering

Biodiesel by-product helps fuel come clean

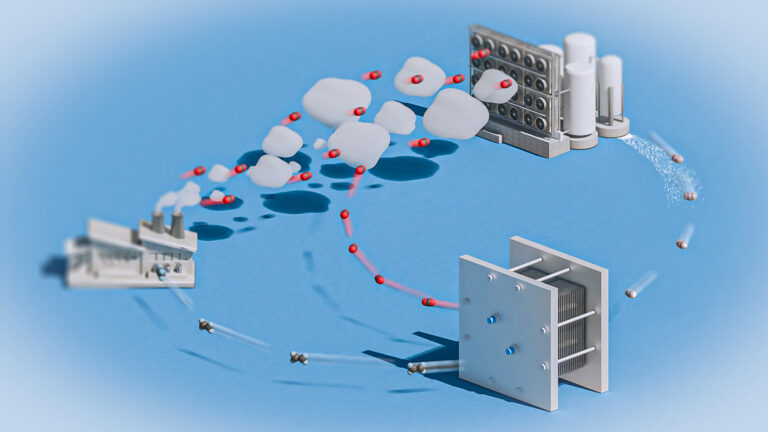

A compound made from the glycerol by-product of biodiesel production could promote cleaner burning in vehicle engines.

The potential of glycerol waste from biodiesel production to be simply converted into a clean-burning sustainable fuel is being explored by scientists at KAUST’s Clean Combustion Research Center.

“As one of the world’s leading teams in combustion research and innovation, we are always looking into new fuels and additives that help maximize engine efficiency and minimize environmental pollution,” says research scientist Binod Giri.

Concern over diminishing fossil fuel reserves and the environmental damage caused by current fuel technologies is driving interest in more sustainable and cleaner fuels. One major avenue to reduce global dependence on fossil fuels is by producing biodiesel from waste vegetable oils and animal fats. Burning glycerol carbonate generated from the excess glycerol produced by biodiesel production offers the extra advantage of greatly reducing emissions of the sooty particulates that cause respiratory disease.

This work on glycerol carbonate also supports Saudi Arabia’s Vision 2030 initiative, which aims to diversify the Kingdom’s economy from its current reliance on the oil industry.

Giri explains that this research stems from the idea that some of the hydrocarbons derived from crude oil, which contain only hydrogen and carbon, can be replaced with compounds that also contain oxygen. As well as reducing particulate emissions, burning these oxygenated compounds generates less carbon dioxide, a greenhouse gas linked to global warming.

Oxygenated compounds are known to burn with near-zero soot emissions if the oxygen content is in excess of 33 percent by mass. The oxygen content of glycerol carbonate is 59 percent. The researchers used computational analysis to explore the effect of differing pressures and temperatures on the combustion reactions. This allowed them to identify conditions in which glycerol carbonate will burn cleanly, while also generating the compound 3-hydroxypropanal, which is known to greatly reduce the production of soot.

“Our results show that glycerol carbonate has great potential to promote cleaner combustion as a fuel additive,” Giri concludes.

Investigating the chemistry of fuels under engine-relevant extreme temperatures and pressures is a significant challenge. The KAUST researchers are collaborating with Milan Szori and Bela Viskolcz at the University of Miskolc in Hungary, which “brings together two world-leading teams with the expertise to understand the complexities of combustion chemistry,” Giri explains.

Further research aims to reveal how to optimize blending glycerol carbonate with conventional fuels. “This work has the potential to change the future directions of fuel-engine research,” says Aamir Farooq who supervised this work. He and his colleagues are excited about their possible contribution to developing cleaner and greener transportation systems worldwide.

References

- Szőri, M., Giri, B. R., Wang, Z., Dawood, A. E., Viskolcz, B. & Farooq, A. Glycerol carbonate as a fuel additive for a sustainable future. Sustainable Energy & Fuels 2, 2171-2178 (2018).| article

You might also like

Mechanical Engineering

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering

Turbulent flow shows surprise patterns that could help boost efficiency

Mechanical Engineering