Electrical Engineering

Bent, but not broken

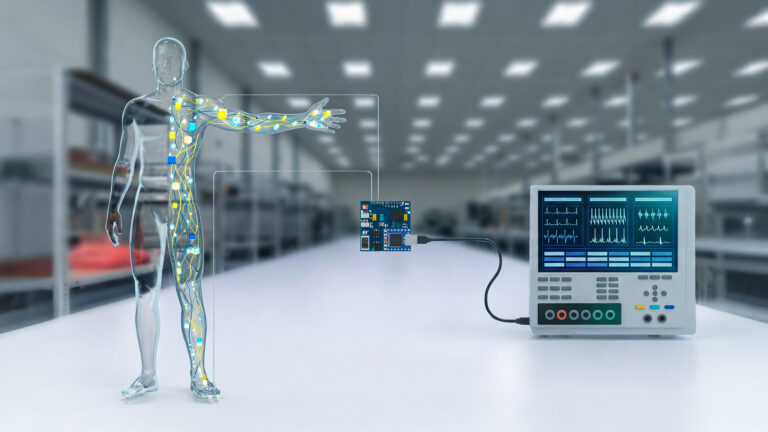

Bendable electronics could help make robust wearable devices that can continuously monitor a person’s health.

Bendable electronic circuits have potential applications in healthcare technologies that can be attached directly to the skin

© Muhammad Mustafa Hussain

Effective wearable technology to monitor health indicators is a step closer after KAUST researchers developed flexible electronic circuits that continue to work even when bent and folded like a thin piece of paper.

While there has been rapid progress made in flexible electronics, the challenge remains to find suitable materials that retain excellent electrical performance even when bent or strained. Most electronic devices are currently based on silicon, which has excellent electrical properties as well as being abundant and cheap. However, silicon’s usefulness is limited because it is unyielding and brittle.

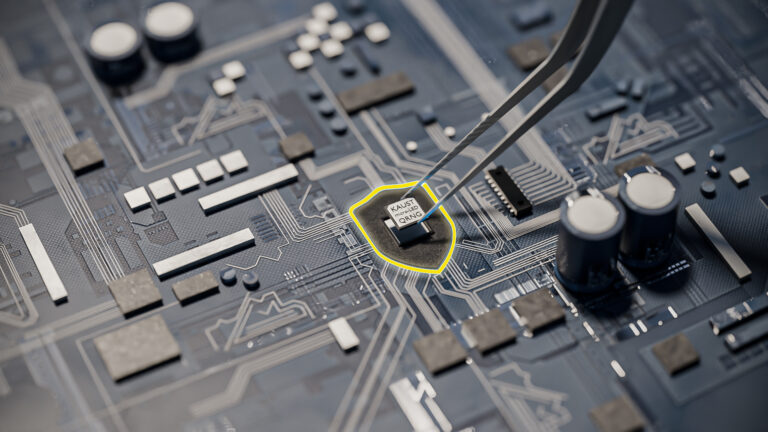

Muhammad Mustafa Hussain from the Division of Computer, Electrical and Mathematical Science and Engineering and colleagues have now designed a flexible electronic circuit, which keeps functioning even when bent sharply many times. Their approach was to first create the electronic components on a conventional silicon substrate and then show how these can be transposed onto a more malleable substrate1.

Hussain explains that bendable circuits have many potential uses — such as devices that could be attached directly to the skin to continuously monitor a patient’s pulse, blood pressure or blood glucose level, negating the need for needles or finger pricks. A device’s reliability, however, is compromised by repeated flexing of the circuit. “The finger joint and the shoulder have different bending radii and, in the case of the jaw, a flexible device bends many times as we talk and eat,” says Hussain.

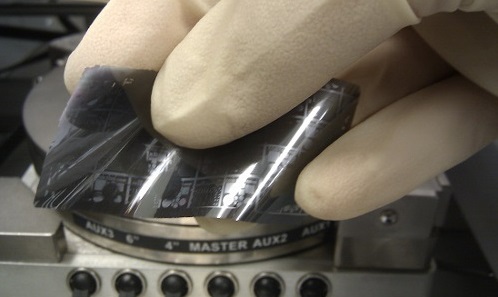

Building on past success with metal oxide semiconductors, Hussain’s team set out to measure how acute and repetitive bending affects the performance of these flexible circuits. They fabricated their capacitors on a rigid silicon substrate then placed the sample in a gas that etches away the silicon, leaving only a thin fabric that is both flexible and semi-transparent. The researchers then put these circuits under a series of mechanical stresses to investigate how they affect their electrical properties.

First, they measured an essential capacitor property known as the breakdown voltage — the maximum voltage that can be applied across the device before it stops functioning properly. Surprisingly, they found that increasing the strain produced better performance. For example, when the capacitors were bent 180 degrees their device proved to be three times less prone to breakdown when bent at the small radius of curvature of 5 millimeters compared to a wider 50 millimeters curvature.

They then tested the decline in the device’s performance with repeated flexing. When the device was bent 50 times the function was reduced — the breakdown voltage fell to about 12 percent of its initial value — and after 100 bends it failed completely. The researchers attributed this to the fracture of the fabric, however, and now plan to try adding polymeric support to the final device to increase its endurance.

References

- Ghoneim, M. T., Kutbee, A., Ghodsi Nasseri, F., Bersuker, G. & Hussain, M. M. Mechanical anomaly impact on metal-oxide-semiconductor capacitors on flexible silicon fabric. Applied Physics Letters 104, 234104 (2014).| article

You might also like

Bioengineering

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

Green quantum computing takes to the skies

Electrical Engineering

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering

New tech detects dehydration by touching a screen

Electrical Engineering