Chemical Engineering

Scientists cut their teeth on new separation technology

An energy efficient membrane technology could lead to a low-cost and environmentally sustainable separation technique.

A new membrane-based separation technology could provide an efficient and environmentally sustainable alternative to current nanofiltration methods based on organic solvents.

Conventional thermal-based separation technologies consume significant amounts of energy because they require heat to drive the separation processes and typically account for anywhere between 40-70 percent of the total capital and operational cost of a chemical plant.

Alternatively, separation technologies that use mixed-matrix membranes (MMMs) containing metal-organic framework (MOF) fillers do not require heat and consume up to 90 percent less energy than distillation, resulting in a more efficient separation process with sustainability benefits, in addition to added energy and cost savings.

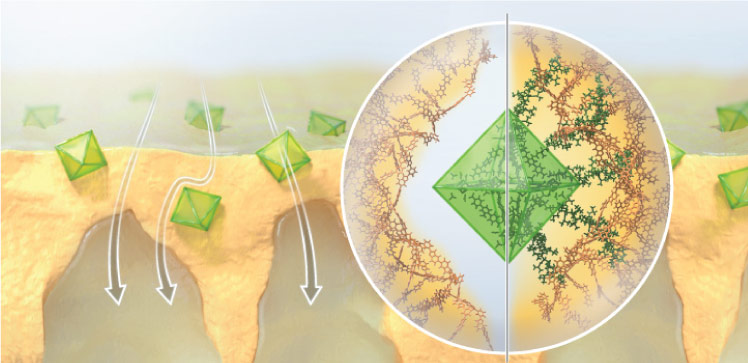

However, the lack of interfacial adhesion between the polymer matrix and the MOF filler causes nanosized gaps, creating defects and voids on the membrane’s surface, which can diminish the selectivity of the MMM.

Inspired by nature, Gyorgy Szekely and Rifan Hardian from KAUST, working with scientists from the University of Manchester, Hokkaido University and the Japan Science and Technology Agency, have overcome the interfacial adhesion problems by fabricating MOF nanoparticle fillers that are more compatible with the MMM’s polymer matrix. This eliminates the formation of pinholes at the filler–matrix interface and significantly improves the performance of the membranes.

“The approach was inspired by cementum, the tissue layer that covers the root of the tooth, which is connected to the surrounding tissues by collagen fibers,” says Hardian. “In our case, the MOF crystal is connected to or entangled with the surrounding polymer matrix by grafting with poly(N-isopropylacrylamide).”

To fabricate the membranes, the researchers first prepared a series of MMMs using polybenzimidazole and zirconium-based MOF nanoparticles of the UiO-series, namely UiO-66-NH2, UiO-67-NH2, and UiO-68-NH2. These nanoparticles had similar chemical and surface properties but with increasing pore size, which allowed the team to investigate how various pore sizes influence the separation in MMMs.

The nanoparticles’ surfaces were then covalently grafted with poly(N-isopropylacrylamide), or PNIPAM chains, which became entangled with the MMMs polymer matrix, preventing the formation of pinholes.

Hardian says that PNIPAM is a promising candidate for polymer grafting due to its interesting hydrogen-bonding properties and easy synthesis. “And due to the regularity of the pore arrangement and tunability of the pore size in the MOF structure, we can now fine-tune the molecular sieving performance of the MMMs,” says Hardian.

The researchers are now investigating the possibility of enhancing the MOF/matrix adhesion without the need for surface grafting.

By increasing the chemical compatibility of the fillers and the polymers in MMMs, the work “may eliminate the necessity of grafting agents, making the membrane fabrication process simpler and more environmentally sustainable,” says Szekely.

References

-

Cseri, L., Hardian, R., Anan, S., Vovusha, H., Schwingenschlogl, U., Budd, P.M., Sada, K., Kokado, K. & Szekely, G. Bridging the interfacial gap in mixed-matrix membranes by nature-inspired design: precise molecular sieving with polymer-grafted metal–organic frameworks. Journal of Materials Chemistry A 9, 23793–23801 (2021).| article

You might also like

Chemical Engineering

Urban air pollution goes up in smoke

Chemical Engineering

Rethinking machine learning for frontier science

Chemical Engineering

Magnetic nanoparticles capture microplastics from water

Chemical Engineering

Biogas upgrading goes with a swing

Chemical Engineering

Stronger, lighter, cheaper: a new route to carbon fiber production

Chemical Engineering

Unveiling the role of biomass-burning aerosols in atmospheric reactions

Chemical Engineering

Slashing industrial emissions using a hybrid model approach

Chemical Engineering