Material Science and Engineering

Branching out into solar cells

The fabrication of branched titanium dioxide nanomaterials enhances the connectivity in solar cells for a better performance.

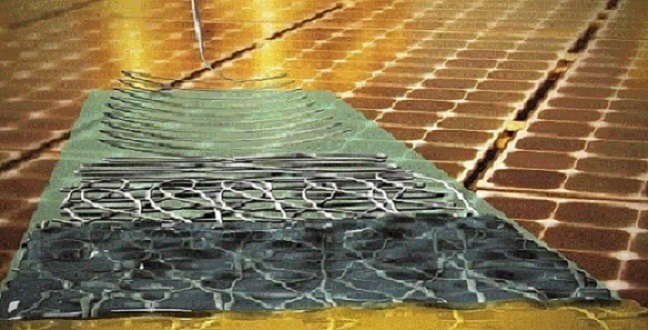

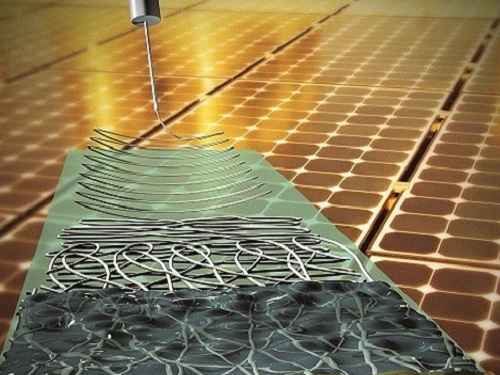

Schematic of the low-cost fabrcation of titanium dioxide nanomaterials by electrospinning.

© 2015 Wiley

Electrical contacts made of branched titanium dioxide nanowires developed by developed by researchers from KAUST could improve the efficiency of solar cells.

Titanium dioxide is a white pigment commonly used in paint and a versatile electronic material commonly used in solar cells. It is a cheap and abundant compound and has similar electronic states to those of the light-absorbing compounds used in photovoltaics.

This match ensures that electrical charges are efficiently funnelled away from the active region of a solar cell into the titanium dioxide and from there towards the electrical contacts of the device. “It is the most successful electron transporting material in hybrid organic/inorganic photovoltaics,” explains research leader Aram Amassian.

To ensure good contact between the titanium dioxide and the solar cell material, the titanium dioxide needs a very large surface area for maximum capture of electrical charges. The surface area can be expanded through the use of nanostructured materials such as meshes made from nanowires. These meshes have not been able to effectively transport the electrical charges across the nanowires.

Different architectural structures could help improve charge transport — for instance branched structures would have a much stronger electrical connection. But, established techniques for growing such branched structures is inefficient and produces nanostructures with many impurities and defects.

The researchers have now established a two-stage process for an efficient fabrication of branched titanium dioxide materials. The first step is to deposit nanofibers using an electrospinning technique, where a narrow jet of a titanium dioxide solution is ejected from a needle using electrostatic charges (see image), resulting in a network of electron highways. “Electrospinning of metal oxide nanofibers has emerged as a potentially low cost, rapid and useful technique to grow one-dimensional nanostructures on a variety of substrates,” says Amassian.

In the second step these structures are heated further which results in the hydrothermal growth of branched nanostructures. The hyperbranched materials perform better than conventional nanofibers in solar cells, which indicates their potential viability in other devices such as batteries, or catalytic applications.

The team reduced the processing temperature substantially — down to 300 degrees Celsius — but the demand for a high processing temperature remains a practical barrier to the technology, says Amassian. “Future work to halve this temperature could help implement hyperbranched electron transport materials for solar cell fabrication on flexible and stretchable plastic or textile substrates.”

References

- Mahmood, K., Swain, B. S & Amassian, A. Highly efficient hybrid photovoltaics based on hyperbranched three-dimensional TiO2 electron transporting materials. Advanced Materials 27, 2814 (2015).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics