Chemical Engineering

Graphene oxide sifts out CO2

Graphene oxide combined with a polymer membrane creates a barrier that is selectively permeable to carbon dioxide.

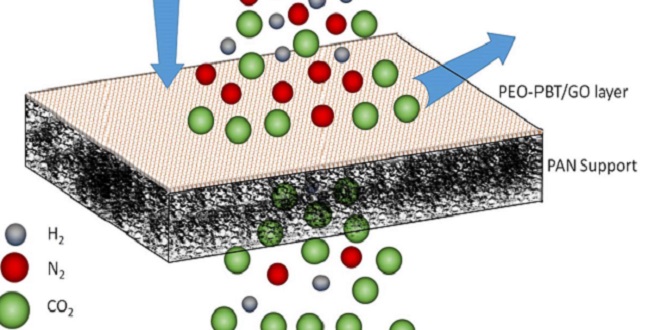

Schematic impression of the hybrid membrane (PEO-PBT/GO layer) retaining hydrogen and most nitrogen molecules while carbon dioxide molecules pass through.

© 2015 KAUST

An intensive worldwide effort to find new and more efficient ways to separate carbon dioxide (CO2) from gas streams is being driven by growing concerns about climate change.

KAUST professor Klaus-Viktor Peinemann, who has been at the forefront of this field for many years, and his research colleagues at the University have now prepared an advanced hybrid membrane that can achieve highly selective separation of CO2 with several advantages over existing CO2 capture methods.

Peinemann explained that selectively permeable membranes that either permit or restrict the passage of specific gas molecules are ideal candidate materials for use in large-scale industrial separation applications. Nine years ago, he began adapting a commercially available polymer called PolyActiveTM for gas separation procedures. PolyActiveTM contains bound polyethylene glycol groups that encourage water and CO2 to permeate a membrane while most other molecules are held back.

“In our current work at KAUST, we are improving the performance of PolyActiveTM membranes by adding small amounts of graphene oxide,” Peinemann said.

Graphene is a celebrated nano-material that is composed of a flat network of carbon atoms in hexagonal rings. It is renowned for being prepared in sheets that can be as little as one atom thick. Graphene itself is impermeable to gas molecules, but combining it with varying amounts of oxygen creates graphene oxides with selective permeabilities.

Pure graphene oxide membranes are brittle, but combining them with PolyActiveTM produces flexible membranes with permeability that can be fine-tuned by varying the size and proportions of the polymer and graphene oxide components1.

The hybrid membranes are easily prepared from dispersions of the components in water. Evaporation of excess water is the simplest of several methods available to actually form the membrane. The selective permeability of even the best membranes is not perfect, as they allow a small proportion of nitrogen to pass through, in addition to CO2. However, they are very effective for applications such as removing CO2 from industrial flue gas streams.

The simple and inexpensive method of preparation, physical flexibility and adjustable permeability of the membranes makes them ideal for further exploration of commercial possibilities.

“We will now develop our own PolyActiveTM-like polymer for preparing the membranes, and we will then seek patent protection and commercial partners,” Peinemann said.

As well as the use of the membranes for CO2 removal from flue gases, he sees potential for their use in natural gas treatment and the humidification of dry gas streams or in routine air-conditioning due to the high permeability of the membranes to water vapor.

References

- Karunakaran, M., Shevate, R., Kumar, M. & Peinemann, K-V. CO2-selective PEO-PBT (PolyActiveTM)/graphene oxide composite membranes. Chemical Communications 51, 14187–14190 (2015). | article

You might also like

Chemical Engineering

Urban air pollution goes up in smoke

Chemical Engineering

Rethinking machine learning for frontier science

Chemical Engineering

Magnetic nanoparticles capture microplastics from water

Chemical Engineering

Biogas upgrading goes with a swing

Chemical Engineering

Stronger, lighter, cheaper: a new route to carbon fiber production

Chemical Engineering

Unveiling the role of biomass-burning aerosols in atmospheric reactions

Chemical Engineering

Slashing industrial emissions using a hybrid model approach

Chemical Engineering