Electrical Engineering

Stretching toward energy efficiency

Deformable thermoelectric materials add a new twist to the design of energy-scavenging devices.

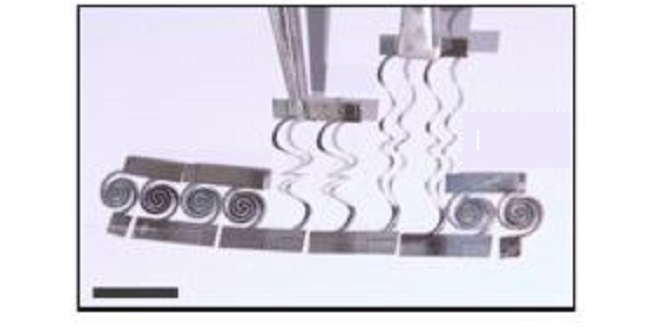

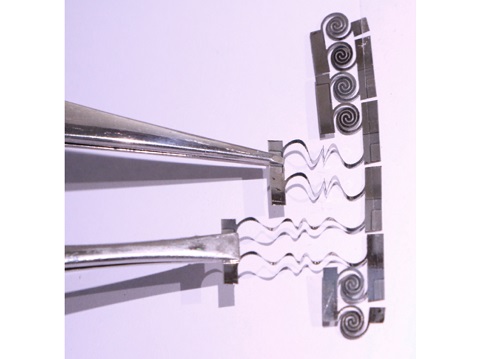

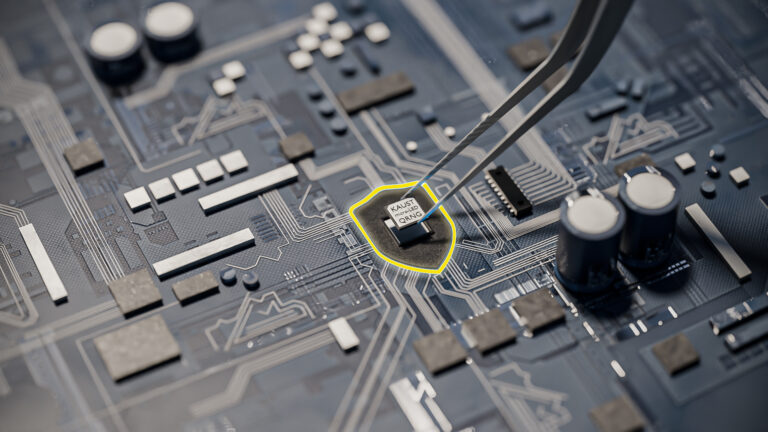

A bank of helical-cut thermoelectric materials being stretched.

Reproduced with permission from ref 1. © 2016 Elsevier.

Adding elasticity to the impressive properties of materials known as thermoelectrics could help us conserve more power, KAUST researchers have shown1.

From laptop chips and automobile exhaust pipes to industrial machinery, for most devices, a lot of the energy they consume is lost as heat. Flexible thermoelectric materials can mop up this heat and turn it back into useful electricity that they could use to maximize electrical output.

The key to the useful behavior of thermoelectric materials, such as bismuth telluride and antimony telluride, is that when one side of the material is hot and the other side is cold, they spontaneously generate an electrical voltage. The greater the temperature gradient, the more power they generate. But to date, thermoelectric generators (TEGs) have almost invariably been made from solid blocks of thermoelectric materials.

“We envisioned that a stretchable TEG would achieve more output power as it can easily maintain a longer distance between the hot end and the cold end,” said Muhammad Hussain, Associate Professor of Electrical Engineering at KAUST, who led the research. The cold end of the stretchable TEG can be pulled further away from the heat source, maximizing the temperature gradient.

Hussain’s team made the flexible TEGs by coating bismuth telluride or antimony telluride onto a helically shaped flexible paper or polymer substrate. Hussain explained that this helical architecture is what allowed the TEG to flex and stretch in any direction while maintaining its mechanical integrity.

A simple spiral shape, made from a paper substrate (which has lower thermal conductivity than the polymer), was the best design, generating more than twice the power when stretched than when laid flat.

Hussain has a couple of initial applications in mind for his stretchy TEGs. “For wearable gadgets, they can be very useful,” he said. “Another immediate area we are looking into is thermoelectric power from ships and automobiles. Their top surface is under the sun and their bottom surface is always in the water or in the shade.”

“Stretchable TEGs could be used in almost any application where there is waste heat to be recaptured, Hussain added. Traditionally, to enhance the power production from a TEG, the thought process has singularly focused on improving the thermoelectric properties of various thermoelectric materials. We have clearly shown that the architecture of the TEG is equally important to enhancing the power production independent of the thermoelectric material used.”

References

-

Rojas, J.P., Singh, D., Conchouso, D., Arevalo, A., Foulds, I.G. & Hussain, M.M. Stretchable helical architecture inorganic-organic hetero thermoelectric generator. Nano Energy 30, 691–699 (2016).| article

You might also like

Electrical Engineering

Quantum dot lasers outshine expectations

Bioengineering

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

Green quantum computing takes to the skies

Electrical Engineering

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering