Material Science and Engineering

Solar perovskite production on a roll

High-performance perovskite solar cells are made using a manufacturing-friendly liquid-based process suitable for roll to roll production.

Advanced ink formulations could be the key to turning perovskite solar cells (PSCs) from heroes of academic labs into commercially successful products. Researchers at KAUST have developed a perovskite ink tailor-made for a mass manufacturing process called slot-die coating, producing PSCs that captured solar energy with high efficiency. The ink could also be coated onto silicon to create perovskite/silicon tandem solar cells that capture even more of the Sun’s energy.

“PSCs have shown a lot of promise in lab-scale work over the past decade,” says Anand Subbiah, a postdoc in Stefaan De Wolf’s lab. “As a community, we need to start looking at the stability and scalability of PSC technology,” he says.

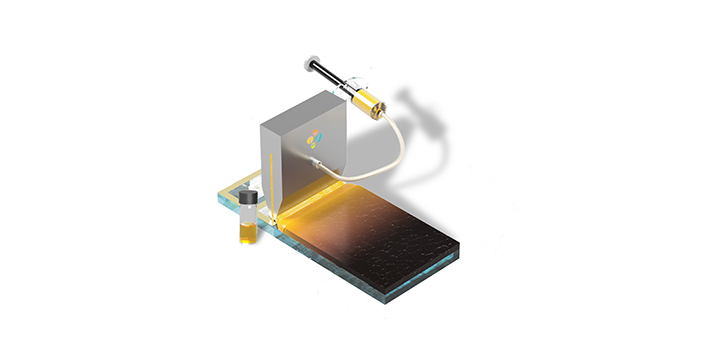

PSCs made in research labs are typically made by spin-coating, which is unsuited to mass manufacture. Slot-die coating, in contrast, is a manufacturing technique used industrially for almost 70 years. “The process involves continuously and precisely forcing an ink through a narrow slit that is moved across the substrate to form a continuous film,” Subbiah says. “This high-throughput technique would allow for roll-to-roll fabrication, similar to printing newspapers.”

To produce high-efficiency slot-die coated PSCs, the team faced several challenges. Some of the best-performing spin-coated PSCs combine the perovskite with a poly(triarylamine) (PTAA) transport layer, but PTAA is hydrophobic and highly repellent to liquid perovskite ink. Adding a surfactant to the ink formulation overcame the repellence, resulting in better quality interface and films and better device performance, Subbiah says. The team also switched the ink to a lower-boiling solvent, reducing ink drying time without the need for further processing steps.

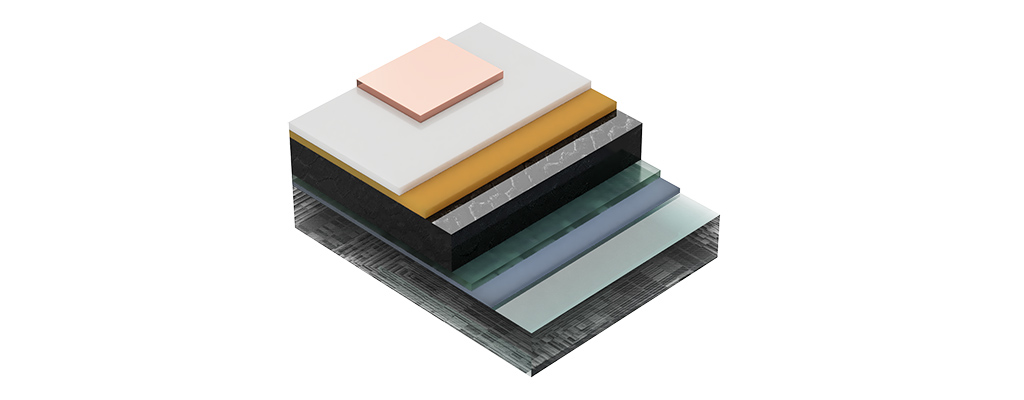

The planar p-i-n device architecture of the perovskite solar cell employed in the study.

© 2020 KAUST

Overall, the team’s optimized slot-die coated PSCs captured solar energy with up to 21.8 percent efficiency, a significant improvement over the 18.3 percent previously recorded for PSCs made this way.

Even more significantly, from a commercial standpoint, was that the ink could readily be coated onto textured silicon to produce a perovskite/silicon tandem solar cell, Subbiah says. “We were also able to make the very first slot-die coated silicon-perovskite monolithic tandem solar cell, recording a 23.8 percent efficiency,” he says.

“The development of scalable deposition techniques for perovskite solar cells is essential to bring this technology from the research labs to the market,” De Wolf says. “Our next steps are making large-area devices and modules using our developed technology and testing their stability in the lab and the outdoors, while continuing to improve performance.”

References

- Subbiah, A.S., Isikgor, F. H., Howells, C.T., De Bastiani, M., Liu, J., Aydin, E., Furlan, F., Allen, T.G., Xu, F., Zhumagali, S., Hoogland, S., Sargent, E.H., McCulloch, I. & De Wolf, S. High-performance perovskite single-junction and textured perovskite/silicon tandem solar cells via slot-die-coating. ACS Energy Letters 5, 3034–3040 (2020).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics