Electrical Engineering

Tiny tuner turns heat into power

Sustainable energy generation boosted by a nanoscale device that converts thermal infrared radiation to an electrical current.

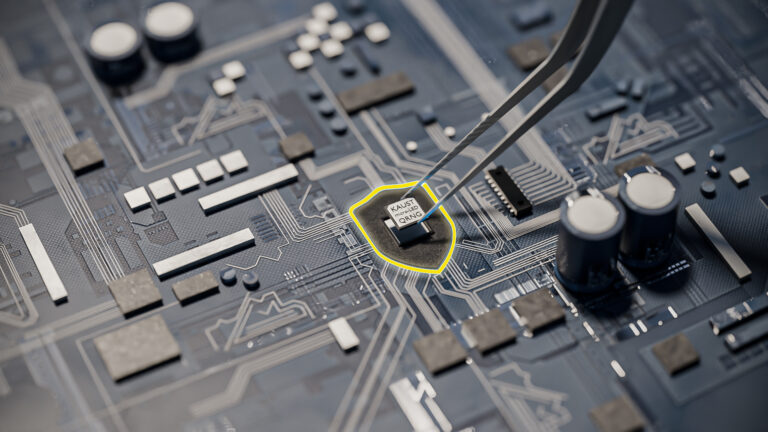

SEM image of the nanoantenna array at the heart of KAUST’s nano-rectenna. The tips of gold triangles that form the antennas are spaced by a gap of just 50nm.

© KAUST

A nanoscale integrated device that efficiently harvests energy from infrared thermal radiation has been developed by researchers in Saudi Arabia. The device captures the mid-infrared radiation that is emitted as waste heat from industrial equipment — in steam generation, metal melting and other applications — and turns it into useful electricity to help satisfy growing requirements for alternative and renewable forms of energy.

Known as the “nano-rectenna”, the device was designed and fabricated by Mena Gadalla and Atif Shamim from the Computer, Electrical and Mathematical Science and Engineering Division at KAUST with a collaborator from Prince Sultan Advanced Technology Research Institute at King Saud University.

While solar cells can convert visible light into electricity, their efficiency is quite poor. “The novel aspect of our device is that it treats the infrared or waste heat as an electromagnetic radiation which can be collected by a nano-antenna and converted into electricity through an integrated rectifier,” explains Shamim. “This approach has no theoretical efficiency limitations, in contrast to the solar cells approach”.

The rectenna is comprised of two parts — a rectifier and an antenna — from which it takes its name. The device’s nanoscale tertahertz antenna is tuned to receive and strongly enhance infrared electrical fields at around 10 microns in wavelength (corresponding to a frequency of 28.3 THz) which are emitted by warm objects. A very fast response rectifying diode then turns the quickly-oscillating THz field into an electrical direct current (DC).

Previous versions of rectennas have been able to harvest microwaves which have a gigahertz frequency. However, designing a device that works at infrared wavelengths is challenging as it requires a nanoscale antenna plus a rectifier that operates at terahertz speeds.

The researchers set out to first optimize their design of electromagnetic antenna. They used a resonant bowtie antenna fabricated by electron beam lithography. The antenna consists of two triangular shaped gold nano-patches, 100 nanometers thick, which are pointing towards each other and separated by a tiny gap (~50 nanometers).

The antenna was fabricated on a silicon dioxide substrate which lies above a layer of silicon with a thin gold back-reflector. Infrared waves coupled to the antenna are captured and produce a highly enhanced electric field in the antenna’s gap that oscillates at a frequency in the terahertz band.

A metal-insulator-metal (MIM) tunneling diode based on a very thin (0.7nm) layer of copper oxide sandwiched between gold and copper is then located at the antenna gap to rectify this terahertz signal and turn it into a useful DC signal.

References

- Gadalla M.N., Abdel-Rahman M. & Shamim A. Design, optimization and fabrication of a 28.3 THz nano-rectenna for infrared detection and rectification. Scientific Reports 4, 4270 (2104). | article

You might also like

Electrical Engineering

Quantum dot lasers outshine expectations

Bioengineering

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

Green quantum computing takes to the skies

Electrical Engineering

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering