Electrical Engineering

Windows could take the heat

Generators embedded in windows produce electricity from the temperature differential between an air-conditioned interior and a sunny outside world.

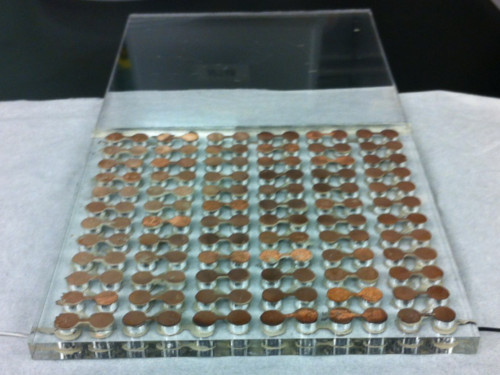

A prototype thermoelectric 14” x 14” window expanding the original concept to 72 pairs of bismuth telluride and antimony telluride thermopiles

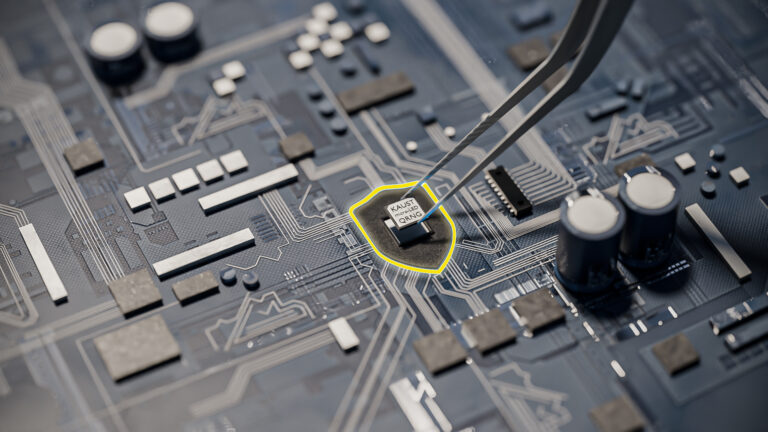

© KAUST

Air conditioning systems that make us comfortable on the hottest days consume vast quantities of energy that contribute to global warming and, ironically, the prospect of even hotter days. Now researchers from KAUST have devised a method to claw back some of this energy.

Thermoelectric materials enable electrical energy to be created from the flow of charge carriers induced by a thermal gradient. Offering a clean and quiet source of energy, thermoelectrics are well known but their application has stalled, requiring the right ‘mix’ to ensure they are practical and efficient. Recent advances in nanotechnology have opened a range of new opportunities.

Thermoelectrics depends on the balance between electrical and thermal conductivity: electrical conductivity needs to increase while thermal conductivity needs to reduce. The trick lies in controlling these properties independently of each other. Associate Professor Muhammad Hussain and Ph.D student Salman Inayat tackled this challenge by combining ‘common’ thermoelectric materials with nano manufacturing to reduce thermal conductivity by enhancing the photo scattering of materials.

The researchers treated off-the-shelf thermoelectric powders of antimony telluride and bismuth telluride. The resultant materials showed promise when tested in a thermoelectric generator device. They used a ball mill to grind the powders before hot pressing to produce pellets with more grain boundaries which provided more scattering sites for the heat carriers (phonons) and reduced thermal conductivity. Electrical charge carriers were introduced simultaneously, which improved electrical conductivity.

“Adding sulfur before ball milling introduced even more sites to deflect phonons and also diluted the concentration of deleterious low energy charge carriers,” explained Hussain. “However we found that adding the sulfur reduced the performance of bismuth telluride.”

The team chose the two best performing ball-milled materials —bismuth telluride and sulfur-alloyed antimony telluride — and produced a prototype thermoelectric generator. Two pellets of each material were placed inside pre-drilled holes in window glass. The pellets were of exactly the same thickness as the glass and thus directly exposed to external and internal temperatures on each side. All the pellets were connected to each other with copper wires to complete the electrical generator.

Inayat recorded an output power of 0.112 microWatts at a temperature difference of 23.5 degrees Celsius. “We could improve on this performance by more precisely engineering the connecting wires,” says Inayat. They calculated that they achieve a power output of 304 Watts by scaling up their device across 9 square meters of glass.

A temperature gradient of 23.5 degrees Celsius across a window would only exist in the hottest countries. In more temperate climates, with smaller differentials, the technology could extract sufficient electricity for green building technologies. This technology could also suit cold climates, where electricity can be generated at the interface between a cooler exterior and warmer interior.

References

- Inayat, S.B., Rader, K. R. & Hussain, M. M. Nano-materials enabled thermoelectricity from window glasses Scientific Reports 2, 481 (2012). | article

You might also like

Bioengineering

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

Green quantum computing takes to the skies

Electrical Engineering

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering

New tech detects dehydration by touching a screen

Electrical Engineering