Electrical Engineering

New lessons for an old magnet

The surface structure of magnetite is crucial to its performance in magnetism-based electronic applications.

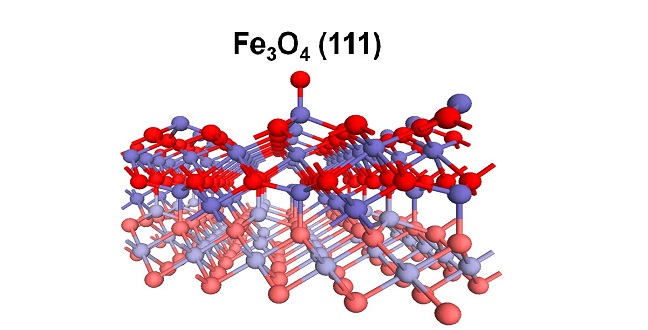

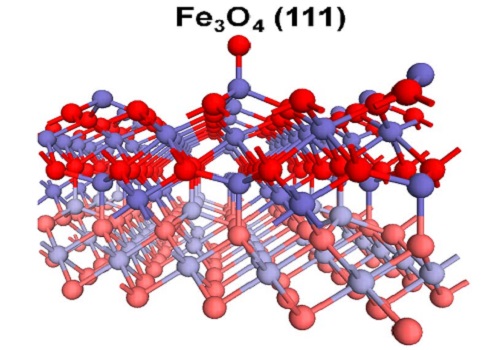

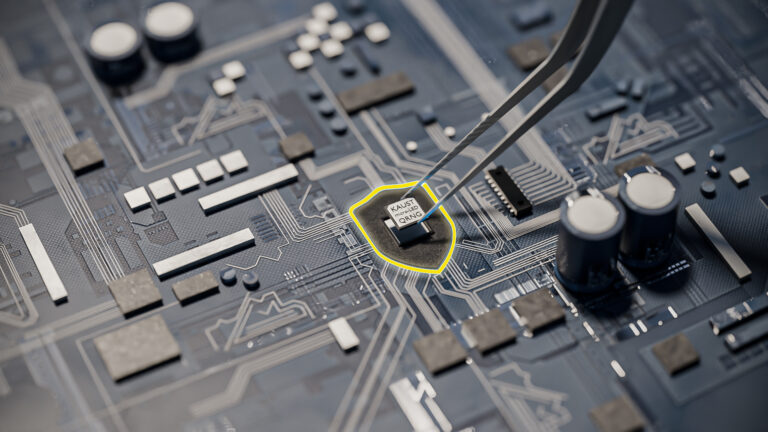

A cut through magnetite along the direction studied (111 surface). The precise atomic termination of the material on this surface and the presence of small imperfections can stabilize its magnetic properties.

Reproduced with permission from Ref 1© 2015 American Chemical Society

The effect of surface structure on the magnetic properties of an iconic magnetic material has been uncovered by researchers from KAUST. The findings show how cutting through the atomic structure of a surface with crystals of magnetite and small surface imperfections could lead to better control of the magnetic properties1.

Magnetite is one of the oldest magnetic materials known to humans and has been used to produce compass needles for thousands of years. Contemporary interest in the material focuses on its use for applications based on the magnetic properties of electrons, or their spin. For these spintronic applications, the focus is on the up and down orientations of the electron spin rather than the control of positive and negative electrical charges.

Its properties make magnetite an interesting material for spintronics, noted Jean-Luc Brédas, from the Solar & Photovoltaics Engineering Research Center (SPERC). Brédas also led the research team in their work.

“One of the major appeals of magnetite relates to the fact that it is a half-metal,” explained Brédas. “Half-metallic materials have electrons that occupy only one spin channel—say, up spins. In principle, this leads to 100 percent polarization.” A full polarization of the electron spins in devices is necessary for spin-based devices, as otherwise there would be detrimental noise effects.

Despite such theoretical promises, magnetite does not reach this potential in practice. The problem is at the interface to other materials, where it is necessary to maintain spin polarization of electrons passing from one material to another.

To understand the reasons for this underperformance, the researchers performed sophisticated computational calculations of the magnetite surface using a theoretical model that is able to account for the smallest interactions between the material’s electrons.

Those computations reveal that the surface electronic states for certain atomic terminations are more stable than others, and that this stability might be improved even further through a small number of imperfections. This also affects the properties of the electrons, noted Brédas.

“The results show that the preparation conditions dramatically alter the spin polarization of the surface layers,” he said.

These findings have immediate implications towards improving and stabilizing magnetite surfaces. For example, preparing the right surface would allow the material to be used as an electrode in organic light-emitting diodes and in spintronic devices. Beyond this, the improved understanding of the surface properties might have further benefits, as this knowledge could be exploited for other improvements, such as corrosion resistance.

References

- Noh, J., Osman, O.I., Aziz, S.G., Winget, P. & Brédas, J-L. Magnetite Fe3O4 (111) surfaces: impact of defects on structure, stability, and electronic properties. Chemistry of Materials 27, 5856−5867 (2015).| article

You might also like

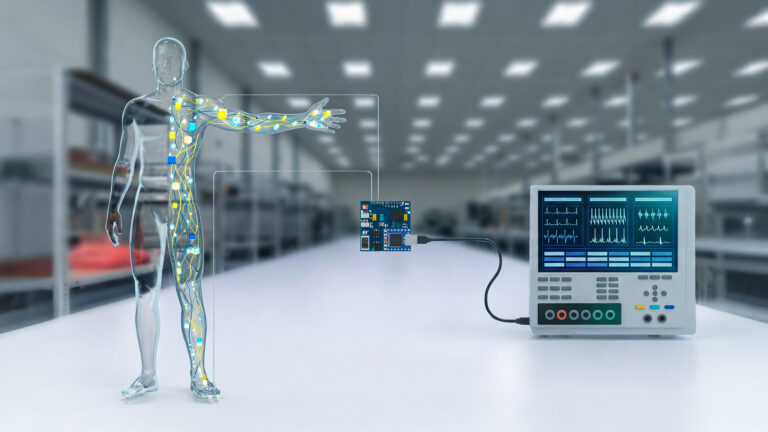

Bioengineering

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

Green quantum computing takes to the skies

Electrical Engineering

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering

New tech detects dehydration by touching a screen

Electrical Engineering