Material Science and Engineering

Graphene crystals grow better under copper cover

An interface-templated method enhances the crystallinity of large single-layer graphene sheets on insulating supports.

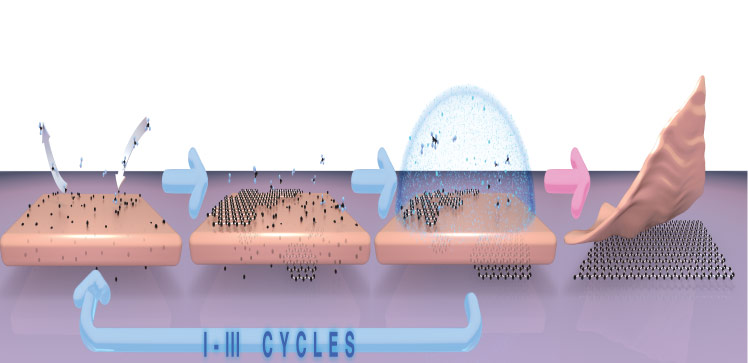

Schematic animation of the liquid nitrogen-assisted separation methods.© Springer Nature; Li, J. et al (2022)

Schematic animation of direct growth of single-crystalline graphene on insulating substrates by MPE–CVD.© Springer Nature; Li, J. et al (2022)

An approach that produces single-crystal graphene sheets on large-scale electrically insulating supports could help with the development of next-generation nanomaterial-based devices, such as very light and thin touchscreens, wearable electronics and solar cells.

Most graphene-based electronic devices require insulating supports. Yet, high-quality graphene films destined for industrial use typically are grown on a metal substrate, such as copper foil, before being transferred to an insulating support for device fabrication. This transfer step can introduce impurities that affect how well the device performs. Efforts to grow graphene on insulating supports have not been able to produce the required high-quality single crystals.

“If graphene can be grown on an insulating substrate with a clean interface, certain devices might function better,” says Ph.D. student Bo Tian, who co-led the study under Xixiang Zhang’s supervision. “This also opens the door to new types of graphene-based nanodevices,” he explains.

Zhang, Tian and coworkers from Asia and Europe tweaked the chemical vapor deposition method, which relies on the copper-catalyzed decomposition of methane into carbon precursors, to generate smooth single-crystal graphene monolayers on wafer-scale single-crystal substrates called c-plane sapphire.

Schematic animation of the liquid nitrogen-assisted separation methods.© Springer Nature; Li, J. et al (2022)

The researchers converted polycrystalline copper foil into its single-crystal counterpart Cu(111) on the sapphire surface and introduced active carbon atoms from the metal substrate-catalyzed decomposition of methane on the resulting film. The carbon atoms diffused through the metallic film toward the copper–sapphire interface, which acted as a template, and formed well-oriented graphene islands that, after several growth cycles, merged to yield a sheet.

In addition to weak surface interactions, the copper film and sapphire displayed similar crystal lattice symmetry to that of graphene, Tian says, which explains the high crystallinity of the graphene monolayer.

The researchers etched away any graphene that had accumulated on top of the copper film using a hydrogen–argon plasma to facilitate carbon diffusion. They immersed the samples in liquid nitrogen before heating them rapidly to 500 degrees Celsius, making the copper film easy to peel off while keeping the graphene monolayer intact.

Field-effect transistors manufactured on the sapphire-grown single-crystal graphene monolayer exhibited excellent performance with higher carrier mobilities. The superior electronic performance of the graphene grown on sapphire results from its higher crystallinity and fewer folds on the surface, Tian explains.

“Our team is now trying to grow other two-dimensional materials on the insulator-supported graphene to build functionalized large-scale heterostructures,” Tian says. These heterostructures held together by van der Waals interactions are expected to be useful in future nanodevices.

References

- Li, J., Chen, M., Samad, A., Dong, H., Ray, A., Zhang, J., Jiang, X., Schwingenschlögl, U., Domke, J., Chen, C., Han, Y., Fritz, T., Ruoff, R.S., Tian, B. & Zhang, X. Wafer-scale single-crystal monolayer graphene grown on sapphire substrate. Nature Materials, advance online publication, 22 January 2022.| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics