Mechanical Engineering

Firing up a clean chemistry revolution

Plasma technology could help the petrochemical industry transition to an electrified, decarbonized future.

The shift to a future marked by carbon-free renewable energy sources is being explored by KAUST researcher Min Suk Cha as societies seek to end our reliance on fire. Cha and his team, including postdoc Ramses Snoeckx are researching electrically generated plasmas as the future of chemical synthesis and manufacturing to replace combustion-driven processes.

“The importance of fire—its acquisition, control or theft—is a recurring theme in the mythologies of cultures across the globe,” says Cha, from the Clean Combustion research center. Fire provided our ancestors with the means to cook, heat, hunt, create and protect. Over time, our reliance on fire has only grown. “Since the industrial revolution, combustion has become the foundation of power generation, transportation, smelting and material processing,” says Cha. “This was followed rapidly with advances in petrochemistry, producing fertilizers; materials, such as plastics; medicine; and much more.”

The downside of fire has become all too clear as the climate-altering side effects of the CO2 emissions it generates. “But renewable electricity offers a pathway forward,” Cha says. Wherever fire has led, electricity has followed, he notes. “Even though we cannot abandon fossil fuels entirely just yet because of energy demands, a controlled transition from the era of fire to an electrified future appears imperative,” Cha says.

Electric potential

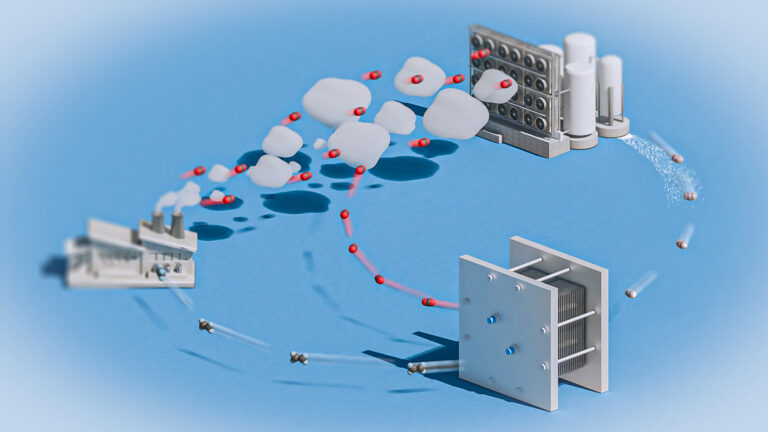

As energy production shifts from fossil fuel combustion to renewable alternatives, the chemical industry could also transition from combustion-driven to renewables-driven processes. Rather than simply using renewable electricity as an alternative heat source, Cha is investigating a potentially more efficient alternative: directly applying a voltage to the chemical starting materials to trigger new chemical production by generating a plasma. “Plasma technology provides us with the opportunity to utilize the full potential of electrical energy,” Cha says.

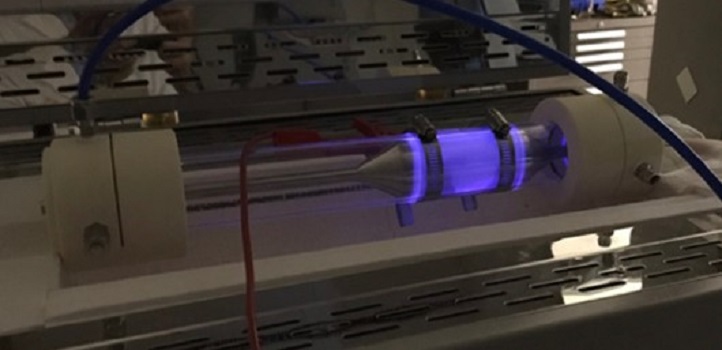

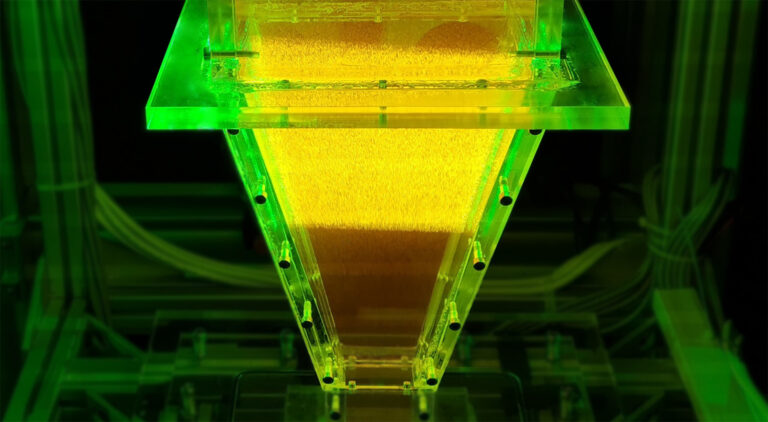

Plasma-driven reactions often emit light as components in the mixture shed energy following electron impacts.

© 2020 Ramses Snoeckx

Plasma is often described as the fourth state of matter, in line with solid, liquid and gas. A plasma is a gas in which some or all of the consistent molecules have had electrons ripped free, forming a complex cocktail of electrons, ions, atoms and molecules. Plasmas are common in the natural world, from the center of stars to lightning strikes. They can also be generated and maintained artificially by applying a strong electric field for example. The field accelerates the free electrons, which then canon into other molecules in the mixture, knocking free further electrons to sustain the plasma.

A direct strike by a speeding electron on a molecule can knock another electron free—or it can crack the molecule apart. A water molecule, for example, can split into a hydrogen radical and a hydroxyl radical. “We want to use this type of dissociation as a source of chemical reaction,” Cha explains. Although water molecules or CO2 molecules could be split by heating, it would require a huge amount of energy to heat up the whole gas sample. Using an electric field to accelerate electrons is a far more energy-efficient approach. “We can selectively transfer the electrical energy into the motion of charged particles.”

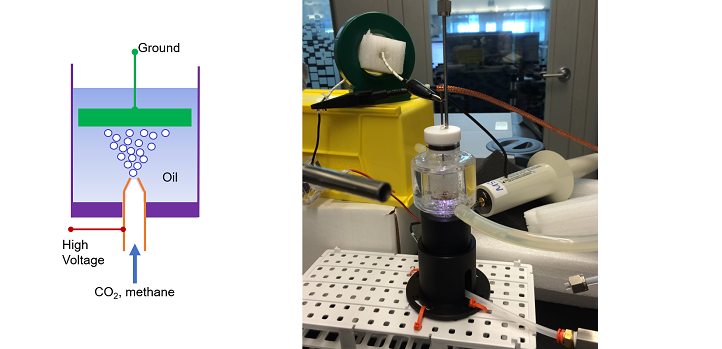

One application of plasma chemistry the team is exploring is to crack apart CO2 molecules, as the first step in turning captured CO2 emissions into valuable chemicals.1 By feeding a mixture of methane and CO2 into a plasma reactor, researchers can trigger a reaction called dry reforming, which turns the two starting gases into hydrogen and carbon monoxide. This mixture, known as syngas, is a major chemical feedstock used in synthetic liquid fuel production, for example.

Plasma-driven molecular dissociation can also be used for hydrocarbon reforming, taking basic chains of carbon and hydrogen atoms and turning them into something more valuable.2 “For example, I could turn CO2, water and an alkane (a basic hydrocarbon) into an alcohol, an alternative fuel,” Cha says.

Control reaction

“The great challenge with plasma-driven chemistry,” says Cha, “is maximizing the yield of the desired product from the cocktail of reactive species generated under plasma conditions. My research is focused on how to control the plasma chemistry to make certain target chemicals,” he says.

Bubbling reactant gases through an oil or liquid hydrocarbon, such as octane, under plasma reforming conditions can convert the basic hydrocarbon into value-added products

© 2020 Xuming Zhang and Min Suk Cha.

One advantage of plasma-driven over conventional chemistry is that researchers have two independently adjustable ways to supply the reaction with energy. They can separately alter the starting temperature of the reactant gases and the electrical energy applied to accelerate the free electrons in the mixture. “We have shown that electron impact reactions can initiate a chemical reaction regardless of initial conditions, and it is the thermochemistry, governed by the gas temperature, that has a dominant effect on product selectivity,” Cha says. “Combining plasma with a catalyst can also improve reaction selectivity,” he adds.

“Once control over product formation and selectivity for plasma processes is fully understood, this could pave the way for using plasmas for the on-demand production of tailored chemicals and fuels using renewable electricity,” Cha says. Plasmas are already used industrially to manufacture computer chips, he adds. “The transition toward an electrified future is already kindling and we must prepare ourselves for the challenges and opportunities that electrification presents.”

Humanity’s transition from combustion to electricity may seem a very modern story, but our recognition of electricity’s superiority over fire has a long history. “The Greek God Zeus, who punished Prometheus for giving fire to humankind, symbolized his might through lightning—which, of course, is electricity,” Cha says. Not just electricity, but an electrically generated plasma.

References

-

Wang, W., Snoeckx, R., Zhang, X., Cha, M.S. & Bogaerts, A. Modeling plasma-based CO2 and CH4 conversion in mixtures with N2, O2, and H2O: The bigger plasma chemistry picture. Journal of Physical Chemistry C 122, 8704-8723 (2018).| article

- Zhang, X. & Cha, M.S. Tailored reforming of n-dodecane in an aqueous discharge reactor. Journal of Physics D: Applied Physics 49, 175201 (2016).| article

You might also like

Mechanical Engineering

Cracking clean fuel combustion

Mechanical Engineering

Tiny sensor could transform head injury detection

Mechanical Engineering

Electrocatalytic CO2 upcycling excels under pressure

Chemical Engineering

Rethinking machine learning for frontier science

Mechanical Engineering

Falling water forms beautiful fluted films

Mechanical Engineering

Innovative strain sensor design enables extreme sensitivity

Mechanical Engineering

Turbulent flow shows surprise patterns that could help boost efficiency

Mechanical Engineering