Chemistry

MOFs with smaller pores better select gases

Making the pores of metal-organic frameworks smaller could open up new opportunities in gas separation techniques.

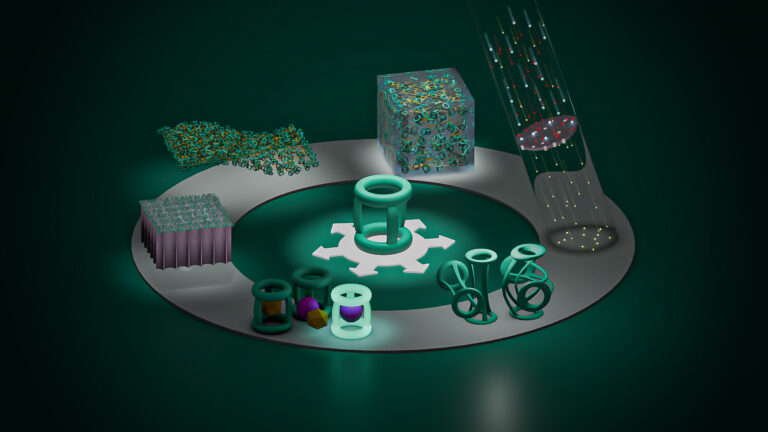

The new method can generate exceptionally stable crystals of MOFs.

© 2015 KAUST

Most new research into metal organic frameworks (MOFs) — porous and flexible hybrid organic-inorganic materials that are highly selective for gas adsorption and catalysis — has focused on increasing the size of the pores.

Researchers from the KAUST have countered that trend by reducing the pore size of MOFs to demonstrate useful new ways to separate molecules in a gaseous mixture.

Mohamed Eddaoudi from KAUST is a world leader in designing, synthesizing and exploring the remarkable properties of MOFs. These hybrid materials contain metal ions or metallic clusters held together by organic chemical groups known as linkers. Varying the linkers and/or the metallic centers allows the size of pores within MOF crystals to be fine-tuned to perform many useful functions including highly selective gas adsorption and catalysis.

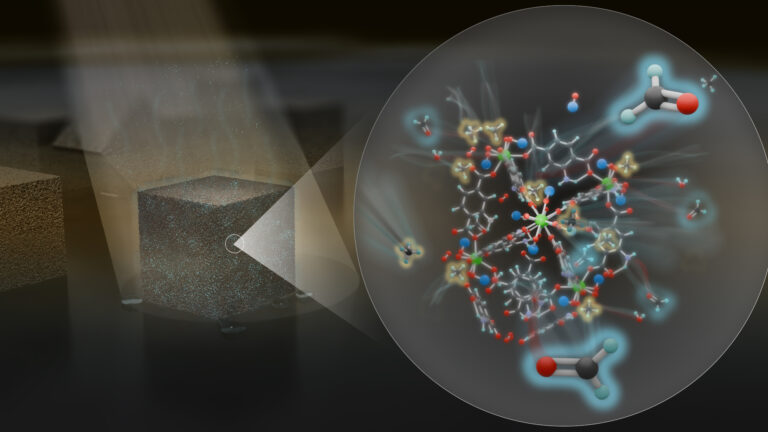

The KAUST research team has found that precisely tuned reductions in pore size offer useful new ways to separate molecules in a gaseous mixture. Their new MOFs contain ions of the rare-earth elements europium, terbium and yttrium, combined with 1,4-napthalenedicarboxylate (1,4-NDC) as the organic linker.

Eddaoudi explains that these MOFs were developed from earlier versions which have triangular windows that allow guest molecules to enter the inner pore system. The 1,4-NDC is a bulkier linker, and was chosen to make the windows smaller, thus modifying the MOF’s properties as desired.

“Our methods can generate exceptionally stable MOFs with contracted pore sizes that have been shown to achieve efficient separation of several gas mixtures,” says Eddaoudi (see image). Instead of a simple physical sieving process, the separation seems to be largely driven by “adsorption kinetics” — the different rates at which molecules are adsorbed on to the internal surfaces of the structures.

The potential of these MOFs with contracted pores was demonstrated for the purification of natural gas. The small methane molecules (CH4) that are the main valuable component of natural gas are generally mixed with relatively larger molecules including ethane, propane and butane. “Cost-effective purification of methane remains an ongoing challenge, and current methods are energy intensive,” Eddaoudi explains. This work now suggests that using MOFs either as bulk sorbents or as membranes may offer a more efficient and cheaper alternative.

Eddaoudi’s group also recently devolved MOFs in membrane form, giving them an advantage in the exploration of membranes made from MOFs tuned by the contractions of pore sizes achieved by this latest innovation.

“We believe that MOFs are the most promising candidate materials for incorporation functionality by design,” says Eddaoudi.

References

- Xue, D-X., Belmabkhout, Y., Shekha, O., Jiang, H., Adil, K., Cairns, A. & Eddaoudi, M. Tunable rare earth fcu-MOF platform: access to adsorption kinetics driven gas/vapor separations via pore size contraction. Journal of the American Chemical Society 137, 5034–5040 (2015).| article

You might also like

Chemistry

Turning infrared solar photons into hydrogen fuel

Applied Physics

Natural polymer boosts solar cells

Chemistry

Disruptive smart materials flex with real world potential

Chemistry

Catalysts provide the right pathway to green energy

Chemistry

Hollow molecules offer sustainable hydrocarbon separation

Chemistry

Maximizing methane

Chemistry

Beating the dark current for safer X-ray imaging

Chemical Engineering