Mechanical Engineering

Threading the way to touch-sensitive robots

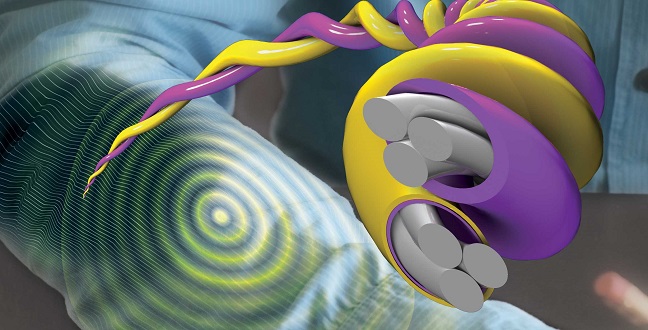

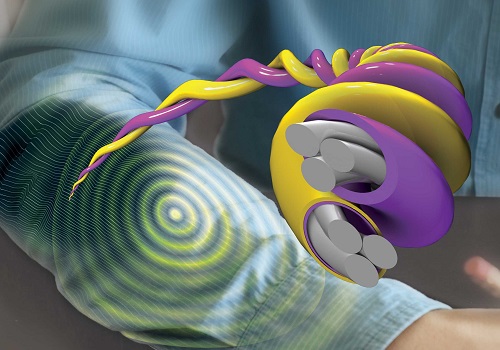

Smart threads can be woven into pressure-sensitive electronic skin for robots or medical prosthetics.

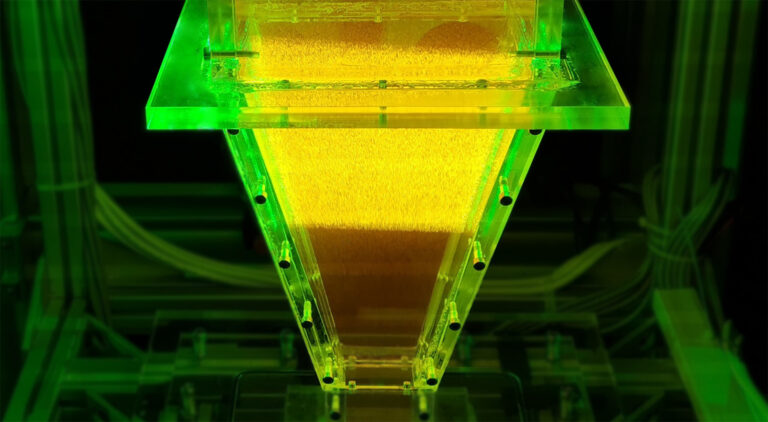

The twisted smart threads developed by KAUST researchers can be woven into pressure-sensitive electronic skin fabrics for use in novel clothing, robots or medical prosthetics.

© 2016 KAUST

Fabrics containing flexible electronics are appearing in many novel products, such as clothes with in-built screens and solar panels. More impressively, these fabrics can act as electronic skins that can sense their surroundings and could have applications in robotics and prosthetic medicine. KAUST researchers have now developed smart threads that detect the strength and location of pressures exerted on them.

Most flexible sensors function by detecting changes in the electrical properties of materials in response to pressure, temperature, humidity or the presence of gases. Electronic skins are built up as arrays of several individual sensors. These arrays currently need complex wiring and data analysis, which makes them too heavy, large or expensive for large-scale production.

Yanlong Tai and Gilles Lubineau from the University’s Division of Physical Science and Engineering have found a different approach. They built their smart threads from cotton threads coated with layers of one of the miracle materials of nanotechnology: single-walled carbon nanotubes (SWCNTs).

“Cotton threads are a classic material for fabrics, so they seemed a logical choice,” said Lubineau. “Networks of nanotubes are also known to have piezoresistive properties, meaning their electrical resistance depends on the applied pressure.”

The researchers showed their threads had decreased resistance when subjected to stronger mechanical strains, and crucially the amplitude of the resistance change also depended on the thickness of the SWCNT coating.

These findings led the researchers to their biggest breakthrough: they developed threads of graded thickness with a thick SWCNT layer at one end tapering to a thin layer at the other end. Then, by combining threads in pairs—one with graded thickness and one of uniform thickness—the researchers could not only detect the strength of an applied pressure load, but also the position of the load along the threads.

“Our system is not the first technology to sense both the strength and position of applied pressures, but our graded structure avoids the need for complicated electrode wirings, heavy data recording and analysis,” said Tai.

The researchers have used their smart threads to build two- and three-dimensional arrays that accurately detect pressures similar to those that real people and robots might be exposed to.

“We hope that electronic skins made from our smart threads could benefit any robot or medical prosthetic in which pressure sensing is important, such as artificial hands,” said Lubineau.

References

- Tai, Y. & Lubineau, G. Double-twisted conductive smart threads comprising a homogeneously and a gradient-coated thread for multidimensional flexible pressure-sensing devices. Advanced Functional Materials 26, 4078-4084 (2016).| article

You might also like

Mechanical Engineering

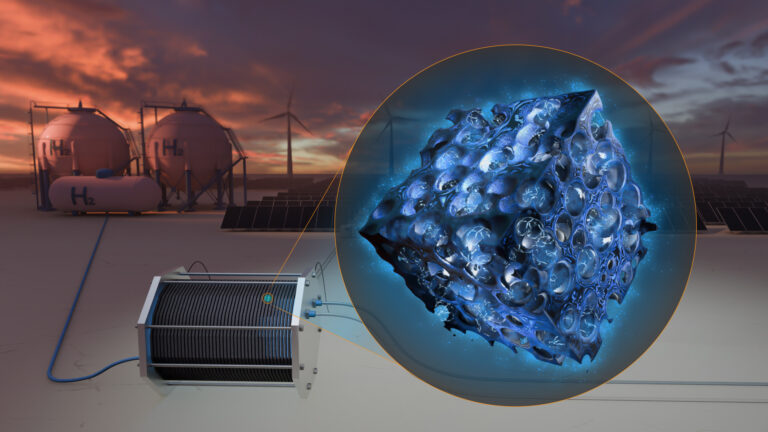

Green hydrogen from fluctuating power sources

Mechanical Engineering

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

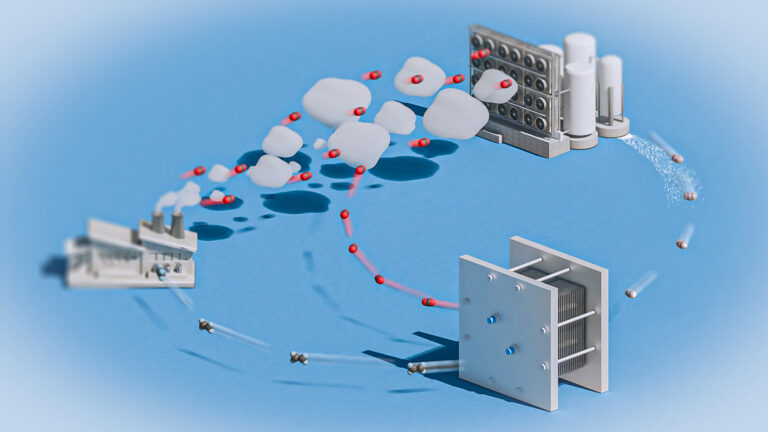

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering