Chemical Engineering

Renewable route to rubber material

A venerable industrial method for making butadiene bounces back to prominence.

A key ingredient in the manufacture of car tires and sneaker soles could be made sustainably, following new analysis of an old catalytic process. Butadiene, an essential component of synthetic rubber, is currently produced by the petrochemical industry from fossil reserves. But it could be efficiently made in a one-step reaction from renewable ethanol using a modernized version of an unusual old catalyst.

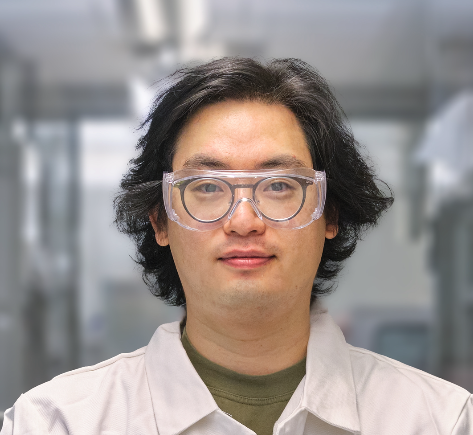

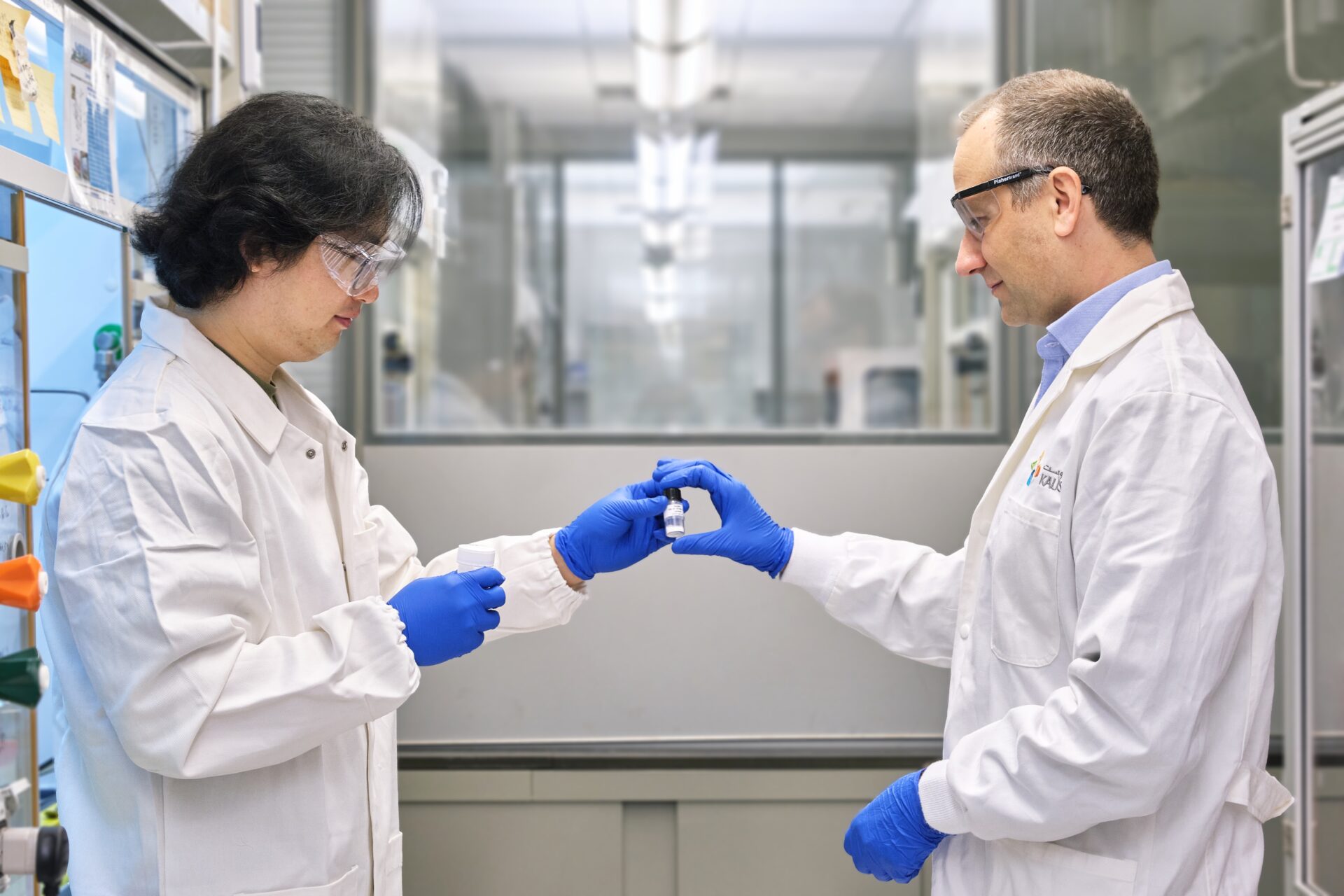

“Butadiene is currently produced as a byproduct of the petrochemical industry, which can lead to shortages in its supply,” explains Sang-Ho Chung, a research scientist in the labs of Javier Ruiz-Martinez, with whom he co-led the work[1]. “Also, these routes are clearly not sustainable,” he adds.

These challenges in butadiene production have sparked renewed interest in the Lebedev process, first developed in the 1930s, that converts ethanol to butadiene in a single catalytic reactor. “Sustainable butadiene could be made by using bioethanol in the Lebedev process or even ethanol made using cutting-edge CO2-to-ethanol processes,” Chung says.

The Lebedev process is driven by silica-magnesia catalysts that are produced by an unusual method called wet kneading. The method involves combining solid catalyst precursors in water under continuous mixing. “Wet kneading is quite uncommon in catalyst preparation, but it is often applied to prepare high-performance silica-magnesia catalysts for the Lebedev process,” Ruiz-Martinez says.

However, improved wet-kneaded catalysts have mainly been discovered by trial and error. Why some catalysts outperform others is not fully understood, and “understanding how these materials form is the first step to preparing better catalysts,” Ruiz-Martinez says.

