Material Science and Engineering

Self-assembled power

Rechargeable batteries to benefit from the development of lithium-loving foams.

Lithium batteries could soon enjoy puffed-up performance thanks to a highly ordered inorganic foam discovered at KAUST. The self-assembling foam features a complex hierarchical structure that allows it to repeatedly soak up and then release large quantities of lithium ions with ease. The material could become a key component of fast-charging, long-lived lithium batteries.

The inorganic substance molybdenum disulfide (MoS2) has been earmarked as a promising potential lithium-ion battery (LIB) anode material. “Its high theoretical capacity for lithium coupled with its earth abundance and its easy solution processability make MoS2 an attractive LIB anode candidate,” says Xuan Wei, a Ph.D. student in Vincent Tung’s labs, who led the work.

Typically, however, MoS2 consists of atomically thin 2D layers, stacked like sheets of paper. “This brittle layered structure lacks electrochemical stability and limits lithium-ion diffusion into and out of the material,” Wei says.

Tung and Wei, along with their collaborators at Aramco, sought to convert 2D MoS2 nanosheets into a robust 3D material suited to battery anode use. “When I joined the lab in 2018, we started to develop a technique called electrohydrodynamic (EHD) printing to build 3D structures from 2D MoS2 nanosheets,” Wei says. “Initially, we could only synthesize fluffy and irregular 3D ‘crumples,’ which were very brittle,” she recalls.

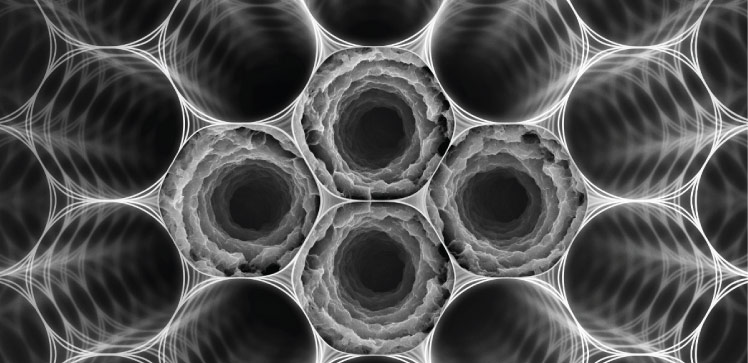

After testing dozens of conditions, the team eventually hit upon a setup in which the nanosheets form an organized stable 3D foam. “Once we found the optimum conditions, the foam self-assembly process seems to happen naturally and simply upon evaporation,” she says.

The foam possesses a highly ordered hierarchical structure, from nanoscopic structural elements up to characteristics visible to the naked eye. “This is the first such 3D foam with structural features spanning seven orders of magnitude in size, from angstrom to tens of centimeters,” Tung says.

These features were essential to the material’s excellent battery anode performance, which the team showed maintained a high lithium capacity over time. LIB anodes must withstand repeated swelling and shrinking as a large amount of lithium is absorbed and then released over each battery discharge/recharge cycle.

“These hierarchical structural elements could share the mechanical stress,” Wei says. In one test, when the team squeezed the foam to 50 percent of its usual height, rather than collapse, the foam sprang back, recovering 95 percent of its original height.

“The 3D architected MoS2 foam holds great prospects for applications that require high-power density and long cycling life, such as in wearable and implantable electric devices,” Wei says.

References

- Wei, X., Lin, C.-C., Wu, C., Qaiser, N., Cai, Y., Lu, A.-Y., Qi, K., Fu, J.-H., Chiang, Y.-H., Yang, Z., Ding, L., Ali, O. S., Xu, W., Zhang, W., Hassine, M. B., Kong, J., Chen, H.-Y. & Tung, V. Three-dimensional hierarchically porous MoS2 foam as high-rate and stable lithium-ion battery anode. Nature Communications 13, 6006 (2022).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

A single additive enables long-life, high-voltage sodium batteries

Bioengineering

Smart patch detects allergies before symptoms strike

Applied Physics

Two-dimensional altermagnets could power waste heat recovery

Applied Physics

Interface engineering unlocks efficient, stable solar cells

Applied Physics

The right salt supercharges battery lifespan

Applied Physics

Light-powered ‘smart vision’ memories take a leap forward

Applied Physics