Electrical Engineering

Lasers bridge the rainbow

Subtle changes to the composition of a semiconductor structure enable laser light at colors previously not thought possible.

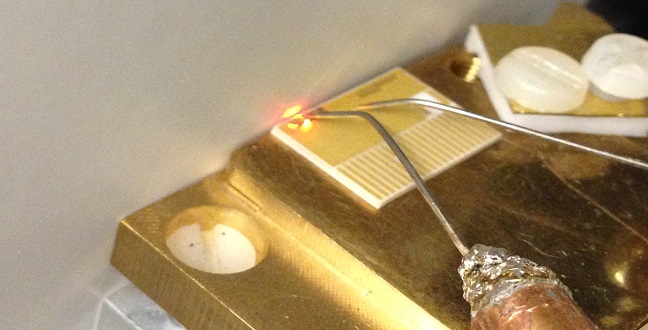

Annealing a semiconductor structure enables researchers to tune the color of a laser into the orange parts of the spectrum .

© 2015 KAUST

Micrometer-scale lasers that emit orange light have been created by researchers at KAUST1. Orange laser light is useful for diverse applications ranging from horticulture to optical communications, but previous attempts to create an orange laser were not commercially practical.

Conventional lasers that produce orange-yellow light use a gas or a nonlinear crystal as the light-producing medium and can be as small as tens of centimeters or can fill a room. Semiconductors lasers, however, are compact, and can be just a few micrometers in size.

The drawback of the semiconductor approach is that the color of light produced by such devices is determined by the intrinsic properties of the material. Because there are only a few suitable semiconducting materials, there is a limited selection of emission wavelengths.

Boon Ooi of the Computer, Electrical and Mathematical Science and Engineering Division, and his colleagues produced a laser that creates orange light by making subtle compositional changes of a structure based on InAlAsP materials.

“We have fabricated high-performance semiconductor lasers that bridge the wavelength gap of visible light semiconductor lasers,” Ooi said.

Previous orange semiconductor-based lasers were created using complicated techniques that could not be commercialized. Ooi and the team tried a much simpler route. Their device incorporated a quantum well, a thin layer of InGaP just six nanometers wide that was sandwiched between thicker barriers of InAlGaP.

Quantum wells emit light at a wavelength in between that produced by either material on its own, and the exact emission color can be changed by altering the composition and strain properties of the well.

Ooi and the team further tuned the emission wavelength using a simple thermal annealing process. This involved quickly heating the semiconductor up to 950 degrees Celsuis for 30 seconds. Each repetition of this process gradually reduced the emission wavelength, with five cycles shifting the as-grown wavelength of 640 nanometers to 601 nanometers. This happens because the annealing made atoms slowly diffuse from the barrier to the well and relaxed the grown-in strain in the well.

With their material optimized, the researchers fabricated a one-millimeter long laser cavity and attached electrical contacts. Their device worked at room temperature and generated 46 milliwatts of orange light.

The devices could be useful for producing white-light sources. “High color quality lighting can be produced using red-yellow-green-blue lasers, or by mixing blue-yellow to generate white light,” said Ooi. “The demonstration of an orange laser will bring us one step closer to demonstrating yellow semiconductor lasers.”

References

- Majid, M.A., Al-Jabr, A.A., Oubei, H.M., Alias, M.S., Anjum, D.H., Ng, T.K. & Ooi, B.S. First demonstration of InGaP/InAlGaP based orange laser emitting at 608 nm. Electronics Letters 51, 1102–1104 (2015).| article

You might also like

Electrical Engineering

Quantum dot lasers outshine expectations

Bioengineering

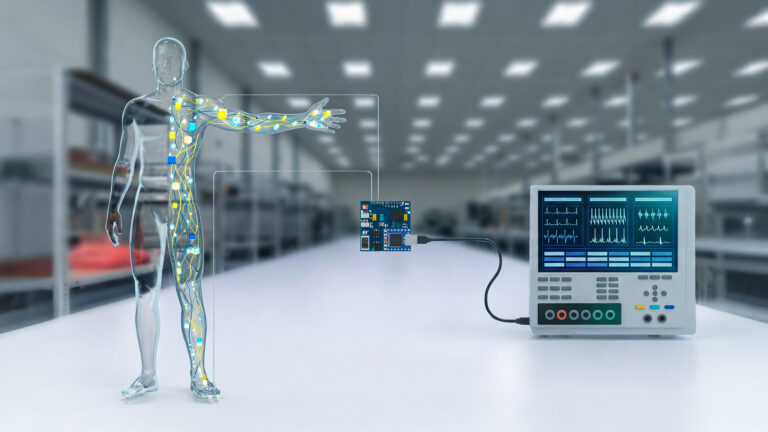

Self-aware biosensors boost digital health monitoring

Bioengineering

Smart patch detects allergies before symptoms strike

Computer Science

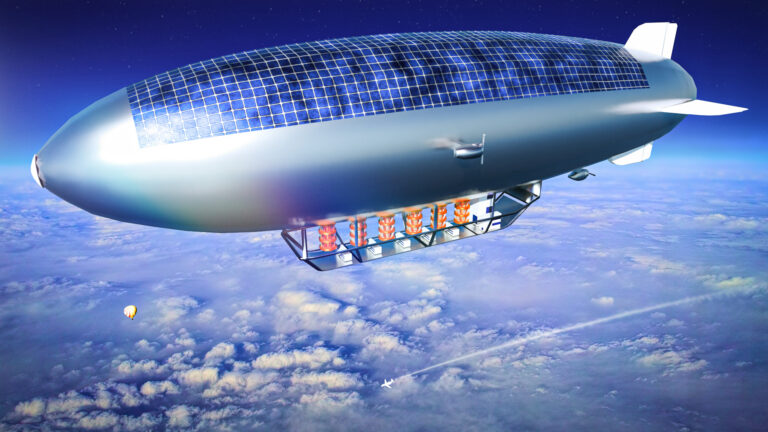

Green quantum computing takes to the skies

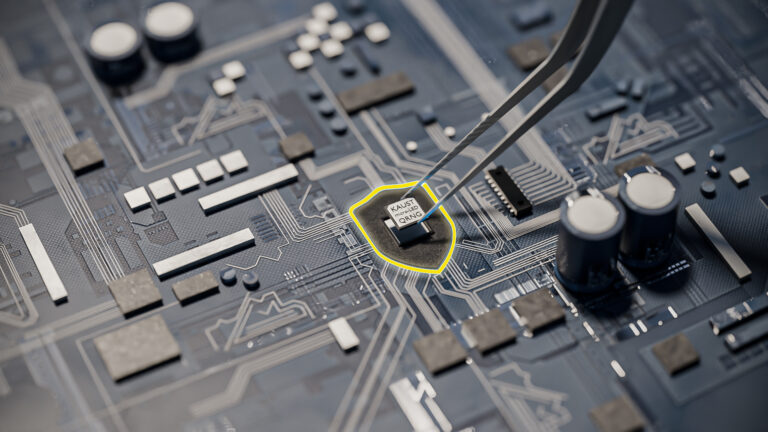

Electrical Engineering

Micro-LEDs boost random number generation

Bioengineering

Sensing stress to keep plants safe

Computer Science

Sweat-sniffing sensor could make workouts smarter

Electrical Engineering