Electrical Engineering

A modern way to heal old wounds

Smart bandage technology provides instant updates on the condition of chronic wounds through a mobile phone app.

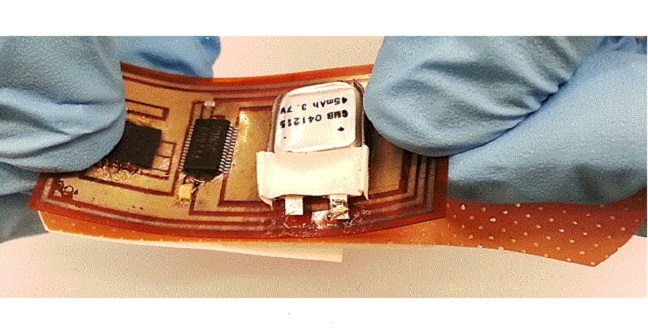

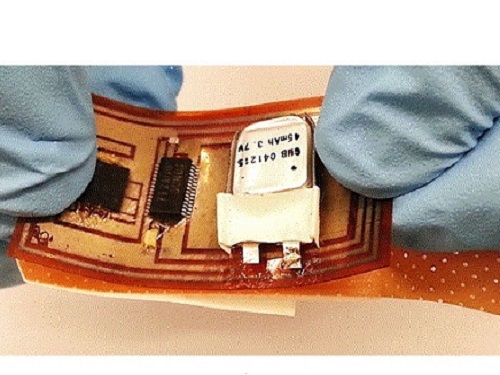

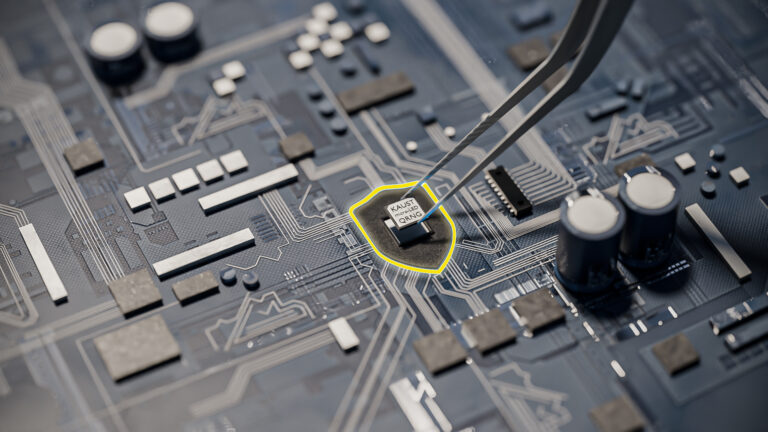

The sensor is printed on a disposable bandage strip using a low-cost inkjet printing technique. It has a detachable sticker that carries the wireless electronics and can be reused multiple times.

Reproduced with permission from ref 1© 2016 Nature Publishing Group

Injuries that fail to heal within three months, such as many diabetic foot ulcers, can require years of treatment and significant healthcare resources. A sensor-laden bandage developed by a research team at KAUST promises to reduce the burden on hospitals and enhance patient well-being by transforming how chronic wounds are monitored1.

Researchers are working on new kinds of wearable sensors that alert users outside the hospital environment of potentially concerning changes in body temperature, heart rate or blood pressure. Chronic wound monitoring, however, has received less attention from device designers. One problem is that subtle forces that disrupt healing, such as bacterial infections, are difficult to detect with automated systems.

Associate Professor Atif Shamim from the Electrical Engineering program at KAUST and his Ph.D. student Muhammad Farooqui set out to design a smart bandage that monitors three parameters simultaneously—bleeding, pH levels and external pressure—to provide realtime updates on wound status using wireless technology.

The team’s consultations with medical professionals revealed that variations in a wound’s pH level may indicate bacterial attacks. Combining this data with warnings about excess blood or pressure could alert users of the need for attention and help prevent ulcers from becoming chronic. Producing multi-component sensors on stretchy bandage strips required a rethink about traditional microscale fabrication. Shamim and Farooqui used inkjet printing to directly pattern conductive carbon and silver ink onto plastic substrates.

“Inkjet printing is a very suitable method to put electronics on delicate, flexible and unconventional mediums,” Shamim said. “It’s a low-cost manufacturing process, so it helps to keep this technology affordable and disposable.”

The researchers separated their prototype into two parts. They printed resistive and capacitive sensors onto a commercial bandage that could be discarded after use and then crafted wireless communication components, such as silver antenna patterns, onto a polymer film that easily sticks or detaches from the bandage. Making the wireless circuits reusable helps reduce the cost of the device even further, noted Shamim.

On-body testing showed the bandage could communicate with a smartphone-like receiver up to 60 meters away, sending warnings such as “change bandage” when simulated blood conditions demanded it. Furthermore, the device was robust enough to be worn for an extended time and for its wearer to bend often.

“With our smart bandage, long-term collection of medical data becomes reasonable and convenient,” said Shamim. “This could change how the healthcare industry operates, and we are working to translate it into a useful real-world product for chronic wound sufferers.”

References

-

Farooqui, M. F & Shamim, A. Low cost inkjet printed smart bandage for wireless monitoring of chronic wounds. Scientific Reports 6, 28949 (2016).| article

You might also like

Electrical Engineering

Quantum dot lasers outshine expectations

Bioengineering

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

Green quantum computing takes to the skies

Electrical Engineering

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering