Mechanical Engineering

Potential for a cleaner blend of fuel

A technique modeling the combustion characteristics of gasoline blended with biofuels for cleaner and more efficient fuels.

An approach to modeling the combustion characteristics of gasoline blended with biofuels provides valuable insights into the combustion and potential of this fuel combination—it also helps with KAUST’s quest to develop fuels that are less polluting and better performing.

The burning of automotive fuels, like gasoline, releases large amounts of greenhouse gases and is a major contributor to climate change. Developing greener and more efficient fuels is a huge challenge for the transportation industry.

This led Aamir Farooq and Ph.D. student Ahfaz Ahmed from KAUST to collaborate with the Fuel Technology Team at Saudi Aramco and researchers from the National University of Ireland Galway, in developing an innovative method for investigating the combustion of bioethanol-blended gasolines.

“As we move toward new engine technologies, fuel characteristics play a very important role in optimizing engine efficiency and minimizing emissions,” explains Farooq. “Our aim was to produce a model for simulating fuel-engine interactions for fuels containing large fractions of bioethanol.”

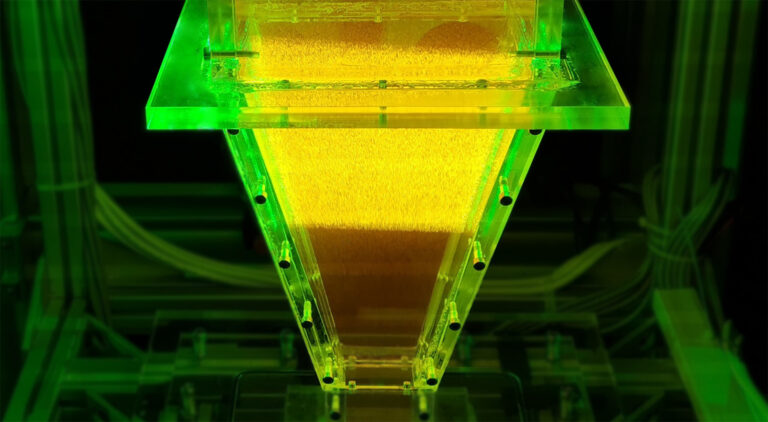

The researchers first prepared two high-octane gasolines blended with different amounts of bioethanol and observed the autoignition behavior of the fuels over a wide range of pressures, temperatures and air-to-fuel ratios. At high temperatures, the team used a high-pressure shock tube to observe the reaction. But combustion takes longer at intermediate and low temperatures, so the team used a rapid compression machine to observe reactivity.

Because gasolines are complex fuels containing hundreds of different chemical compounds, the team also used three types of surrogate fuels containing several reference components, which allowed them to simulate the combustion of the bioethanol-blended gasolines and model their ignition delay times.

“The ignition delay time is an important property of a fuel and has a significant influence on engine design and operation,” says Ahmed. “The use of high-fidelity surrogate fuels allowed us to model the ignition delay times for these biofuel-blended gasolines, and provided us with deeper insights into how the biofuel content alters the combustion behavior compared to regular gasoline.”

Despite the different rate of evolution of chemical species during combustion, the researchers found that at high temperatures the blended fuels exhibited similar autoignition characteristics, but at intermediate temperatures, the fuel with higher octane rating and higher ethanol content exhibited longer ignition delay times.

“We plan to explore the ignition characteristics of two more biofuels—methanol and dimethyl ether—after they have been blended with regular gasoline and diesel,” says Farooq.

References

-

Lee, C., Ahmed, A., Nasir, E.F., Badra, J., Kalghatgi, G. Sarathy, S.M., Curran, H. & Farooq, A. Autoignition characteristics of oxygenated gasolines. Combustion and Flame 186, 114-128 (2017).| article

You might also like

Mechanical Engineering

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering

Turbulent flow shows surprise patterns that could help boost efficiency

Mechanical Engineering