Chung, Ruiz-Martinez and their KAUST colleagues used solid-state nuclear magnetic resonance spectroscopy to study silica-magnesia catalyst formation under real wet-kneading conditions. “We found that two different catalyst particles are formed, based on the cross-deposition of silicon species onto magnesia and magnesium species onto silica,” Chung says.

Crucially, they showed that magnesium silicates on the silica particles tend to produce ethylene as an undesired side product. “With that understanding, we could synthesize just the catalyst particles that are active for butadiene production and avoid the particles that produce ethylene,” Chung says. The team also showed that the best catalysts also had certain active sites in very close proximity.

“This has helped us to work on the next generation of catalysts for this process,” Ruiz-Martinez says. “We are making good progress and already have an even more selective version, which could be a key step for commercializing the process.”

Reference

- Chung, S.-H., Li, T., Shoinkhorova, T., Ramirez, A., Mukhambetov, I., Abdou– Hamad, E., Shterk, G., Telalovic, S., Dikhtiarenko, A., Sirks, B., Lavrik, P., Tang, X., Weckhuysen, B. M., Bruijnicx, P.C.A., Gascon, J.,& Ruiz–Martinez, J. Origin of active sites on silica–magnesia catalysts and control of reactive environment in the one-step ethanol-to-butadiene process. Nature Catalysis 6, 363-376 (2023).| article

You might also like

Chemical Engineering

Urban air pollution goes up in smoke

Chemical Engineering

Rethinking machine learning for frontier science

Chemical Engineering

Magnetic nanoparticles capture microplastics from water

Chemical Engineering

Biogas upgrading goes with a swing

Chemical Engineering

Stronger, lighter, cheaper: a new route to carbon fiber production

Chemical Engineering

Unveiling the role of biomass-burning aerosols in atmospheric reactions

Chemical Engineering

Slashing industrial emissions using a hybrid model approach

Chemical Engineering