Electrical Engineering

Cleaning nanowires to get out more light

A simple chemical surface treatment improves the performance of nanowire ultraviolet light-emitting diodes.

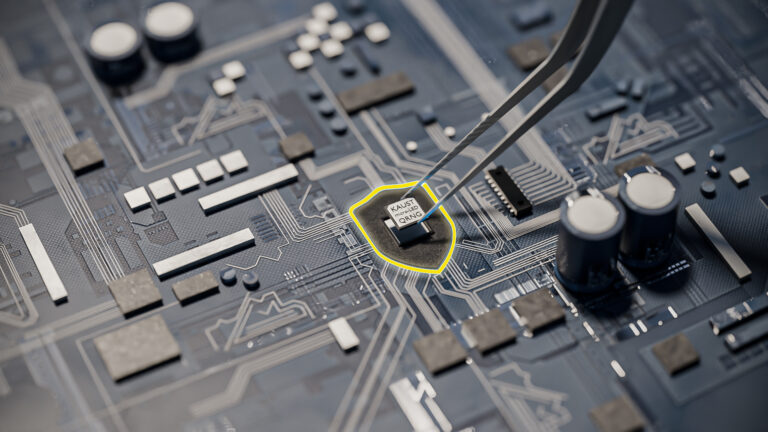

A technique for reducing the loss of light at the surface of semiconductor nanostructures has been demonstrated by scientists at KAUST.

Some materials can efficiently convert the electrons in an electrical current into light. These so-called semiconductors are used to create light-emitting diodes or LEDs: small, light, energy-efficient, long-lasting devices that are increasingly prevalent in both lighting and display applications.

The color, or wavelength, of the emitted light can be determined by choosing the appropriate material. Gallium arsenide, for example, emits predominantly infrared light. For shorter wavelengths that move into the blue or ultraviolet region of the spectrum, scientists have turned to gallium nitride. Then, to tune down the emission wavelength, aluminum can be added, which alters the spacing between the atoms and increases the energy bandgap.

However, numerous factors prevent all the radiation created in the semiconductor escaping the device to act as an efficient light source. Firstly, most semiconducting materials have a high refractive index, which makes semiconductor–air interfaces highly reflected—at some angles all light bounces backwards in a process known as total internal reflectivity. A second limitation is that imperfections at the surface act as traps that reabsorb the light before it can escape.

Postdoc Haiding Sun and his KAUST colleagues, including his supervisor, Assistant Prof. Xiaohang Li, Prof. Boon Ooi and Assistant Prof. Iman Roqan, have developed LEDs that are made up of a tight array of dislocation-free nanometer-scale aluminum-gallium-nitride nanowires on a titanium-coated silicon substrate. More light can be efficiently extracted due to the presence of the air gaps between nanowires via scattering. The trade-off however is that arrays of nanowires have a larger surface area than a planar structure. “Because of the large surface-to-volume ratio of nanowires, their optical and electrical properties are highly sensitive to their surroundings,” says Sun. “Surface states and defects will lead to low-efficiency light-emitting devices.”

Sun and the team show that treating the nanowires in a diluted potassium-hydroxide solution can suppress the surface reabsorption by removing dangling chemical bonds and preventing oxidization. Their results showed that a 30 second treatment led to a 49.7 percent enhancement in the ultraviolet light output power as compared with an untreated device.

“We aim to improve our device’s performance in several ways,” says Sun. “For example, we will optimize the nanowire growth conditions, we will use quantum-well structures in the active region and we will use different metal substrates to improve the light-extraction efficiency.”

References

- Sun, H., Shakfa, M.K., Muhammed, M.M., Janjua, B., Li, K.-H., Lin, R., Ng, T.K., Roqan, I.S., Ooi, B.S. & Li, X. Surface-passivated AlGaN nanowires for enhanced luminescence of ultraviolet light emitting diodes. ACS Photonics 5, 964-970 (2017).| article

You might also like

Bioengineering

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

Green quantum computing takes to the skies

Electrical Engineering

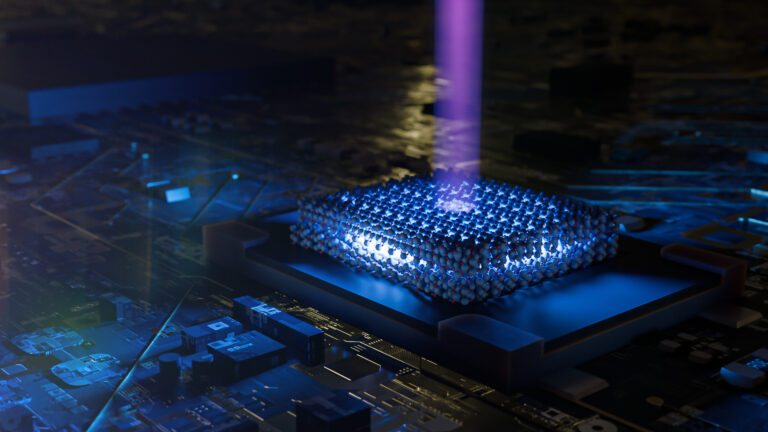

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering

New tech detects dehydration by touching a screen

Electrical Engineering