Computer Science | Electrical Engineering

Better connection for monitoring helps heart patients and healthcare staff

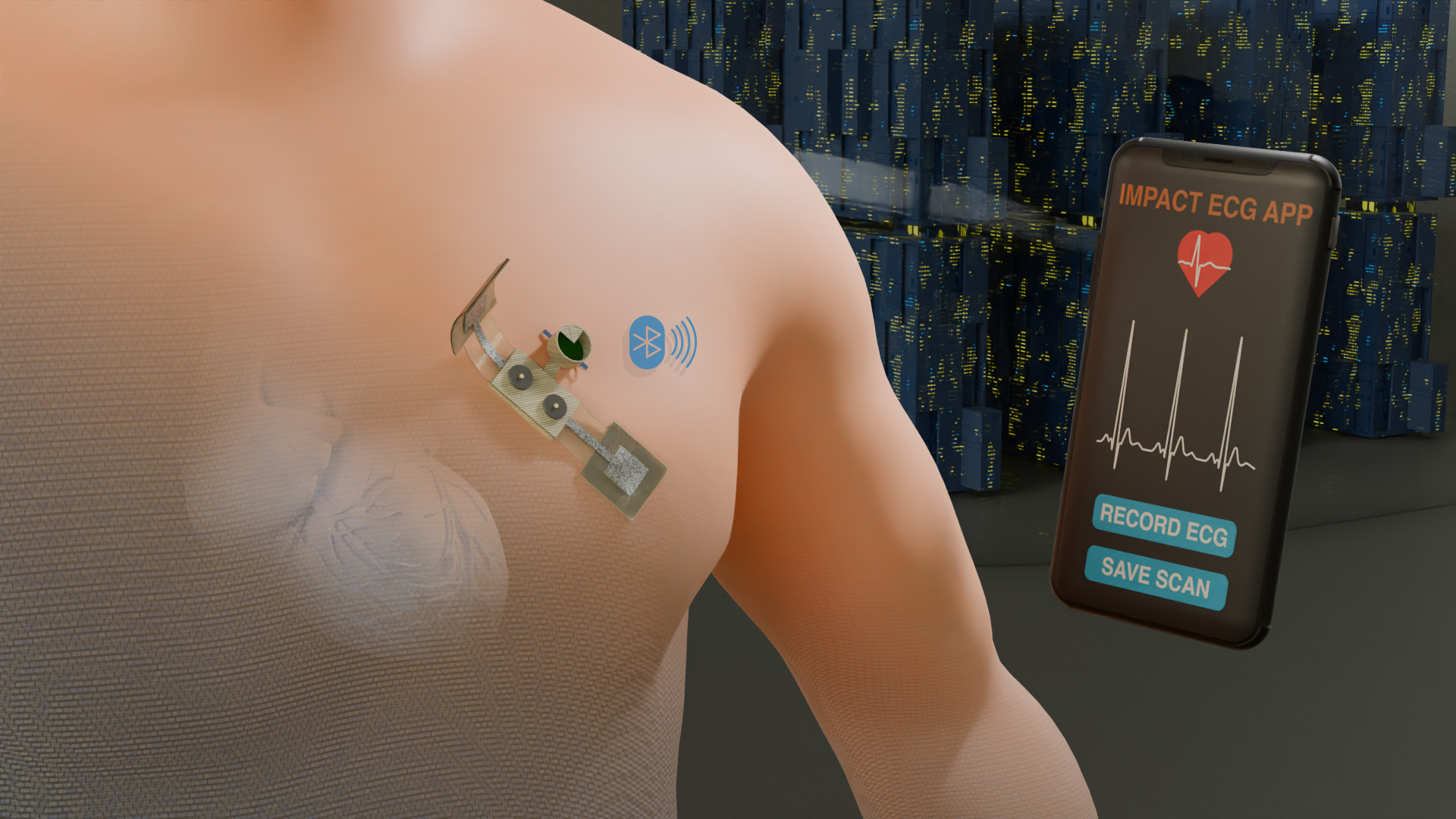

An innovative use of screen printing to assemble the key components of wet ECG electrodes enables remote monitoring at extended range and improves the experience for patients and healthcare staff.

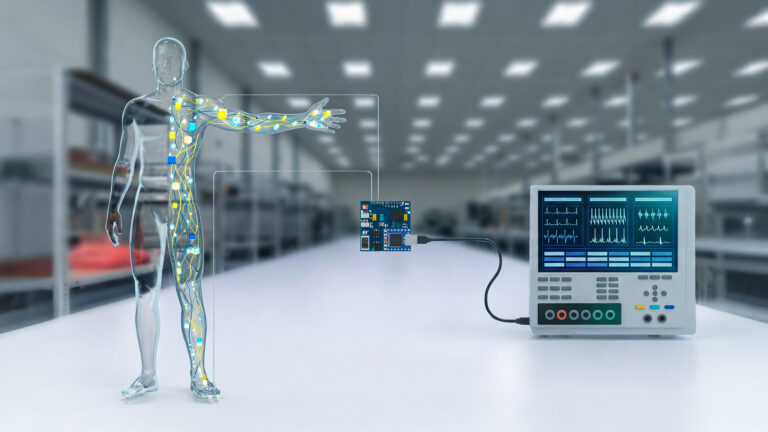

Improved and lower cost electrodes for electrocardiogram (ECG) monitoring of heart health have been developed using screen-printed wet sensors. These interact more gently with a patient’s skin than commercial electrodes, and can be used for remote monitoring by wireless communication with four times the range of existing technology.

ECG monitoring of heartbeat is the most immediate and frequently used procedure for assessing heart health and diagnosing problems. Existing electrodes that collect the electrical activity of the heart can cause skin irritation, especially if they need to be attached for extended times. The wires that carry the signals from conventional systems also obstruct movement and can restrict access by healthcare workers. Existing electrodes are also more expensive than the new type now developed by the KAUST IMPACT Lab[1].

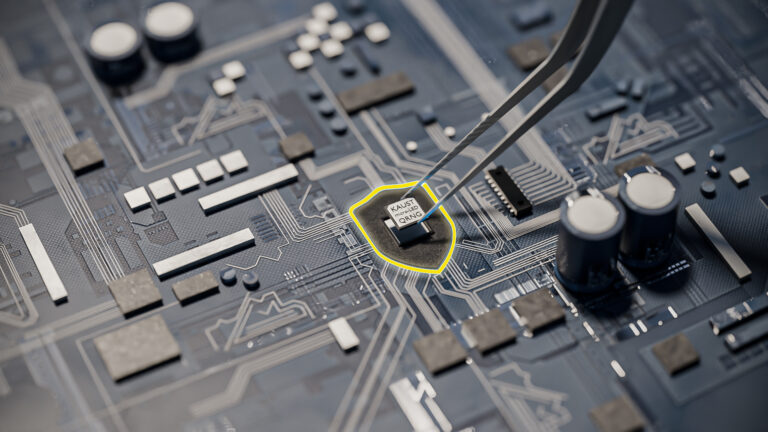

“We are the first to demonstrate the use of screen-printing to make all three basic components of an ECG electrode; the silver nanowire conductive part, the electrode gel and the adhesive,” says research scientist, Sakandar Rauf. These three components are attached to a flexible plastic substrate.

The team also developed an ultra-miniaturized wireless monitoring system that is only 16mm in diameter. Innovations in the antennae design achieved the four-fold increase in range, at up to 142 meters.

“This results in a much-improved user experience for patients and healthcare staff, as well as being low-cost,” adds Rauf.

When planning this research, the team were surprised to discover that little attention had been given to simple additively-printed wet ECG electrodes, despite the higher quality signals and greater comfort they offer.

“Meeting the challenge required a lot of effort to develop appropriate inks and printing processes,” says Atif Shamim, professor of electrical and computer engineering ,who led the research. “Our electrode’s performance was independently validated by two cardiologists and one family medicine consultant.”

Having demonstrated the value of the new technology in adult volunteers, the researchers now plan to develop and test its use for children, infants and newborns. “Our ultimate aim is to develop a reliable, easy to use and gentle wearable ECG system for wireless monitoring on any patient,” Shamim concludes.

The eventual move towards commercialization will be greatly assisted by the vast reduction in need for metal for the conductive part and of ECG electrode gel, than standard commercial wet ECG electrodes.

A provisional patent application has been filed for the printed wet ECG electrodes. The approach to commercializing the technology involves a partnership between the researchers at KAUST, cardiologists from King Faisal Specialist Hospital and Research Centre, and an industrial partner, Henkel Adhesive Technologies in Germany.

Reference

- Rauf, S., Bilal, R. M., Li, J., Vaseem, M., Ahmad, A. M. & Shamim, A. Fully screen-printed and gentle-to-skin wet ECG electrodes with compact wireless readout for cardiac diagnosis and remote monitoring. ACS Nano 18, 10074-10087 (2024).| article

You might also like

Bioengineering

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

Green quantum computing takes to the skies

Computer Science

Probing the internet’s hidden middleboxes

Bioscience

AI speeds up human embryo model research

Electrical Engineering

Micro-LEDs boost random number generation

Computer Science

Improving chip design on every level

Bioengineering