Chemical Engineering

Burning a better biofuel

Chemical reaction modeling and combustion experiments reveal how 2-methylbutanol would behave in advanced engines.

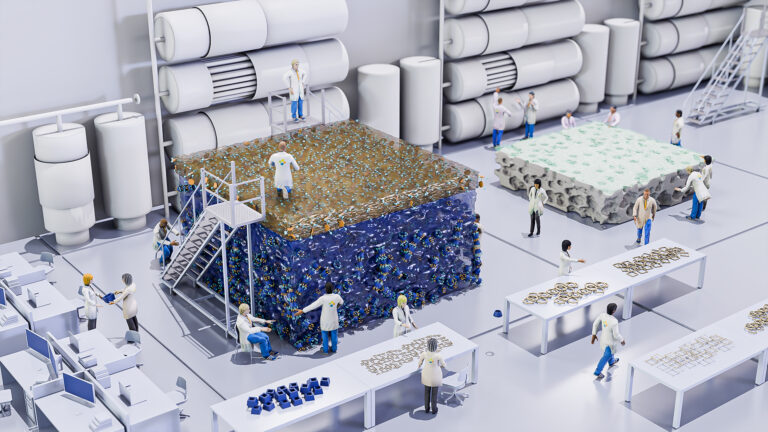

A high-pressure shock tube more than 13 meters long can reveal how fuels burn at very high pressures.

© 2015 KAUST

A next-generation biofuel has promising combustion properties that could make it a viable replacement for conventional fossil fuels, suggests a modeling study by researchers from KAUST1.

Burning traditional liquid fuels such as gasoline produces the greenhouse gas carbon dioxide and particles and nitrogen oxide gases that can harm human health. Fuels containing oxygen atoms can reduce these emissions if they are produced from renewable resources — by fermenting plant sugars into ethanol, for example — they can further offset carbon dioxide emissions.

Ethanol, however, is a short-chain alcohol, which leads to practical problems. It has a relatively low energy density and can be difficult to store because it readily absorbs water.

“Longer-chain alcohols could significantly increase the biofuel content in blended fuels due to their higher energy content, better engine compatibility and lower water solubility,” noted Mani Sarathy of the University’s Clean Combustion Research Center (CCRC).

Sarathy’s team studied the combustion of a longer-chain bio-derived alcohol called 2-methylbutanol to reveal how it would burn in clean, fuel-flexible and efficient engines that operate at higher pressures than today’s engines.The researchers measured 2-methylbutanol’s laminar flame speed, which indicates how quickly the fuel mixture burns after ignition, and found similar results to conventional liquid fuels.

They also burned 2-methylbutanol in a high-pressure shock tube that can heat and compress a mixture of fuel and air almost instantaneously. They tested three different fuel concentrations at pressures of 20 bar and 40 bar and temperatures from 477 to 977 degrees Celsius.

At intermediate temperatures, the time delay between compression and ignition was similar to another longer-chain alcohol called isopentanol. Ignition was faster, however, at higher temperatures, suggesting that 2-methylbutanol would be suitable for use in compression-ignition engines similar to those that burn diesel.

The team also created a computational model of all the chemical reactions involved in combustion that contained 469 different molecules and 2504 reactions.

“We need this comprehensive set of chemical reactions and their rates to be able to accurately predict the rate of energy release, soot and pollutant formation, ignition behavior and flame characteristics,” said Sarathy. “This can represent how next-generation fuels behave in internal combustion engines.”

The model identified a particularly significant low-temperature reaction between molecular oxygen and a reactive “radical” called α-hydroxypentyl, which forms a stable aldehyde molecule and hydroperoxy radicals. Changes in this reaction’s rate had the most marked effect on the ignition delay.

Having proved the value of the model, Sarathy hopes to adapt it to study the combustion properties of other biofuels under various engine conditions.

References

- Park, S., Mannaa, O., Khaled, F., Bougacha, R., Mansour, M. S. et al. A comprehensive experimental and modeling study of 2-methylbutanol combustion. Combustion and Flame 162, 2166-2176 (2015). | article

You might also like

Chemical Engineering

Urban air pollution goes up in smoke

Chemical Engineering

Rethinking machine learning for frontier science

Chemical Engineering

Magnetic nanoparticles capture microplastics from water

Chemical Engineering

Biogas upgrading goes with a swing

Chemical Engineering

Stronger, lighter, cheaper: a new route to carbon fiber production

Chemical Engineering

Unveiling the role of biomass-burning aerosols in atmospheric reactions

Chemical Engineering

Slashing industrial emissions using a hybrid model approach

Chemical Engineering