Chemical Engineering

Electrochemical cell harvests lithium from seawater

The system offers an economical way to source essential battery material.

Lithium is a vital element in the batteries that power electric vehicles, but soaring lithium demand is expected to exhaust land-based reserves by 2080. KAUST researchers have now developed an economically viable system that can extract high-purity lithium from seawater.

The oceans contain about 5,000 times more lithium than the land but at extremely low concentrations of about 0.2 parts per million (ppm). Larger ions, including sodium, magnesium and potassium, are all present in seawater at much higher concentrations; however, previous research efforts to tease lithium from this mixture have yielded little.

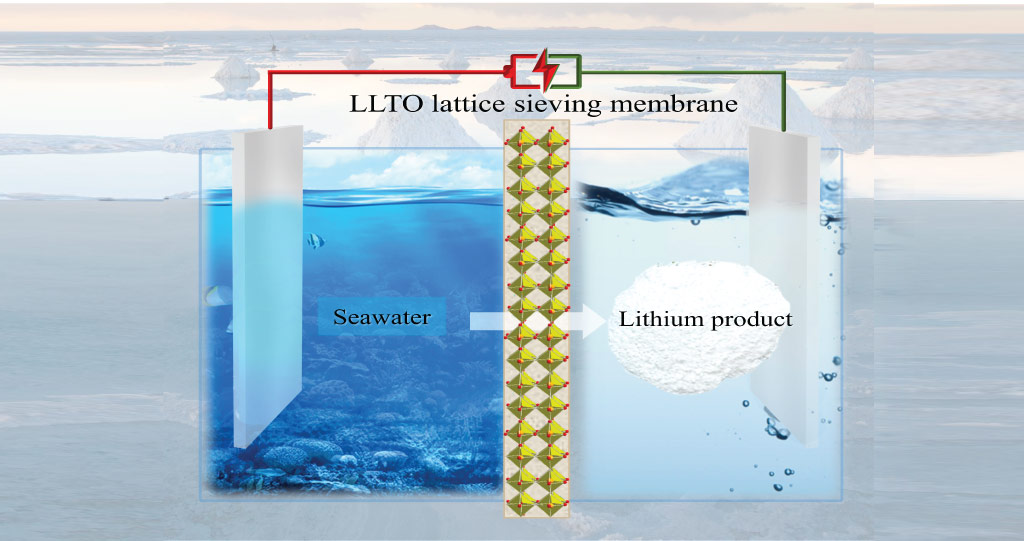

The electrochemical cell designed by the KAUST team separates lithium ions from seawater while also producing valuable hydrogen and chlorine gas.

© Li et al. (2021). Published by The Royal Society of Chemistry

The KAUST team solved this problem with an electrochemical cell containing a ceramic membrane made from lithium lanthanum titanium oxide (LLTO). Its crystal structure contains holes just wide enough to let lithium ions pass through while blocking larger metal ions. “LLTO membranes have never been used to extract and concentrate lithium ions before,” says postdoc Zhen Li, who developed the cell.

The cell contains three compartments. Seawater flows into a central feed chamber, where positive lithium ions pass through the LLTO membrane into a side compartment that contains a buffer solution and a copper cathode coated with platinum and ruthenium. Meanwhile, negative ions exit the feed chamber through a standard anion exchange membrane, passing into a third compartment containing a sodium chloride solution and a platinum-ruthenium anode.

The researchers tested the system using seawater from the Red Sea. At a voltage of 3.25V, the cell generates hydrogen gas at the cathode and chlorine gas at the anode. This drives the transport of lithium through the LLTO membrane, where it accumulates in the side-chamber. This lithium-enriched water then becomes the feedstock for four more cycles of processing, eventually reaching a concentration of more than 9,000 ppm. Adjusting the pH of this solution delivers solid lithium phosphate that contains mere traces of other metal ions — pure enough to meet battery manufacturers’ requirements.

The researchers estimate that the cell would need only US$5 of electricity to extract 1 kilogram of lithium from seawater. The value of hydrogen and chlorine produced by the cell would more than offset this cost, and residual seawater could also be used in desalination plants to provide freshwater.

“We will continue optimizing the membrane structure and cell design to improve the process efficiency,” says group leader Zhiping Lai. His team also hopes to collaborate with the glass industry to produce the LLTO membrane at large scale and affordable cost.

References

-

. Li, Z., Li, C., Liu, X., Cao, L., Li, P., Wei, R., Li, X., Guo, D., Huang, K-W. & Lai, Z. Continuous electrical pumping membrane process for seawater lithium mining. Energy and Environmental Science 14, 3152-3159 (2021).| article

You might also like

Chemical Engineering

Urban air pollution goes up in smoke

Chemical Engineering

Rethinking machine learning for frontier science

Chemical Engineering

Magnetic nanoparticles capture microplastics from water

Chemical Engineering

Biogas upgrading goes with a swing

Chemical Engineering

Stronger, lighter, cheaper: a new route to carbon fiber production

Chemical Engineering

Unveiling the role of biomass-burning aerosols in atmospheric reactions

Chemical Engineering

Slashing industrial emissions using a hybrid model approach

Chemical Engineering