Chemical Engineering

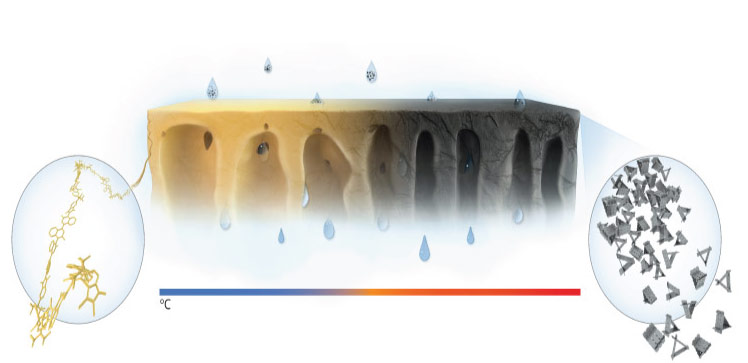

Burning membranes for molecular sieving

Heat treatment shrinks polymer’s pores to enhance solvent filtration.

A robust nanofiltration membrane that acts as a highly effective molecular sieve can avoid many of the problems with current polymer membranes.

Filtration plays a crucial role in many industries, ranging from water purification to pharmaceutical production. Organic solvent nanofiltration, for example, uses membranes with tiny pores to remove molecules that are dissolved in organic (carbon-based) solvents.

Nanofiltration is more energy efficient than alternative separation methods such as distillation. But to withstand the rigors of industrial use, nanofiltration membranes must be stable against harsh solvents, acids and bases.

“Unfortunately, the majority of polymer-based membranes exhibit poor chemical stability,” says postdoc Rifan Hardian. These membranes typically need additional chemical crosslinkers to improve their stability, which complicates their manufacture. Many membranes, as they swell and age, also tend to lose their performance and they may even break down to release trace contaminants.

Hardian and his KAUST colleagues Mahmoud A. Abdulhamid and Gyorgy Szekely have now overcome these drawbacks by creating a new kind of carbon molecular sieve (CMS) membrane that does not require additional crosslinkers.

The membrane is based on a polymer called 6FDA-DMN, which can be formed into a flat, porous membrane with good thermal stability. Baking the polymer membrane at 400–600 degrees Celsius for several hours gradually burned off some of its chemical groups to leave a tough membrane made entirely of carbon. Electron microscope images showed that at the highest temperatures, this carbonization process also shrank the membrane’s pores considerably.

After fine-tuning the conditions used to make the CMS membrane, the researchers tested its filtration abilities using solutions containing molecules with a range of sizes. The profile of molecules retained by the membrane, compared with those that passed through its pores, revealed how effective the membrane was at sieving different molecules.

The membranes prepared at 600 degrees Celsius performed best, holding back most of the smallest molecules while allowing solvent molecules to flow through. The team also found that the porous structure of the initial polymer was key to producing a CMS membrane with high solvent permeance.

“A combination of high rejection of small molecules and high solvent permeance indicate a better membrane performance,” Hardian explains. “The membranes also exhibited exceptional stability in various organic solvents, including acid and base, for a long period.”

The researchers are now working to improve the membrane’s permeance and plan to incorporate various nanomaterials into the membrane to control its properties.

References

- Abdulhamid, M.A., Hardian, R. & Szekely, G. Carbon molecular sieve membranes with integrally skinned asymmetric structure for organic solvent nanofiltration (OSN) and organic solvent reverse osmosis (OSRO). Applied Materials Today 28, 101541 (2022).| article

You might also like

Chemical Engineering

Urban air pollution goes up in smoke

Chemical Engineering

Rethinking machine learning for frontier science

Chemical Engineering

Magnetic nanoparticles capture microplastics from water

Chemical Engineering

Biogas upgrading goes with a swing

Chemical Engineering

Stronger, lighter, cheaper: a new route to carbon fiber production

Chemical Engineering

Unveiling the role of biomass-burning aerosols in atmospheric reactions

Chemical Engineering

Slashing industrial emissions using a hybrid model approach

Chemical Engineering