Chemical Engineering

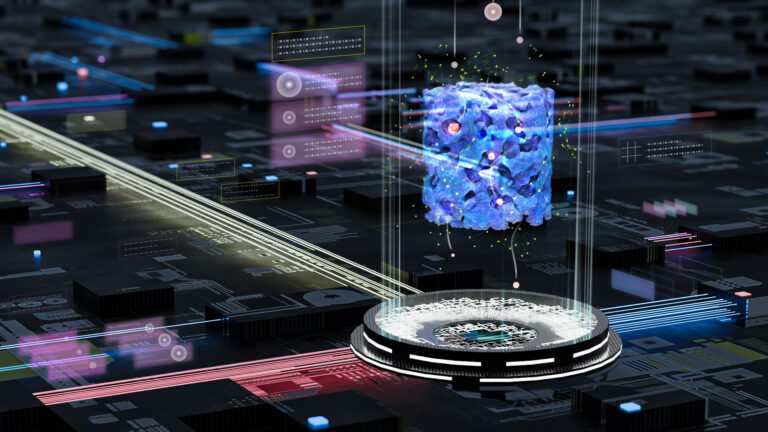

A clear window into the real world of catalysis

Systems that combine multiple spectroscopy and reactor technologies can bring a more accurate image of catalysts.

Approaches that integrate several spectroscopy and reactor technologies could help to depict catalysis better under realistic reaction conditions and support the design of more efficient and ecofriendly industrial processes.

An international KAUST-led team has refined an approach based on techniques that are already transforming the field of catalysis — operando spectroscopy and reactor techniques. They are using this to better understand catalysis for C1 chemistry reactions, which involve one-carbon molecules, such as the conversion of CO2 into methanol.[1]

These operando techniques allow researchers to simultaneously study catalysts, reaction intermediates and adsorbed species under real reaction conditions. They provide real-time performance assessments and offer valuable insights into actual reaction mechanisms, making catalysts easier to tailor to specific reactions.

Combining complementary operando techniques in a single experimental setup can yield a more comprehensive knowledge of a catalytic process. Designing and scaling up catalytic processes for industrial applications hinges on accurate kinetic information. This multitechnique approach could help capture changes in dynamic processes while also providing data about all reacting species.

Yet, optimizing these experiments remains challenging. Individual analytical techniques have limitations that constrain operating conditions, geometry and reactor materials.

To overcome these limitations, modeling approaches are shown to be useful for designing operando cells and reactors, helping to understand the kinetics of catalytic reactions and scaling-up procedures.

“Without meticulous engineering, the design of operando reactors might fall short of achieving critical objectives such as mimicking industrial conditions and delivering high-quality data,” says Vijay Velisoju, a postdoc in Pedro Castaño’s group at KAUST.

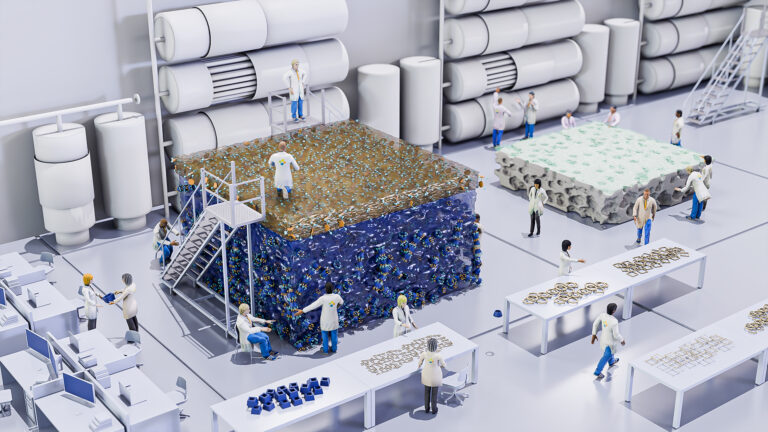

Castaño, Velisoju and co-workers have explored various spectroscopic techniques to conceive a system that simultaneously determines and couples spectroscopic and kinetic results.

With additional fluid dynamics simulations, the resulting workflow allowed the researchers to gain insight into catalyst function and evolution, tweak catalyst design and, above all, improve reactor design. Specifically, operando infrared and X-ray spectroscopies provided valuable information on the nature of the active sites and reaction mechanisms in CO2 conversion.

The researchers have custom-built reactors for advanced dynamic studies on the kinetic and deactivation mechanisms of the C1 chemistry-related catalysts. These reactors enable catalyst investigations under dynamically controllable high-temperature and high-pressure conditions. This would make it easier to study catalysts under industrially relevant conditions and enhance catalytic performance.

The team is now designing new spectroscopic cell reactors and dynamic methods for different C1 chemistries. “We will also use kinetic models derived from other sources with hydrodynamic simulations to create new reactors and better understand the ones we have,” Velisoju says.

Reference

- Velisoju, V. K., Kulkarni, S. R., Cui, M., Rabee, A. I. M., Paalanen, P., Rabeah, J., Maestri, M., Brückner, A., Ruiz-Martinez, J. & Castaño, P. Multi-technique operando methods and instruments for simultaneous assessment of thermal catalysis structure, performance, dynamics, and kinetics. Chem Catalysis 3, 100666 (2023).| article

You might also like

Chemical Engineering

Urban air pollution goes up in smoke

Chemical Engineering

Rethinking machine learning for frontier science

Chemical Engineering

Magnetic nanoparticles capture microplastics from water

Chemical Engineering

Biogas upgrading goes with a swing

Chemical Engineering

Stronger, lighter, cheaper: a new route to carbon fiber production

Chemical Engineering

Unveiling the role of biomass-burning aerosols in atmospheric reactions

Chemical Engineering

Slashing industrial emissions using a hybrid model approach

Chemical Engineering