Mechanical Engineering

Know your blends

Experimental and numerical studies reveal the combustion properties of blended fuels at elevated pressures.

The study’s authors obtained an empirical correlation for deriving laminar burning velocities at elevated pressures up to three megapascals.

© 2015 Alamy

A new understanding of fuel combustion properties from KAUST research shows promise for gasoline alternatives1.

The development of clean and energy-efficient internal combustion engines demands specially formulated fuels with optimal burning characteristics over a wide range of operating temperatures and pressures. However, studying the combustion properties of conventional gasoline is made difficult because of gasoline’s complexity – it is a blend of hundreds of different hydrocarbons, including additives and fuel stabilizers.

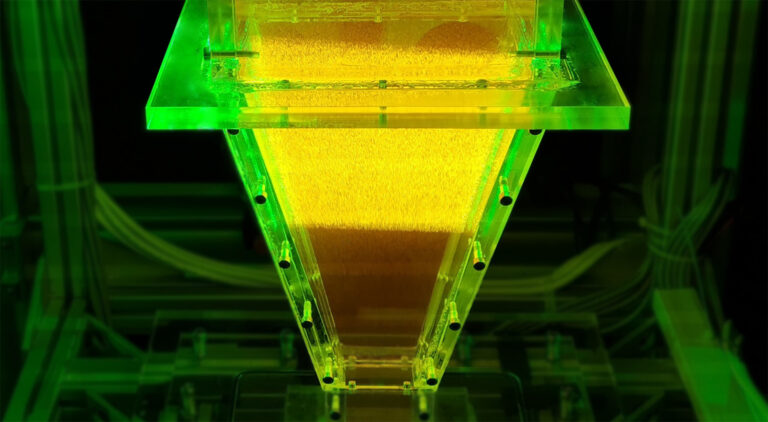

Suk Ho Chung and colleagues at the University’s Clean Combustion Research Center (CCRC) measured the laminar burning velocities of iso-octane, n-heptane, toluene and blended fuels, including primary reference fuels (such as mixtures of iso-octane and n-heptane) and toluene reference fuels (such as mixtures of iso-octane, n-heptane, toluene), with different performance rating known as the research octane numbers (such as 70, 85 and 95).

The data Chung’s team obtained from experimental and numerical studies has important implications for developers of “fuel surrogates” that aim to emulate the physical and chemical properties of gasoline.

Laminar burning velocity or laminar flame speed is the speed at which an unstretched laminar flame travels through a motionless mixture of unburned reactants. A major objective in developing fuel surrogates is to create mixtures with laminar burning velocities and performance, such as research octane numbers, that can match those of gasoline, particularly at elevated pressures.

To measure laminar burning velocities, Chung and co-workers ignited different fuels at the center of a spherical stainless steel combustion chamber. They captured images of the spherically propagating flame through a high-speed camera and calculated the laminar burning velocities by analyzing the flame images using special computer software.

The experiments yielded results consistent with those predicted by numerical simulations for pressures up to 0.6 megapascals. In addition, the scientists derived an empirical correlation between the laminar burning velocity and pressures up to three megapascals — pressures not attainable in the experiment— through extrapolation of data. The correlation is extremely useful because it shows the exact ratios of iso-octane, n-heptane and toluene needed to make fuel surrogates that emulate gasoline of a particular research octane number.

“A good understanding of the laminar burning velocity is key to developing novel fuel blends and surrogates designed for advanced internal combustion engines over a range of stoichiometries, pressures and temperatures,” Chung said.

Apart from laminar burning velocity, the researchers also determined other combustion parameters, including the fuel’s Markstein length, Pecklet number and Karlovitz number, which have important implications for assessing flame behavior.

References

- Mannaa, O., Mansour, M.S., Roberts, W.L. & Chung, S.H. Laminar burning velocities at elevated pressures for gasoline and gasoline surrogates associated with RON. Combustion and Flame 162, 2311–2321 (2015). | article

You might also like

Mechanical Engineering

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering

Turbulent flow shows surprise patterns that could help boost efficiency

Mechanical Engineering