Material Science and Engineering

Water-treated semiconductors up transistor speed

Performance improvements of indium zinc oxide transistors could lead to enhanced transparent displays for screens and phones.

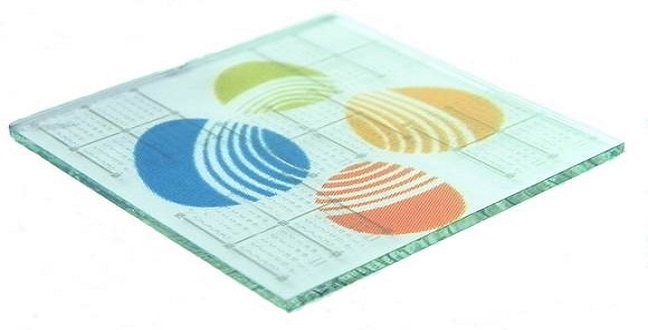

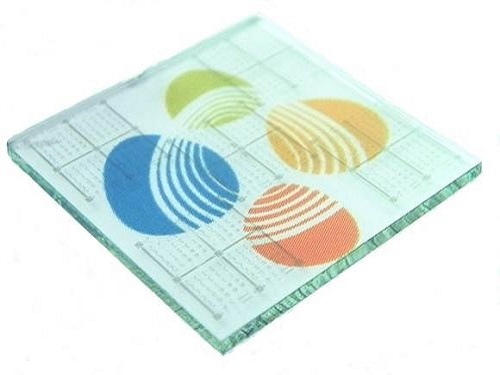

A transparent transistor for displays based on indium zinc oxide can dramatically increase performance.

© 2015 KAUST

A transistor four times faster than those currently used in high-res displays for smartphones or tablets has been developed by KAUST researchers using a simple de-ionized water treatment1.

Transparent electronics is an emerging area of research with significant potential in applications such as displays and smart windows. Transistors for display applications are used to switch display pixels on and off and so they need to be fast to enable better display resolution.

Current transistors are often made from silicon however this is limited by its lack of electron speed and transparency. Oxide semiconductors, the proposed replacements, are see-through and have greater electron mobility, enabling them to be used in displays with natural light. This eliminates the need for back light which consumes most of the display power, explains Husam Alshareef, from KAUST’s Division of Physical Science and Engineering. A popular class of materials is based on zinc oxide — which is both transparent and a good conductor of electrons — but better performance will depend on faster zinc oxide transistors.

Improvement of these transistors requires streamlining the fabrication process. One key challenge with electronic materials includes impurities such as missing oxygen atoms in the crystal structure and surface remnants from the fabrication process, typically a layer of zinc. Processes used to treat these in the silicon industry are not suitable for transparent oxide semiconductors.

The researchers from KAUST have now demonstrated that transistors made from indium-only doped zinc oxide (IZO) have a dramatic increase in performance if they undergo a simple treatment with de-ionized water prior to the final semiconductor crystallization anneal.

Treatment with de-ionized water reduces the number of missing oxygen atoms in the crystal and also leaches out some of the remaining zinc from the surface. After the treatment, the KAUST team annealed the device leaving the IZO layer itself with less zinc. IZO with lower zinc and oxygen vacancy content has higher charge carrier mobility, further improving charge transport.

In first tests the process improves the speed of electrical charges passing through the transistor by up to a factor of six. Their speed is four times higher than that of devices used in current smartphone or tablet generations. “Being a transparent oxide semiconductor IZO can also be used in other devices where transparency is needed, such as smart windows, concealed sensors, and power efficient circuits,” says Alshareef.

Pradipta Nayak, lead author of the study, adds: “We used chemical synthesis methods at low temperature, which means that these devices are compatible with flexible plastic substrates,” thereby increasing the potential applications of this technology.

References

- Nayak, P.K., Caraveo-Frescas, J.A., Wang, Z., Hedhili, M.N. & Alshareef, H.N. Six-fold mobility improvement of indium-zinc oxide thin-film transistors using a simple water treatment. Advanced Electronic Materials 1, 1500014 (2015).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics