Electrical Engineering

Flexing for the next silicon wave

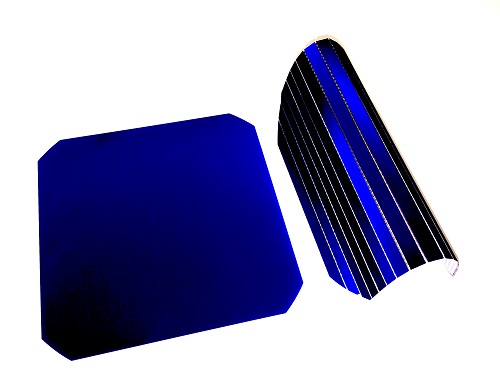

Ultrathin, rigid silicon segments that are wired through interdigitated metal contacts produce ultraflexible high-performance solar cells.

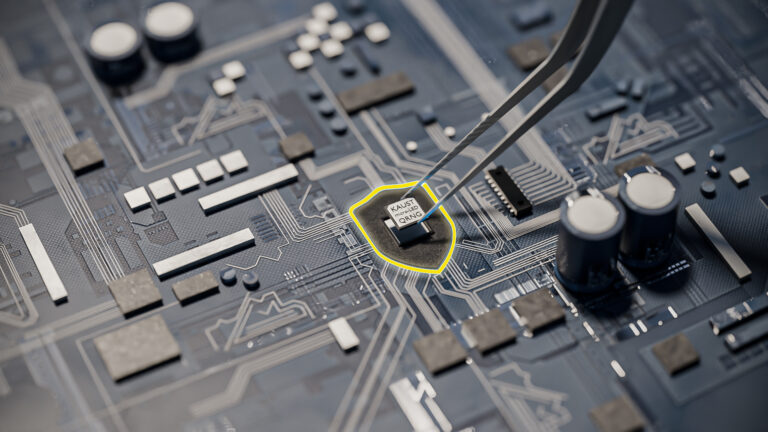

Rigid (left) and flexible (right) crystalline silicon-based solar cells.

© 2017 KAUST

A strategy that uses a screen-printed aluminium circuit to make silicon solar cells extremely flexible could enable them to become portable power sources. Developed by KAUST, such power sources could help to satisfy the growing demand for wearable and implantable devices, foldable displays and vehicle-integrated solar panels.

Crystalline silicon is naturally abundant and highly scalable and has reliable and consistent photovoltaic properties that are appealing for the development of industrial solar cells. However, its rigidity and weight have hindered its application for flexible electronics.

Attempts at enhancing material flexibility by generating thin films, while maintaining device performance, have fallen short: the resulting solar cells have shown a drop in performance for films thinner than 250 micrometers. “At this thickness, one cannot achieve flexible silicon solar cells,” says team leader, Muhammad Hussain, from KAUST.

Now, Hussain’s team has created a corrugated array comprising thin, rigid silicon segments using so-called interdigitated back contact solar cells. The segments are interconnected by screen-printed aluminum contacts. These contacts are positioned at the rear to optimize light absorption at the front of the solar cell and facilitate any modifications of the active silicon material. The array can bend and adopt various configurations, such as zigzags and bifacial structures, without cracking or losing its power conversion efficiency.

Starting from large-area crystalline silicon solar cells, the researchers etched a small portion of the cells into 140-micrometer-thick strips, while keeping the thickness of the remaining portion above 240 micrometers. “This allowed us to lower the bending radius of the cell to 140 micrometers while retaining the efficiency of the bulk (18 percent), record achievements for both silicon solar cell efficiency and bendability,” says lead author Rabab Bahabry, a graduating doctoral student from Saudi Arabia who received her bachelor’s degree in physics from King Abdulaziz University.

The researchers demonstrated that a series of five corrugated solar cells lit up multicolored light-emitting diodes. They also wrapped the cells around a glass mug to power a miniature humidity detection system placed on a plant leaf. When exposed to light from a desk lamp and humid conditions, the system turned on an LED and sent a notification to a smartphone.

The team is currently investigating ways to exploit these corrugated solar cells, which, according to Hussain, can be deployed in the most complex topologies. “Our approach is suitable for the Internet of Things and can meet a wide application spectrum,” he says.

References

- Bahabry, R.R., Kutbee, A.T., Khan, S., Sepulveda, A.C., Wicaksono, I., … & Hussain, M.M. Corrugation architecture enabled ultra-flexible wafer-scale high-efficiency monocrystalline silicon solar cell. Advanced Energy Materials 8, 1702221 (2018).| article

You might also like

Electrical Engineering

Quantum dot lasers outshine expectations

Bioengineering

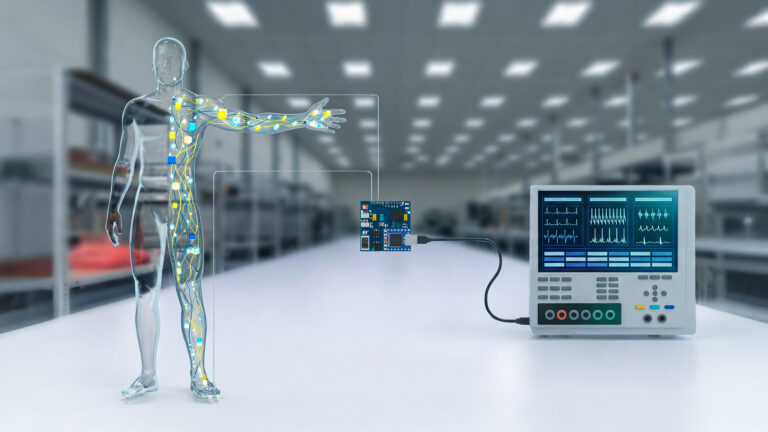

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

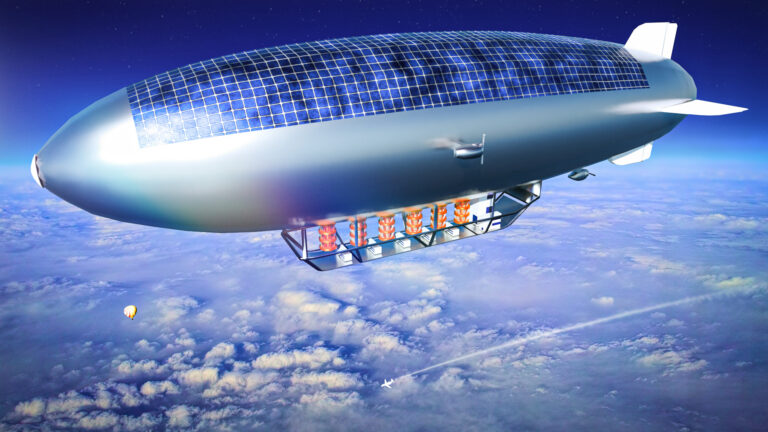

Green quantum computing takes to the skies

Electrical Engineering

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering